Warehouse layout design: With the continued growth and domination of e-commerce in the retail market, the demands on warehouses and distribution centers across the globe are also rising.

Designing a warehouse layout seems like a simple undertaking, but it’s actually quite complex. In fact, the design and layout of your warehouse can make or break your operation’s productivity, impacting picking time, labor hours, and even increasing safety risks through poor traffic flow.

We’ve rounded up expert warehouse design and layout ideas, tips, and strategies to help you design the ideal layout for your facility to optimize productivity and enhance safety:

- Warehouse Layout Planning Tips

- Considerations When Designing a Warehouse Layout

- Warehouse Layout Design Ideas

From higher customer expectations — such as an increase of available product SKUs, overnight delivery, and free returns — to e-commerce brands offering both online and brick-and-mortar shopping and pickup options, the future indicates a need for more warehouse square footage that is managed efficiently to meet these demands.

Warehouse Layout Design

The Need for Storage and Warehousing – Warehouse Layout Design:

A warehouse is a point in the supply chain where raw materials, work-in-process, or finished goods are stored for varying lengths of time. A public warehouse is a business that rents storage space to other firms on a month-to-month basis. They are often used by firms to supplement their own private warehouses.

- Warehouses can be used to add value to a supply chain in two basic ways:

- Storage—allows product to be available where and when it’s needed.

- Transport economies—allows product to be collected, sorted, and distributed efficiently.

Warehouses only add value if the benefits of storing products in a warehouse enough to offset the additional cost associated with carrying any inventory.

warehouse layout optimization

Other potential benefits associated with storage include the following: time bridging, which allows the product to be available when it is needed (e.g., storing spare machine parts at the facility); processing, where for some products (e.g., wine), storage can be considered as a processing operation because the product undergoes a required change during storage; and securing, e.g., nuclear waste storage.

In production, ideally, raw material should arrive at a manufacturing facility just when it is needed and then immediately processed, the resulting products should be fabricated and assembled without delay, and the final finished products should be immediately shipped to their customers; in this situation (what could be termed pure “Just-In-Time” or JIT) there is little need for buffering or storing materials. In practice (including real-world JIT), there usually are economic benefits associated with the buffering and/or storage of raw materials, work in process (WIP), and/or finished goods.

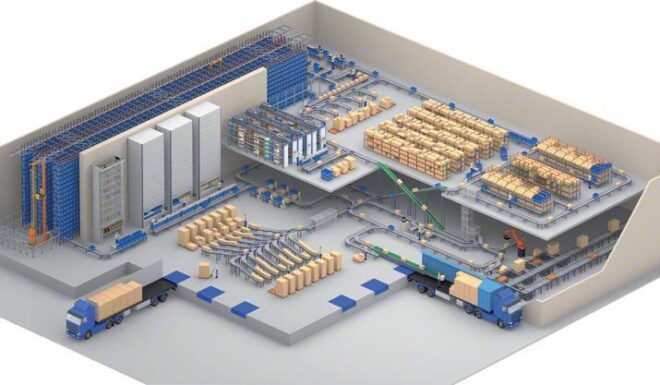

In distribution, the ideal of no storage can sometimes be realized using cross-docking, where there is a direct flow of material from trucks at the receiving docks to the shipping docks without buffering or storage in-between, but cross-docking requires detailed planning and coordination (e.g., implemented using EDI) that in many cases may not be feasible.

In most cases, the benefits associated with buffering and storage are due to the fixed costs associated with the other elements of production and the impact of variability pooling on achieving a target service level. Storing a product allows the other elements of production to operate more efficiently on a per-unit basis because the fixed costs associated with utilizing the element can be spread over more products; e.g., storing up to a truckload of product in a facility reduces the per-unit costs of shipping, and WIP buffering or storage enables batch production, which reduces the per-unit setup costs.

Storage System Design

Each distinct type of load is termed an item or stock-keeping unit (or SKU); e.g., each different style, size, and color of a garment would be assigned a unique SKU. Units of each item are stored in slots (short for storage location). A slot is a generic term for any of a variety of different types of identifiable storage locations (e.g., racks, bins, marked-off floor areas for block storage). Each slot-item combination has an associated capacity corresponding to the number of units of the item that can be stored in the slot.

