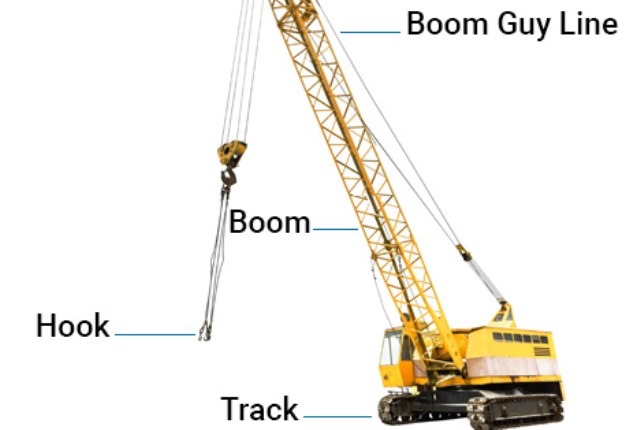

The parts of an industrial or construction telescopic mobile crane have the following main components:

- Chassis camion

- superstructure

- turn system

- winch

- counterweight

- stabilizers

Telescopic mobile crane

In the case of the self-propelled telescopic crane, the assemblies can be divided into two distinct parts: supporting chassis and superstructure.

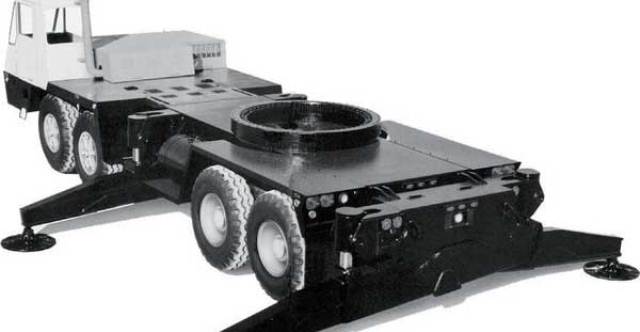

The chassis is a metallic structure on which, in addition to the propulsion and steering systems, the remaining components are fixed.

The superstructure is constituted by a base platform on an orientation crown that joins the chassis and allows 360º rotation, which supports the telescopic boom, lifting equipment, control cabin, and counterweight if necessary.

Crane chassis

Crane carrier

crane manufacturers also manufacture the frame, box-shaped, with the optimum weight, torsion-proof. The motor supplies the necessary energy for its displacement, as well as for all the handling maneuvers of the crane’s own loads.

Transmission, shaft, and reducers

They are the generally axially symmetrical elements responsible for supporting the rotating parts.

Chassis – structure

It is the metallic framework responsible for supporting the machinery.

Crane stabilizer

Support elements, which transmit the efforts to the ground. They also allow to increase the surface of the lift polygon and improve the distribution of loads on the ground.

Engine crane

It is the mechanical system that allows equipping the chassis – structure assembly with enough movement to move.

Crane shaft

They are the generally axially symmetrical elements responsible for supporting the rotating parts.

Crane Suspension

Set of elements that cushion the irregularities of the road.

Crane Brake

It is the device used to stop or slow down the movement of the crane. Study of telescopic boom for self-propelled crane –

Crane Superstructure

Base platform

It is responsible for supporting the telescopic boom, lifting equipment, control cabin, and counterweights.

Orientation crown

Allows the superstructure to perform a 360º turn.

Lifting equipment

Motor crane: Mechanical system that allows operating the necessary elements to carry out the lifting of the load.

Winch: It is the mechanical device designed to lift and move the loads.

Cab Cranes

It is a small structure designed for the operator to perform the necessary actions with greater safety and comfort; It has all the necessary controls to perform the operations.

Telescopic boom

The telescopic boom formed by several sections that allow varying the length through a telescopic procedure.

Security devices

Integrated systems in the crane so that you can perform an action as controlled as possible and try to avoid possible contingencies.

mobile crane Counterweight

They are weights arranged in such a way that they allow to balance the forces or torque produced.

Crane rotating mechanism

Crane rotation system

It is the system that allows giving the telescopic boom a turning movement to allow to choose the desired orientation of the pen.

This will allow the crane to rotate 360º with a number of unlimited turns. It consists of two parts: the bearing, necessary to withstand axial, radial and overturning forces, in addition to allowing smooth rotation of the crane and the motor that allows providing the necessary torque to allow rotation.

Bearing for cranes

The rotation of the crane is carried out by means of a large ROTHE ERDE bearing. This bearing is a machine element that forms a complete unit, provided for the simultaneous transmission of axial and radial forces and the resulting tipping torques, thus performing a double function.

On the one hand, it has to allow a smooth turn of the superstructure to conveniently position the load and on the other hand, it has to support all the weight coming from the elements that make up the superstructure.

The bearing has an outer crown that meshes with the pinion of attack located in the rotating part. Fixed by screws, the outer toothed ring sits on the fixed part of the crane and is secured by 60 M24 screws.

