Protective clothing is clothing designed to protect either the wearer’s body or other items of clothing from hazards such as heat, chemicals, and infection. Protective clothing is any clothing specifically designed, treated, or fabricated to protect personnel from hazards that are caused by extreme environmental conditions, or a dangerous work environment.

Also, special clothes may protect the working environment from pollution and/or infection from the worker, for example in a microchip factory. The protection may also be important in both ways, as with the use of disposable gloves by surgeons and dentists.

Types of protective clothing

Types of protective clothing: Have you ever been to a hospital or doctor’s office and saw someone donning layers until they were covered head to toe? They likely went immediately into a room and emerged with some or none of what they had on before.

What they covered themselves with is known as personal protective equipment. Personal protective equipment (PPE) is used to prevent exposure to infectious material. In other words, it acts as a barrier to stop the spread of germs. Infectious material can be airborne, in the form of droplets, or happen through contact routes.

The different types of protective clothing are:

Protective clothing for medical use

Protective clothing for medical use:

Several fluid-resistant and impermeable protective clothing options are available in the market place for healthcare workers. These include isolation gowns, surgical gowns, and coveralls. When selecting the most appropriate protective clothing, employers should consider all of the available information on recommended protective clothing, including the potential limitations.

Employers should consult protective clothing manufacturers as needed in regards to availability and practicality for their facilities. A key step in this process is to understand the relevant standards and test methods.

Protective clothing for radiation

Protection against radiation is a complicated task. Scientists differentiate ionizing radiation hazards from the radioactive, contaminated particle, or liquid hazards.

Safety garments are designed to minimize the penetration of radioactive airborne particles and prevent their contact with your skin. Protective suits keep radioactive isotopes out of your body, but cannot shield you against the ionizing radiation.

The United States Department of Homeland Security defines protective clothing for radiation as “an overall garment worn to protect people from hazardous materials or substances, including chemicals, biological agents, or radioactive materials.” – Protective clothing for radiation

Protective clothing for hazardous materials

The purpose of clothing for hazardous materials and equipment is to shield or isolate individuals from the chemical, physical, and biological hazards that may be encountered during hazardous materials operations. During chemical operations, it is not always apparent when exposure occurs. Many chemicals pose invisible hazards and offer no warning properties.

It is important that protective clothing users realize that no single combination of protective equipment and clothing is capable of protecting you against all hazards. Thus protective clothing should be used in conjunction with other protective methods. For example, engineering or administrative controls to limit chemical contact with personnel should always be considered as an alternative measure for preventing chemical exposure.

Protective clothing for hospitals

Personal protective equipment (PPE) refers to protective clothing, helmets, gloves, face shields, goggles, facemasks, and/or respirators or other equipment designed to protect the wearer from injury or the spread of infection or illness.

PPE is commonly used in health care settings such as hospitals, doctor’s offices, and clinical labs. When used properly, PPE acts as a barrier between infectious materials such as viral and bacterial contaminants and your skin, mouth, nose, or eyes (mucous membranes). The barrier has the potential to block the transmission of contaminants from blood, body fluids, or respiratory secretions.

PPE may also protect patients who are at high risk for contracting infections through a surgical procedure or who have a medical condition, such as, an immunodeficiency, from being exposed to substances or potentially infectious material brought in by visitors and healthcare workers.

Protective clothing for cleaning

A basic level of personal protective equipment (PPE) should be used by all front-line custodial workers, no matter what job they are performing or what chemical they are using. Protecting workers from cleaning chemicals and restroom germs will keep them efficient and safe.

“Chemicals and PPE help you get the job done faster — people are able to pay better attention to what they’re doing if they can do it efficiently”.

All custodial employees should be provided gloves, goggles, and protective uniform specifications such as long sleeves and rubber-soled safety shoes or shoe covers.

“OSHA regulations and your facility safety guidelines should determine the minimum PPE an employee should use for specific tasks”

“If a restroom has as biohazard inside, then additional PPE would be required, such as a dust mask and a biohazard suit. Most companies have a written safety plan and written task procedures for employees to follow when performing assigned duties.”