The handling costs for the units within an SKU can usually be minimized by always storing and retrieving a unit at the nearest (i.e., least handling effort or cost) available location, or what is termed a closest open location (or COL) policy. As long as the inventory levels of each SKU are controlled, a COL policy will result in an approximate uniform rotation of the items; but, if inventory is not controlled, using a COL policy can result in items remaining at far away slots for a long time. If a strict uniform rotation of the items is required (e.g., due to the items being perishable), then a first-in, first-out (or FIFO) policy can be used. In addition, a last-in, first-out (or LIFO) policy can be used.

Design Trade-Off

As shown in Table 1, warehouse design involves the trade-off between building and handling costs. Handling costs usually dominate building costs when a warehouse is only used for short-term storage while building costs dominate for longer-term storage.

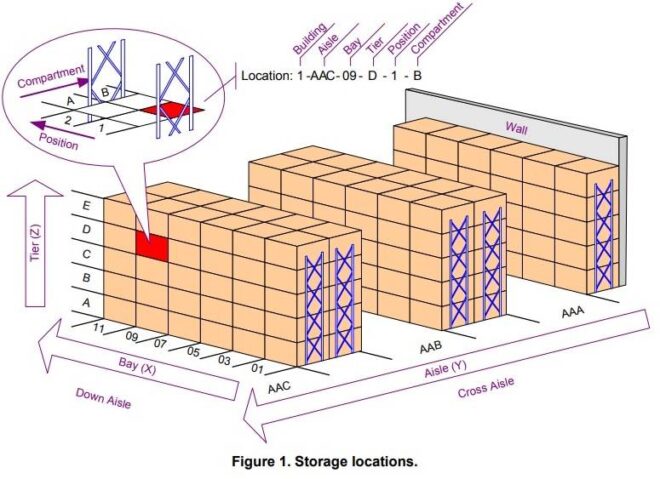

Storage Locations

Each accessible storage location in a warehouse is assigned a unique address. Multiple units of an item assigned to a single location correspond to the capacity of the location. It is common to alternate between numeric and alphabetic characters in an address to improve readability and to use even and odd numbers to designate each side of a down aisle.

- The single address scheme shown in Figure 1 can be used for each different storage medium in the warehouse:

- Pallet racks: Compartment dimension not used since only the front unit of each position is accessible.

- Shelves: All dimensions can be used if the compartment dimension is accessible.

- Drawers: Position dimension not used if the drawer has odd-shaped compartments.

- Block stacking: Only building, aisle, and bay dimensions used to address each lane of storage.

- Misc. locations: Receiving, shipping, holding areas, outdoor trailer storage, etc., can all be given unique addresses.

Storage policy warehouse

For multiple SKUs, three types of storage policies (see Figure 2) can be used to select storage locations (or slots):

- Dedicated (or Fixed Slot) Storage—each SKU has a predetermined number of slots assigned to it.

The total capacity of the slots assigned to each SKU must equal the storage space corresponding to the maximum on-hand inventory of each individual SKU, where the actual storage space might be greater than this due to “honeycomb loss.” Minimizes handling costs and maximizes building costs. Control is not difficult because each lane can be identified with a permanent label.

- Randomized (or Open Slot or Floating Slot) Storage—each SKU can be stored in any (usually the closest) available slot. The total capacity of all the slots must equal the storage space corresponding to the maximum aggregate on-hand inventory of all of the SKUs, where the actual storage space might be greater than this due to honeycomb loss. Minimizes building costs and maximizes handling costs. Control is more difficult than dedicated storage because the identity of SKU stored at each slot needs to be recorded for retrieval purposes.

- Class-based Storage—a combination of dedicated and randomized storage, where each SKU is assigned to one of several different storage classes. Randomized storage is used for each SKU within a class, and dedicated storage is used between classes. Building and handling cost in-between dedicated and randomized. Classes can be formed from SKUs whose individual on-hand inventory is negatively correlated (or, at least, uncorrelated).

Dedicated vs random storage

Storage policy warehouse:

Based on just storage space requirements, a randomized policy would be preferred; but a dedicated or class-based policy may be preferred because they can sometimes reduce the handling requirements enough compared to randomized to offset their increase in storage requirements (this is an example of the trade-off between building and handling cost).

In general, as long as the on-hand inventory of each SKU is not at its maximum at the same time, randomized storage will require a lesser number of slots as compared to dedicated storage.

A combination of dedicated and randomized storage termed “supermarket” storage is used in most less-than-unit-load order picking operations, where randomized storage is used for reserve stock and dedicated is used for forwarding stock.

