In a manufacturing plant, it is essential to provide an overhead travelling crane to transport heavy components of machines from one place to another. The movement of the load is of three-dimensional nature.

The crane is required to lift heavy mass vertically and horizontally, also the crane with load is required to move along the length of the shed.

The cranes are either hand-or-electrically operated. The crane moves on rails which are at its ends. The rails are provided on a girder known as a gantry girder. The gantry girder spans over gantry columns.

If the capacity of the crane is moderate, the gantry girders rest on brackets connected to the roof column of an industrial shed.

- Characteristics

- The design of the gantry girder is a classic example of a laterally unsupported beam

- It is subjected to in addition to vertical loads and horizontal loads along and perpendicular to its axis

- Loads are of dynamic nature and produce vibration

- Compression flange requires critical attention

Components of plate girder:

The plate girder consists of the following components:

- The web plate

- Flange plate (addition of cover plate curtailed at proper sections)

- Stiffeners like bearing stiffeners, longitudinal stiffeners, and intermediate stiffeners

- Splices for flange plate and web plate

- End connections

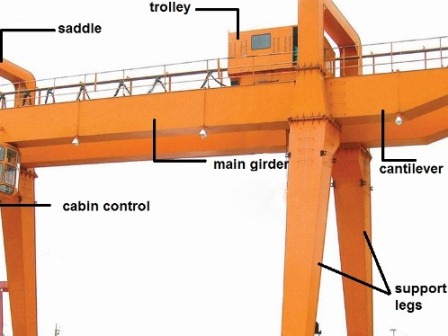

Gantry Crane Parts

Gantry cranes are among the most widely used industrial crane varieties. They are very similar in nature to bridge cranes; the only substantial difference between the two configurations is gantry cranes’ mobility compared to bridge cranes.

Gantry Crane Design

As a special series of lifting equipment, there are different types of gantry cranes. The classification of the gantry cranes can be listed according to several factors.