Mobile crane load chart: Simply put, the only way to know if the load you are lifting with a mobile crane is within the limitations of the crane is to relate the lift to the manufacturer’s load chart and notes.

Persons who are not crane-operators regularly have questions regarding lifting safety. The purpose of this Tech Tip is to help those less familiar with crane load charts better understand the questions to ask and the information that must be followed.

Mobile crane specification

An experienced crane operator enters the cab of an unfamiliar crane expecting to find certain information on the load chart. Just as you may expect to find certain information when you enter an unfamiliar automobile. You locate the speedometer and fuel gauge, then locate windshield wiper, outside mirror, and seat adjustment controls.

You do this because you know these controls must exist to operate safely. Similarly, certain information will always be located within a crane’s load rating chart and notes. You just have to know what you’re looking for.

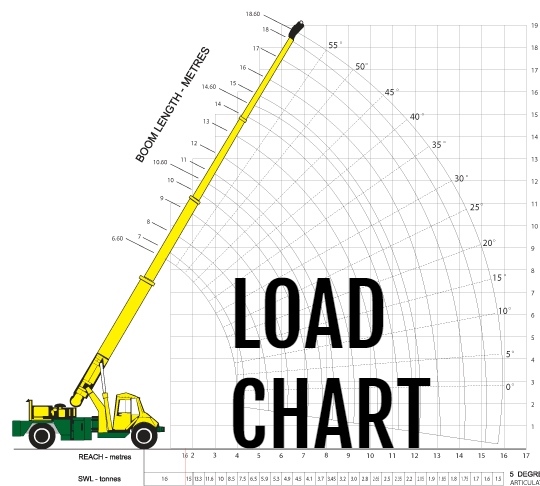

Crane load chart

The crane load chart in the mobile crane industry is long past the days of a single page load chart. Load charts have become increasingly complex. There is specific information you must obtain prior to attempting to lift a load.

- How is the crane configured? Are the outriggers fully extended and set, partially extended and set, or will the lift be made on rubber tires?

- How much counterweight is installed on the crane?

- What are the boom and jib/extension configurations? If the lift will be made with an extension or jib you must locate the load chart that provides ratings for these accessory devices.

Mobile crane lifting capacity

Over what operating areas will the load be handled? Working Area charts define specific areas of the crane that relate to loading ratings.

Areas such as Over the Side, Over the Rear, Over the Front, and 360-degree Rotation lead you to specific load charts. Make certain you know the area where the load will be lifted from, the area the load will pass through, and the area the load will be placed.

Base lifting capacities on the area with the least load rating according to the working area chart. The combined information to this point will lead you to one or more pages within a load chart.

How to calculate crane load capacity?

Does the crane have sufficient load hoist reeving? Reeving charts indicate the type of wire rope and the number of parts of wire rope required to lift loads. A reeving chart which indicates 28,000 lbs. capacity for a two-part reeving will require more reeving prior to making a lift that exceeds 28,000 lbs.

To determine how much load the crane can safely handle you must also know the length of the boom (hydraulic cranes show boom lengths in a row at the top of the load chart), and the load radius of the suspended load (hydraulic cranes show radius in a column on the left side of the load chart).

When boom length and/or radius is between the values printed on the load chart you must select the boom length and/or radii with the least load rating.

Keep in mind that a shorter boom length may have a lesser rating. You cannot assume that taking load values from the next longer boom length is safe.

Crane capacity chart

Equally important to the load ratings shown on the chart are the load chart notes. Load chart notes provide critical information relating to the operation, set up, configuration, and restrictions.

Finally, you must account for all accessory weights. Items such as load blocks, extensions, jibs, and rigging must be added to the weight of the load to determine the total load imposed on the crane.

Don’t hesitate to ask a crane operator for clarification. And, don’t think twice about challenging what you are told. Load charts may have become more complex, but the key information provided has not changed significantly.

Knowing what to look for is a good start to a safer job site. Safety is a team effort that requires both the operator and management working with the same safety objectives. Don’t compromise your job site safety.

Mobile crane load chart calculations

Mobile crane stability:

We’ve looked at how gravity, balance, and leverage work together to keep a crane stable, how the crane is made, what the tipping point is, and what the standards and OSHA say. Now let’s apply what we’ve learned.

We cannot stress the importance enough of taking the time and making the effort to ensure proper setup, knowing your load weight, and having an educated operator–it just might save you a costly mistake.

Mobile crane lifting

Lifting on Rubber: Crane manufacturers that allow “on rubber” lifts will provide a load rating chart specifically for this configuration.

