EPCM stands for Engineering, Procurement, Construction Management. This type of contract is different from an EPC Contract in that the Contractor is not directly involved in the construction but is responsible for administering the Construction Contracts.

EPC and EPCM services

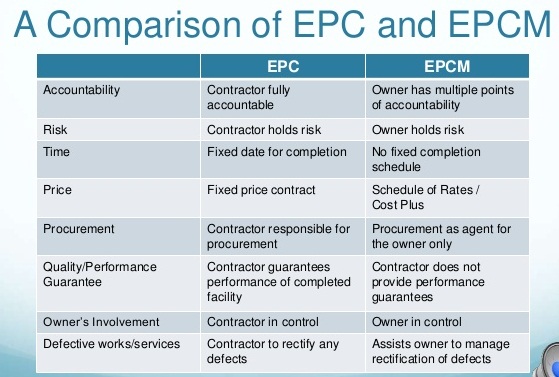

Although the engineering, procurement, and construction (EPC) contract and the engineering, procurement, and construction management (EPCM) contract have been present in the construction sector for many years, there remains confusion as to the fundamental differences between these contracts, the role each party is required to play, and when to use one contract over the other.

The fundamental difference is the role of the EPC or EPCM contractor. In an EPC contract, the EPC contractor develops the project from commencement to final completion.

The owner or principal of the EPC project provides the EPC contractor with a detailed design including technical and functional specifications, in order for the EPC contractor to build and deliver the project to the “turn of the key”, within a specified time period.

EPCM Contract

This is why EPC contracts are often referred to as “turnkey” projects. The scope of work should be clearly defined in the contract documents; therefore, amendments to the scope of work should not be a common feature in EPC contracts.

For this reason, an EPC contract is often a fixed price contract or an all-encompassing lump sum contract. Any shortfall of costs is a risk that rests with the EPC contractor, making cost control their number one priority.

EPCM services

A further identifying feature of the EPC contract is that the EPC contractor enters into separate agreements with the contractors, vendors, sub-contractors, sub-vendors and so on.

This is advantageous to the owner or principal of the project, as they will look to the EPC contractor to take full responsibility for the project and, in the event of a dispute between the EPC contractor and any party to the sub-agreements, to resolve the dispute without the owner or principal being required to be a party to the dispute.

The EPC contractor will, in most cases, have a right of recourse against a party to a sub-agreement who was responsible for causing the loss or damage. The EPC contractor must ensure that its contracts mirror those that it has with the owner of the principal.

EPC company means

In contrast to the EPC model, the EPCM contractor is not directly involved in the building and construction of the project, but is rather responsible for the detailed design and overall management of the project, on behalf of the owner or principal.

While an EPC contract takes the form of a design and construction contract, the EPCM model can be regarded as a professional services contract.

The EPCM contractor has a duty to ensure that the engineering and design of the project are in compliance with the project’s technical and functional specifications.

Supervising, management and co-ordinating construction interface in accordance with a detailed schedule is the key responsibility of the EPCM contractor.

EPCM contractor

The EPCM contractor is responsible for establishing contractual arrangements on behalf of the owner or principal with other contractors, vendors, sub-contractors and sub-vendors, through a tender process.

The EPCM contractor is contracted by the owner or principal for the construction management role, while the owner or principal is bound to various contractual relationships for construction-related works.

From an owner or principal’s perspective, there lies a disadvantage in being bound to various contractual relationships in the event of a dispute. Unlike the EPC model, the owner or principal will more often than not find itself involved in a dispute with one or more of the other parties relating to the construction of the project, to whom the EPCM contractor must offer assistance.

EPCM projects

In most instances, the EPCM model is structured on the basis of a cost-reimbursable fee structure or a unit rate fee structure.

The former allows the EPCM contractor to be paid an upfront sum of money with additional fixed monthly payments, while the latter allows for an upfront sum of money with further payments to be made on completion of specified phases within the construction process.

Both the EPC and EPCM contracts can be highly beneficial to a project. Choosing the incorrect form of contract can have a major effect on the cost and risk associated with the project.

The contract you choose to utilize requires a clear understanding of the objectives, scope of work, the role of each party and the contract structure as a whole.

Difference between EPC and EPCM

Comparing EPC and EPCM contracting

EPCM contracting contrasts with EPC (engineer, procure and construct) contracting because, in EPC contracting, the EPC contractor is responsible for the construction and it, rather than the employer, enters into direct contracts with the construction contractors.

EPC contracting appears to be more common that EPCM contracting. This is because employers often regard EPC contracting as favoring their interests over those of the contractor.

There are several reasons for this, including:

- Cost certainty. EPC contracting shifts risk away from the employer and towards the EPC contractor, in theory giving the employer greater cost certainty than other forms of procurement. An EPC contract typically prevents the contractor from increasing the agreed price except in very limited circumstances.

- Single point of responsibility. The EPC contractor is responsible to the employer for the entire project, so there is no confusion about who the employer should pursue in the event of a defect or other problem.

- Turnkey nature. An EPC contract is a turnkey, meaning that, on completion, the employer will simply be able to “turn the key” and operate the finished facility. This is particularly attractive to an employer with little experience of running a construction project or with inadequate resources to oversee such a project.

EPCM contract template

Equally, there are several reasons why an employer may prefer EPCM contracting over EPC contracting:

Lower cost

- EPCM contracting offers potential savings on project costs.

- EPC contractors usually charge more because of the extra risk they take on from the employer.

- In EPCM contracting more risk stays with the employer, so prices should be lower.