Cartons are picked from forwarding stock (in flowthrough racks), and full pallet loads of cartons are taken from reserve stock (in bulk storage) and used to replenish the forward stock.

Cube Utilization and Honeycomb Loss

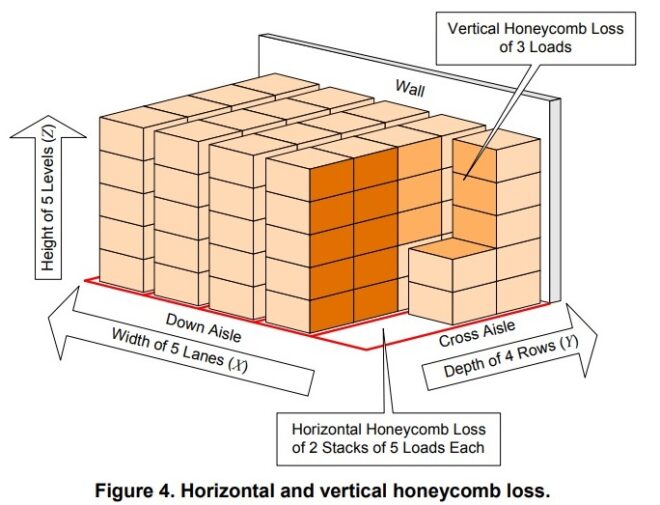

When storing multiple SKUs in a single region, full utilization of all of the available space is not desirable because it could result in some items not being accessible. Honeycomb loss, the price paid for accessibility, is the unusable empty storage space in a lane or stack due to the storage of only a single SKU in each lane or stack since storing items from different SKUs would block access.

The empty space associated with partially filled lanes and stacks is termed “horizontal” and “vertical” honeycomb loss, respectively (see Figure 4). When a single SKU is stored in a region, there need not be any honeycomb loss since the depth and height of the region can exactly match the storage space need for the SKU.

Cube utilization is the percentage of the total space (or “cube”) required for storage actually occupied by the loads being stored.

There is usually a trade-off between cube utilization and material accessibility:

- increasing cube utilization -> decreased accessibility

- increasing accessibility -> decreased cube utilization.

Bulk storage using block-stacking can result in the minimum cost of storage since cube utilization is high and no storage medium is required, but material accessibility is low since only the top of the front stack is accessible and loads at bottom of a stack must not require support. Storage racks are used when support and/or material accessibility is required.

Estimating Handling Costs

Minimizing handling costs usually increases building costs, where the cost of racks, etc., are included as part of the building costs. Warehouse design involves determining the best compromise between these issues. Handling costs can be estimated by determining:

- Expected time required for each move based on an average of the time required to reach each slot in the region.

- A number of vehicles needed to handle a target peak demand for moves, e.g., moves per hour.

- Operating costs per hour of vehicle operation, e.g., labor, fuel.

- Annual operating costs based on annual demand for moves.

- Total handling costs as the sum of the annual capital recovery costs for the vehicles and the annual operating costs.

The most read

Pallet Racking system

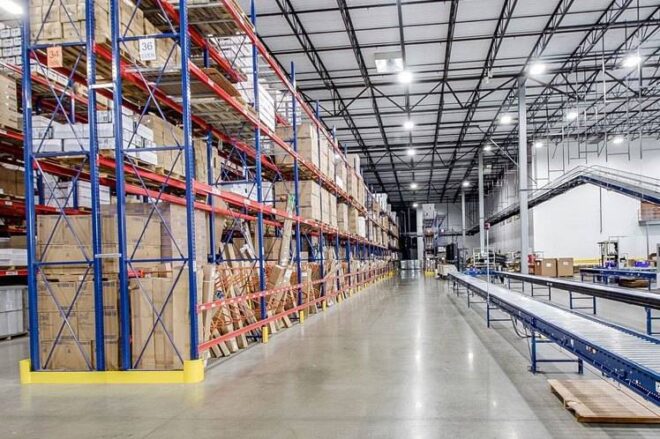

Selecting warehouse storage rack systems involves careful planning and appropriate system choices to ensure you get the most from your capital expenditures, reduce overhead, and respond quickly to distribution needs.

Pallet Racking Types

Pallet racking is a material handling storage rack system designed to store products and materials on pallets in horizontal rows and on multiple levels. Most warehouses prefer using pallet racking systems to maximize the storage space they have available.