Mobile Crane Hand Signals: Communication between the crane operator and the signal person shall be maintained continuously during all crane movements. If at any time communication is disrupted, the operator shall stop all crane movements until communication is restored and a proper signal is given and understood.

Printable mobile crane hand signals

Mobile Crane Hand Signals charts

Standard crane hand signals

Crane operator hand signals chart:

Mobile Crane Hand Signals: At Crane and machinery, we realize that not everyone at the job sites we go to is fully trained in mobile crane operation and safety.

For this reason, all mobile crane operators must have experience and education on all aspects of material handling and mobile crane procedures, including all common manual signals for mobile crane operators.

If the operator has any concerns regarding the requested movement of the crane or needs to communicate with the signal person, the operator shall stop all crane movement.

Crane movement shall not resume until the operator and the signal person agree on the issue at hand has been resolved. If it is desired to give instructions to the operator, other than those provided by the established signal

Crane signalman

On construction sites, one of the most important jobs is that of the signal person. Sometimes known as the signalman, this individual is responsible for signaling the crane and giving the operator orders that pertain to the lift. In order to accurately and safely direct crane operators, the signal person must know and understand the relevant signals used in regulations.

Additionally, just like the machine operator, they must understand the operations and limitations of the equipment they are directing, including the crane dynamics involved in swinging, raising, lowering loads, stopping loads, and boom deflection.

Audible crane signals

While radio and other means of electronic communication with an operator are acceptable, using hand signals are the most effective and reliable way of communication.

Electronic methods communication could potentially fail to work, leaving the operator and the on-ground director without means to understand one another or give direction. When using radios or other methods, it must be through a dedicated channel so there is no interference.

Mobile crane hand signal chart

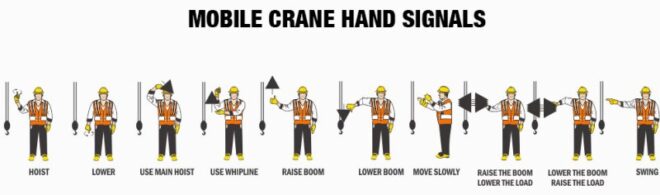

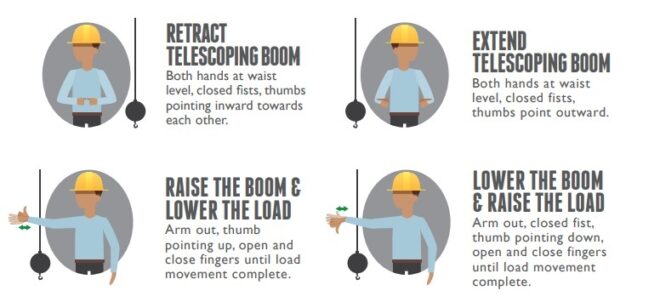

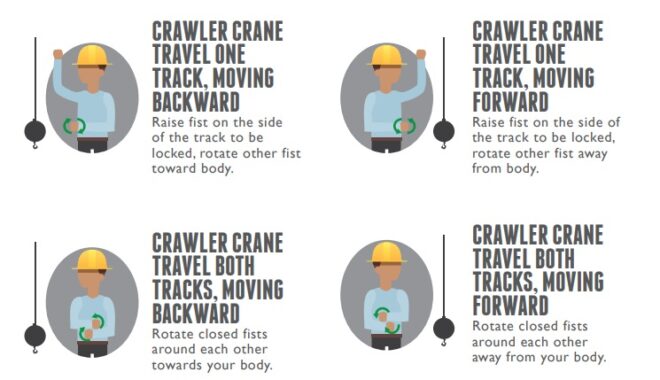

Successful communication between the signalman and the operator relies on both individuals fully understanding all hand signals used. Find below examples of standard hand signals used to control mobile crane operations

Standard crane signals

- Communication between the crane operator and the signal person shall be maintained continuously during all crane movements. If at any time communication is disrupted, the operator shall stop all crane movements until communication is restored and a proper signal is given and understood.

- If the operator has any concerns regarding the requested movement of the crane or needs to communicate with the signal person, the operator shall stop all crane movement. Crane movement shall not resume until the operator and the signal person agree on the issue at hand has been resolved.

- If it is desired to give instructions to the operator, other than those provided by the established signal system, the crane movements shall be stopped.

Standard hand signals for crane operators

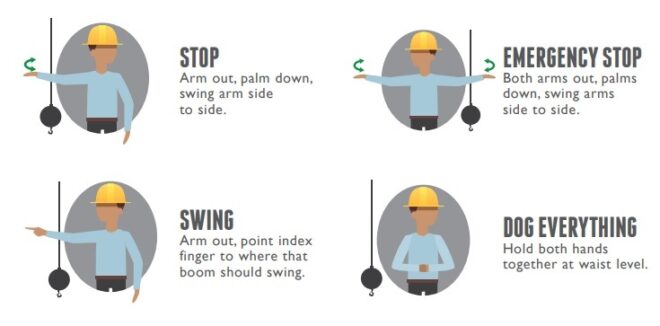

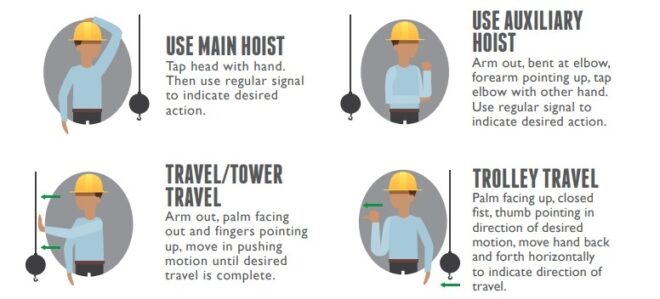

In some circumstances, radio communication between a crew and a crane operator is not an option. It is important to know the common signals for crane operation to ensure that it is still possible to properly operate the mobile crane. Some of the basic hand signals to use when working with a crane operator include:

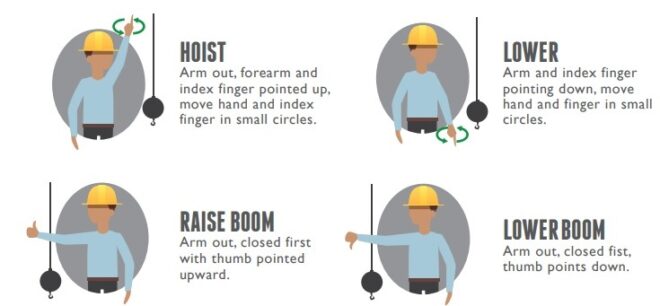

- LOWER THE CRANE’S LOAD: If the load needs to be lowered in place, point your forefinger downward with your arm extended toward the ground and move your hand in small circles.

- RAISE THE BOOM: When the boom needs to be raised, extend your arm horizontally from your body and give the thumbs-up sign.

- LOWER THE BOOM: In a similar fashion to the signal for raising the boom, extend your arm horizontally and give the thumbs-down signal to lower the boom.

- SWING THE BOOM: If the load needs to move side to side while remaining at its current height, extend your arm outward horizontally and point in the direction that the boom needs to swing.

- EXTEND THE BOOM: If the load needs to move farther away from the crane, lower your elbows to your waist and extend your forearms at a right angle so that your hands extend forward. Point both thumbs outwards, away from your body. This will indicate to the operator to extend the boom.

- PROCEED SLOWLY: If any action needs to be done slowly and carefully, place your hand above the hand that is performing the action signal.

Printable mobile crane hand signals

Using standard hand signals is the most widely used manner of signaling a crane operator. A hand signal chart can usually be found on the side of the crane or it should be conspicuously posted in the vicinity of where hoisting operations are being conducted.

New signals can be given to the crane operator but they must be agreed upon beforehand by the crane operator(s), signalperson(s) and lift director (if one is used).

Crane signal person training

A signal person must be provided in each of the following situations:

- The point of operation, meaning the load travel or the area near or at load placement, is not in full view of the operator.

- When the equipment is traveling, the view in the direction of travel is obstructed.

- Due to site-specific safety concerns, either the operator or the person handling the load determines that it is necessary.

Crane operator hand signals

Types of signals. Signals to operators must be by hand, voice, audible, or new signals.

Crane hand signals

- When using hand signals, the Standard Method must be used. Exception: Where use of the Standard Method for hand signals is infeasible, or where an operation or use of an attachment is not covered in the Standard Method, non-standard hand signals may be used in accordance with paragraph (2) of this section.

- Non-standard hand signals. When using nonstandard hand signals, the signal person, operator, and lift director (where there is one) must contact each other prior to the operation and agree on the non-standard hand signals that will be used.

New signals

Signals other than the hand, voice, or audible signals may be used where the employer demonstrates that:

- The new signals provide at least equally effective communication as voice, audible, or Standard Method hand signals, or

- The new signals comply with a national consensus standard that provides at least equally effective communication as voice, audible, or Standard Method hand signals.

Suitability

The signals used (hand, voice, audible, or new), and means of transmitting the signals to the operator (such as a direct line of sight, video, radio, etc.), must be appropriate for the site conditions.

Crane operations hand signals

During operations requiring signals, the ability to transmit signals between the operator and signal person must be maintained. If that ability is interrupted at any time, the operator must safely stop operations requiring signals until it is reestablished and a proper signal is given and understood.

Verbal crane signals

If the operator becomes aware of a safety problem and needs to communicate with the signal person, the operator must safely stop operations. Operations must not resume until the operator and signal person agree that the problem has been resolved.

Mobile Crane Hand Signals

Using standard hand signals is the most widely used manner of signaling a crane operator. A hand signal chart can usually be found on the side of the crane or it should be conspicuously posted in the vicinity of where hoisting operations are being conducted.

During crane operation, only one person can give signals, unless it’s for an emergency stop – then anyone on the Jobsite can give the signal. Once the qualified signal person is identified, the signal person and the crane operator must identify each other prior to giving any signals.

The most read

Mobile Crane Safety

This article focuses on hazards, including where they might be found in different workplaces. We also provide you with a range of further resources to make your risk assessment process as smooth as possible.

Slewing Mobile Crane

Slewing mobile cranes incorporate a boom or jib that can be rotated. It excludes front-end loader, back-hoe, excavator or other earth moving equipment when configured for crane operation.