Mobile crane outriggers

Over the Side: Not only are fully set outriggers recommended for the full capacity of the load chart, lifting over the side is the least stable location for most cranes. For this reason, try to position the crane to make the initial lift in the least stable location (such as over the side), and then swing to a more stable location (such as over the end). This may help prevent an accidental overload of the crane during the lift. In other words, any miscalculation of the load weight can be noticed right away.

Mobile crane boom extension

Over the Front: When the boom is positioned over the front of a crane on outriggers, the tipping axis is the forward set of outriggers. Crane manufacturer’s that allow “over the front” lifts will provide a load rating chart specifically for this configuration.

Crane boom angle

Over the Rear: When the boom is positioned over the rear of a crane, the tipping axis is the rear set of outriggers. While this is usually where the most capacity is provided, you must still follow the load chart and know your load weight for your lift to ensure the crane will remain stable and upright.

Crane boom length

Boom Length: Just because a crane has a long reach, doesn’t mean you need to use all of it. Many times tipping is a result of the boom being extended beyond the necessary length.

Mobile crane safety tips

Hopefully, by now, we can all agree that the loss of stability resulting in a tipping incident or accident shouldn’t be a common occurrence. They are costly and can be avoided. Remember the following key points:

- Make sure the operator is a qualified mobile crane operator with the education, knowledge, and experience to operate the machine and make the lift.

- There are many crane designs, read the crane manufacturer’s operation manual to make certain the operator fully understands the operating quadrants, superstructure positions and operating characteristics of the crane.

- Make sure the operator fully understands the load capacity chart for the crane they are operating.

- Make sure the operator fully understands how to use the crane’s load weighing device (LMI, RCI, RCL, etc.).

- NEVER lift loads where the load chart does not provide ratings.

- NEVER lift more weight than what’s posted in the load chart.

- Outriggers are to be fully extended and set at all times when practical.

- Never allow the operator to “lift by the seat of their pants” if they can start to feel the crane tipping, then it is already too late, the crane has been overloaded.

How to read crane load chart?

The book, “Mobile Crane Support Handbook” is a comprehensive reference that is focused exclusively on the design and engineering of supports for mobile crane installations.

Written by one of the leading lifting specialist engineers, this book addresses the full range of subjects needed for the engineering of mobile crane support in construction job site situations.

Topics covered include support reactions from crawler and outrigger-supported cranes, soil bearing capacity, analysis of subsurface structures, the strength of crane mats, practical design methods, and industry standards and regulations.

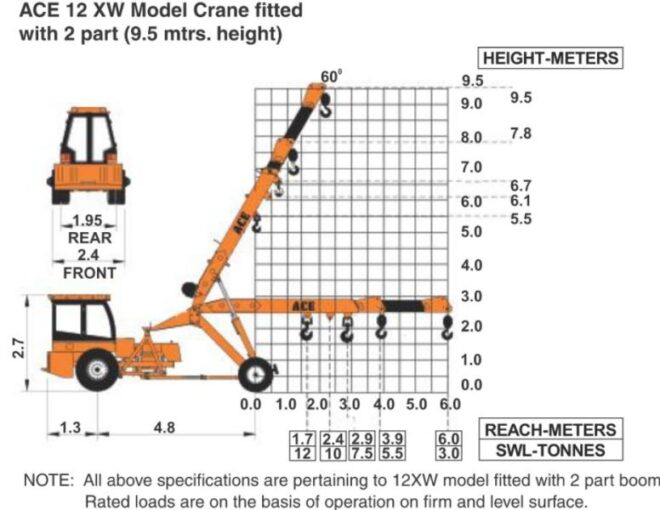

Each crane has a load chart that, in short, specifies the crane’s capabilities—detailing its features and how its lift capacity varies when considering distance and angle. Just like the old saying ‘if you fail to plan, you plan to fail,’ failing to consult a crane load chart before renting or employing a crane for a specific job could leave you with too much or too little capacity for your job.

Virtually all construction projects require the lifting, hauling or transportation of heavy materials ‘ which is why cranes play a gigantic role in the development of your project.

Deciding which crane is right for your objectives can be an overwhelming task, as the range of options available is limitless! There is an enormous variety of cranes ‘ each designed for a specific function or use.

The most read

Crane lifting capacity calculation

The operations planning team uses load charts and manual calculations to determine if the operation can be executed.

Mobile crane lifting capacity

The nominal loads shown in the lift chart are for each machine as originally manufactured and equipment.