Flame resistant clothing

Flame-Resistant clothing is made from a material that is inherently resistant to flames and embers. Meaning that the threads and fibers will naturally self-extinguish. Flame-Retardant clothing, on the other hand, is made from materials that have been chemically treated to achieve the same self-extinguishing properties.

Importance of protective clothing

Safety clothing is important in the workplace as it protects users against any health and safety risks at work. Also called PPE (Personal Protective Equipment), it lessens the likelihood of injury, illness, and legal issues, and ensures a safe, happy working environment for all.

The importance of safety clothing cannot be stressed enough. With most industries, these days having a strong focus on health and safety, being geared up for the job fulfills your duty as an employer and ensures your workforce stays protected and free from injury.

Usually, the garments protect delicate areas, such as helmets for the head and sturdy boots for the feet. They also protect features such as sight and hearing, and also the mouth and nose to prevent inhalation of dangerous substances.

Types of disposable coveralls

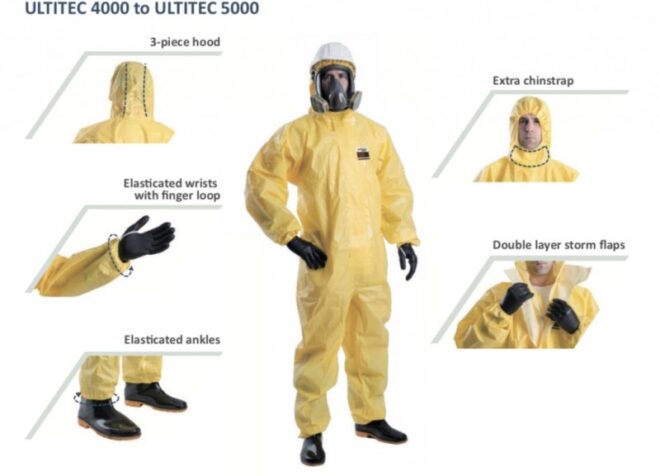

Many workplaces and workplace health and safety guidelines mandate that staff wear PPE including disposable protective coveralls for certain work processes. These both handling asbestos and hazardous processes like working with chemicals, paint spraying, woodwork, chemical manufacturing, environmental remediation, cleaning, and handling fiberglass.

Standards Approved protective coveralls are generally specified with a ‘Type’. This Type illustrates what they protect against. It relates back to tests carried out in accordance with a host of International or EN Standards. In brief, these standards cover a wide range of individual performance tests that check for resistance against:

- Abrasion and cracking

- Tensile strength and tear resistance

- Resistance to punctures

- Resistance to chemical permeation

- Liquid repellence

- Resistance to spray and aerosols

- Resistance to ignition

- Type 1 – Gas tight

- Type 2 – Non-Gas tight

- Type 3 – Liquid tight

- Type 4 – Spray tight

- Type 5 – Protects against airborne particles

- Type 6 – Protects against liquid chemical splash

When used properly and with other infection control practices such as hand-washing, using alcohol-based hand sanitizers, and covering coughs and sneezes, it minimizes the spread of infection from one person to another. Effective use of PPE includes properly removing and disposing of contaminated PPE to prevent exposing both the wearer and other people to infection.

All personal protective equipment that is intended for use as a medical device must follow The FDA’s regulations and should meet applicable voluntary consensus standards for protection. This includes surgical masks, N95 respirators, medical gloves, and gowns. The consensus standards and the FDA’s requirements vary depending on the specific type of PPE. When these standards and regulations are followed, they provide reasonable assurance that the device is safe and effective.

Disposable Protective Clothing

Protective clothing is essential to prevent the spray, mist, or dust of pesticides from contacting your skin during an application.

Industrial Digital Thermometer

They are generally more durable than laboratory thermometers. Operation depends on the type of temperature sensor you use.

Digital Infrared Thermometer

The main use of the infrared thermometer is to read a particular spot on a surface of the wall, ventilation, automobile, or food item.

Best Construction Clothing Brands

When work becomes monotonous, construction equipment brands create and design casual clothing for fans of these brands.