Once the ring gear has been assembled, a plate fixed by screws to the turning bearing will be placed to weld the rotation structure in this way, allowing the transmission of the movement to the moving part.

Crane motor

For the choice of the motor type, a three-phase asynchronous motor has been chosen. This choice is due to the fact that this type of motor is the most used in the industry, due to its robustness and simplicity of operation.

It is responsible for transmitting the necessary effort, first to accelerate the system by overcoming the inertia of the elements and then to keep it moving by overcoming the frictional force to which the bearing type is subjected.

It is anchored to the movable structure, with the flange that incorporates, in such a way that the pinion of attack is below this structure meshing with the toothed crown.

Winch crane

It is a mechanical system that will allow handling and lifting of loads. It will be driven by a drum where a cable with a certain length will be wound, which will circulate through a system of pulleys to reduce the tension, reaching a hook, which will manipulate the load.

Drum for crane

This element is located in the back of the crane, in the structure of rotation. Its function is to store and pull the cable to produce the lifting movement of the load in addition to loose cable in cases where more length is needed.

Crane Cable

The component that will transmit the force of the drum to the hook, causing its movement. In its dimensioning, the FEM standard has been used where it marks a series of recommendations for the correct selection of the cable that guarantees a correct operation.

It should be noted that for design reasons it has been chosen to use two cables during the useful life of the crane studied in the present project.

Crane Pulley

The purpose of a pulley is to change the direction of the cable and decrease the tension of the cable.

The diameter of the pulley depends on the minimum diameter that the cable must have, as well as on the type of group in which the lifting mechanism is classified and also according to the assembly it has.

In the case of the present project, the pulley is incorporated with the appropriate bearings. The present crane studied has 4 cable pulleys that together with the pulleys that contain the chosen hook can form a hoist (A hoist is a combination of fixed and mobile pulleys which are covered by a single cable that has one of its ends anchored at a fixed point, this system allows to obtain a mechanical gain), depending on the cable re-routing, so as to reduce the effort to be made by the drum.

Hook Crane

The hook assembly is constituted, first, by the hook itself and by the set of pulleys that require the type of hook.

The hook rises and descends by means of the cable of elevation that happens through the pulleys, depending on the type of load more or fewer cable reenvíos will be needed creating a hoist.

The hook can be balanced to facilitate loading and unloading operations. In addition, the lower support is mounted on an axial ball bearing that allows the hook to turn on the vertical axis. These elements are assembled in a structure formed by plates and tubes that allow rigidity to the whole.

Crane Counterweight

The function of the counterweight is simply to reduce the tipping torque of the crane. The counterweight will not be calculated or manufactured in this project but will be taken into account to perform the stability calculations.

Mobile crane stability

The stabilizers will be used to ensure stability in the crane and prevent it from tipping over, therefore the installation of stabilizers will be necessary.

It must be taken into account that different situations will have to be calculated depending on the direction of the telescopic boom since it does not have the same impact on stability if the load is in the front, rear or side of the crane.

The calculation has been made for the critical position whose angle of inclination is 80º, length 20m and a maximum load of 452kN.

What is a mobile crane used for?

A crane is a type of machine, generally equipped with a hoist rope, wire ropes or chains, and sheaves, that can be used both to lift and lower materials and to move them horizontally. It is mainly used for lifting heavy things and transporting them to other places.

Hydraulic cranes work on the concept of transmitting forces from one point to another through a fluid and only due to this they are able to lift the heavy loads. In essence, a hydraulic crane works on optimizing the strength that is produced by the liquid under pressure.

Through a combination of simple machines, mobile cranes are able to gain mechanical advantage to lift heavy objects. The mast (the tall vertical part of a crane) is supported by a large, heavy base, which helps offset the weight the crane holds at higher heights.

The maximum load that the crane can lift is 18 metric tons, but the crane cannot lift that much weight if the load is positioned at the end of the jib. The closer the load is positioned to the mast, the more weight the crane can lift safely. The 300 tonne-meter rating tells you the relationship.

The Liebherr LTM 11200-9.1, built by the German company Liebherr Group, is the most powerful mobile crane ever built. It also has the longest telescopic boom in the world, which extends fully to 100 meters. It’s set on a double cab truck and can lift 1200 metric tons – that’s nearly 700 automobiles.

Costain has used the UK’s largest mobile crane to install the main deck girders for the Clydach River Bridge. The bridge, located in Saleyard, is part of the Heads of the Valleys project to create a dual carriageway on the A465.

The most read

Telescoping Boom Lift

Traditionally, the telescoping system consisted of as many extension cylinders as the displaceable sections had the boom of the telescopic crane. This gave the crane great flexibility of movements with the counterpart of excessively increasing the weight of the pen itself.

Telescopic Mobile Crane

Heavy cranes, such as telescopic cranes, can be mounted on top of a truck and then driven to those places where goods and loads need to be moved.