- In addition, the employer has the benefit of negotiating each construction and supply contract itself, rather than relying on an EPC contractor to get the best price.

Construction flexibility

- Compared with EPC contracting, the employer has greater freedom to change the project during the works.

- Under an EPC contract, variations to the agreed specification can easily lead to large increases in project cost.

- In EPCM contracting this may be avoided because the employer can negotiate directly with contractors and suppliers.

Speed construction

- Compared with EPC contracting, the employer may be able to complete the project more quickly.

- EPCM contracting allows the employer to engage the necessary contractors to begin work, without necessarily finalizing the detail of the project right away or entering into contracts for works or equipment that will be needed later.

Funding companies

- EPC contracting usually requires the contractor to have all its funding arranged at the outset of the project, in order to secure a letter of credit in favor of the EPC contractor.

- In contrast, EPCM contracting allows greater flexibility, so the employer does not necessarily need to have all funding in place before works begin.

Quality construction

- EPCM contracting may offer a higher quality result than EPC contracting.

- This is because EPC contracting (like design and build construction) leaves the EPC contractor to decide how it will meet the employer’s requirements for the agreed price.

- It is in the EPC contractor’s interest to meet the employer’s requirements at the minimum cost, thereby maximizing its own profit.

- In contrast, EPCM contracting allows the employer to take an active role throughout the project, advised by the EPCM contractor.

- In theory, this allows the employer to control the quality of the project.

- Even if there is no measurable qualitative advantage to EPCM contracting, the employer often feels a greater sense of satisfaction with the completed project because it has had “ownership” of the project throughout its course.

Overall, the employer’s role in negotiating contracts and funding burden it with greater responsibility in an EPCM project. However, this is tempered by the fact that the EPCM contractor is available to advise the employer throughout the project, together with the increased control the employer has over its project.

EPCM environment

Disadvantages of EPCM contracting

The advantages of EPCM contracting are balanced by some significant drawbacks. In general, these can be summarised as a transfer of risk and responsibility to the employer.

Two of these drawbacks are key to understanding EPCM contracting:

No single point of responsibility

- EPCM contracting has no single point of responsibility, so in the event of a defect in construction, the employer may have to pursue several contractors and suppliers to recover its losses.

- Whether these parties are jointly and severally liable will depend on the precise wording of their contracts and the jurisdiction governing them.

Management time and expense

- Even with the EPCM contractor’s assistance, an EPCM project requires the employer to commit significant resources to it.

- The employer should consider whether those resources could be better invested elsewhere in its business.

EPCM engineering

One other disadvantage of EPCM contracting is the absence, at the moment, of any standard form of an EPCM contract.

Many engineering contracts, even those that are bespoke, take a standard form contract as their starting point. For example, many bespoke EPC contracts are based on the FIDIC Silver Book.

The absence of a standard form deprives the parties of a point of reference as to the “normal” commercial and legal position, as well as increasing the legal costs of the project.

In any case, the employer is likely to incur higher legal costs on an EPCM project, simply because it has to negotiate multiple contracts, rather than a single EPC contract.

While this may be a minor inconvenience for a large and experienced employer, it is a significant drawback for a smaller and less experienced employer.

EPCM resource management solutions

A final word of caution

Parties should remember that procurement terminology is not subject to universal rules about its meaning (except, arguably, in the field of public procurement). One party’s understanding of EPCM contracting may differ from another’s and, in any case, employers often tailor a procurement mechanism to suit the needs of a particular project. Terms such as EPCM and EPC are a useful shorthand, but parties should clarify their precise meaning for each particular project.

What is EPCM contract

The EPCM contractor is not directly involved in the building and construction of the project, but is rather responsible for the detailed design and overall management of the project, on behalf of the owner or principal. While an EPC contract takes the form of a design and construction contract, the EPCM model can be regarded as a professional services contract.

What is an EPCM company?

EPCM stands for Engineering, Procurement, Construction Management. This type of contract is different from an EPC Contract in that the Contractor is not directly involved in the construction but is responsible for administering the Construction Contracts.

The fundamental difference is the role of the EPC or EPCM contractor. In an EPC contract, the EPC contractor develops the project from commencement to final completion. This is why EPC contracts are often referred to as “turnkey” projects. For this reason, an EPC contract is often a fixed price contract or an all-encompassing lump sum contract. Any shortfall of costs is a risk that rests with the EPC contractor, making cost control their number one priority.

In contrast to the EPC model, the EPCM contractor is not directly involved in the building and construction of the project, but is rather responsible for the detailed design and overall management of the project, on behalf of the owner or principal.

Whereas, Turnkey is a contract comprising Engineering, Procurement, Construction, and commissioning; It is such a contract that under which a contractor agrees to complete full designing, constructing and equip a manufacturing/ business/ service facility and turn the project over to the Employer/Owner when it is ready.

The engineering and construction contractor will carry out the detailed engineering design of the project, procure all the equipment and materials necessary, and then construct to deliver a functioning facility or asset to their clients. Companies that deliver EPC Projects are commonly referred to as EPC Contractors.

PMC stands for Project Management Consultant or Project Management Contract. Under a project management contract, an engineering contractor will overlook the EPC Contractor’s work to ensure compliance with the client’s scope of works.

The most read

EPC Construction Company

What is EPC’s company? EPC services company, EPC construction company, EPCM Contract, Top EPC Companies in the USA

Top EPC Companies

EPC services company, EPC oil & gas multinational company, EPC company means, what is EPC company.