Gantry cranes are among the most widely used industrial crane varieties. They are very similar in nature to bridge cranes; the only substantial difference between the two configurations is gantry cranes’ mobility compared to bridge cranes.

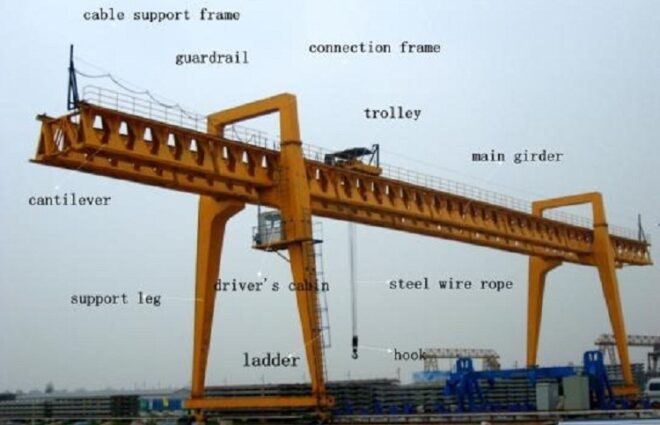

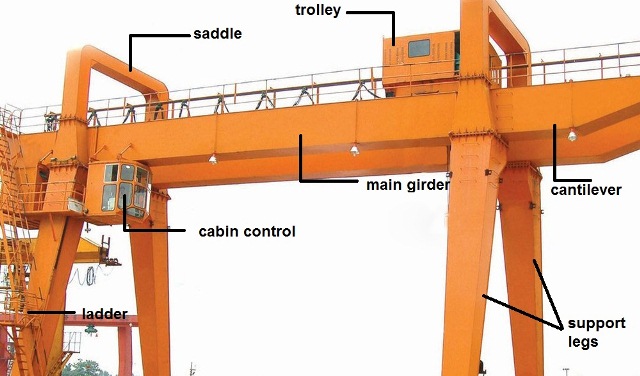

This section briefly describes the main components that constitute a gantry crane.

Main Girder

Together with the supports, it forms the basic structural system of the crane. Its mission is to serve as a platform for the movement of the carriage-hoist unit as well as to support the efforts it receives from it. In addition, it can house the control cabin, various electromechanical systems or access gateways for maintenance.

It is formed by a metallic girder of high dimensions. The main structure of these cranes is basically formed by box type girder in steel sheet with a minimum thickness of 8 mm.

Support Legs

They are responsible for receiving the load transmitted by the beam and channel it to the ground. In addition, like the beam, they can accommodate the cockpit, electromechanical systems and access stairs.

Trolley

It is the structure that supports and houses the components that form the lifting system for cranes equipped with an open winch or to support the hoist for cranes equipped with this type of component.

It can be built as a unit or in sections depending basically on its weight and dimensions.

Its shape, dimensions, and weight are variable since they are designed and built according to the needs of each crane, which vary according to their load capacity and type of service.

The trolley serves as a support for the hoist. It is provided with an electromechanical group that allows it to move along the beam.

Technical Specifications

The end trucks for bridge translation shall be made of structural steel in the shape of a box and resist all combined forces, vertical, lateral, and torsion, caused by live loads, dead loads, impact loads, accidental loads, and dynamic loads caused by the operation of the crane.

The maximum permissible deformation produced in the bridge by the dead weight, the weight of the carriage, and 125% of the nominal static load, shall not exceed 1/8 of the clear.

The impact load should not be considered in this deflection. The carriage must have a counter flex equal to the deflection produced by the dead load plus half of the deflection produced by the live load.

The cars must have lifting points (lifting lugs or eye bolts or similar) to allow easy assembly on site of the work.

Crane hook

The hook and hoist rope is a machine composed of two or more pulleys and a rope, cable or chain that alternatively goes through the various threats of each of those.

They allow lifting a load exerting a force less than the weight that must be moved.

The hoist is the mechanism that allows the vertical displacement of the load taking advantage of the mechanical advantage produced by the action of at least two pulleys. The branches can be chains, when the loads are light, or steel cables.

Technical specifications

The main hook of the crane can be of the type of double peak built-in forged steel, supported by thrust bearings of balls or rollers to allow full rotation around its vertical axis.

The auxiliary hook can be of a single peak (standard) and with the other characteristics pointed for the main hook.

Factory voltage testing of each hook must be performed.

The movement of the auxiliary hook will be independent of the movement of the car and will move along the outer bridge beam near the side walls.

For maintenance purposes of the auxiliary lift, a platform must be provided for this purpose, accessible from the overhead crane.

Both hooks, main and auxiliary must have a mechanical safe The pulley holder must be supplied with the necessary accessories to lubricate the bearings of each of the pulleys.

You must have the provisions to prevent the cable from getting out of the slots. In addition, there must be a system that compensates for any distension of the cables.

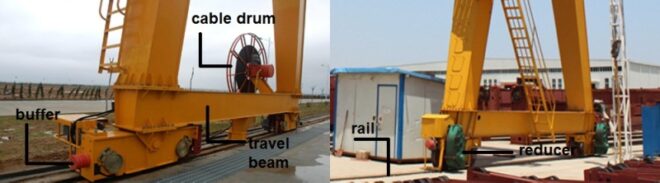

Mechanism of translation

The most common way of translating gantry cranes is through rails or pneumatic wheels. For this reason, the supports support bogies or frames equipped with wheels that are moved by electromechanical groups.

Steel wire rope

The lifting cables must be specifically for the service of cranes; flexible, self-lubricating, improved plow steel (the tensile strength can be between 180 and 200 kgf / mm2), be of 6 strands of 37 threads or 6 strands by 19 threads, with steel core, the design and construction of the cable must comply with what is specified according to technical standards.

The effort produced by the nominal load plus the weight of the rigging of the hook in each of the cables, shall not be greater than 20% of the last effort of the material of the same.

The correct grease for the cable must be supplied by the contractor, within this supply, the necessary amount of grease must be considered for the assembly of the bridge, for two additional re-lubrications during the operation process of the Crane in the assembly of the equipment of the Central and for the first maintenance of the Crane.

Gantry crane port

When it comes to lifting specialization, gantry cranes deliver. From one-ton indoor single-leg workstation gantries to massive 1,000-ton double-leg rail-mounted gantries found in shipyards, coker units, concrete yards, mining operations, and steel storage yards, gantry cranes provide unmatched lifting versatility.

A gantry crane is a crane built atop a gantry, which is a structure used to straddle an object or workspace. They can range from enormous “full” gantry cranes, capable of lifting some of the heaviest loads in the world, to small shop cranes, used for tasks such as lifting automobile engines out of vehicles.

Basically, gantry hoists are used to move lengthy and bulky objects and are typically taken advantage of at industrial warehouses of a large area or open construction sites.

Gantry hoist construction is in demand in hangars and workshops of enterprises engaged in the production of concrete products, and freight yards.

In addition, the cranes are widely used to perform a variety of cargo handling, lifting, and installation work on container platforms of railway junctions.

A gantry crane is slightly different from a bridge crane. The general premise is the same, but the operation is different. Gantry cranes have a bridge that is supported by two a-frame rigid steel legs that rest on the floor.

The Overhead crane operates on an elevated runway system along the length of a building. Gantry cranes are usually less expensive than an overhead bridge crane.

The most read

Components of Gantry Girder

A gantry crane is a serious purchase. Not only are they expensive, but they are relied upon to lift seriously heavy objects.

Portable Gantry Crane

Reach all corners of your plant. Lift and move materials, or use for pulling motors, equipment, and other heavy machinery. Quick disassembly for transport by a service truck.

Indoor Gantry Crane

Gantry cranes can be adapted both indoors and outdoors where heavy materials are required to be lifted and moved.