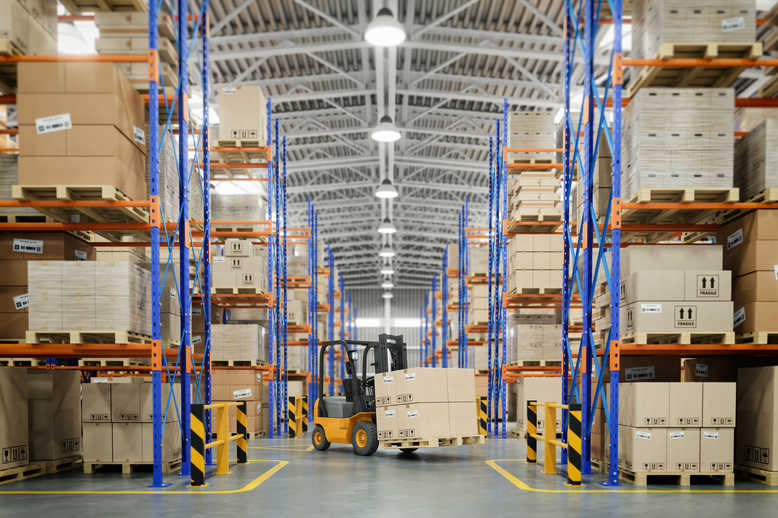

Warehouse Racking Design: The efficient, safe design and use of pallet racking storage systems, pallets and materials handling equipment depend on a number of factors.

This guide is intended to give an indication of best practice and advice to anyone involved in the planning of a new warehouse or storage facility.

It is of equal value to the warehouse manager/operator for information on operation, maintenance and health and safety matters for those who may not be a specialist with regard to this type of equipment or in the detail design related to the storage facility.

Covering Industry and Technical Standards and relevant storage and warehouse legislation this guide is a handy reference tool for any personnel working within a warehousing/operations environment.

Warehouse racking layout

Warehouse and Storage Planning

Warehouse planning and implementation

Warehouse racking design: Warehouse Planning Do’s and Don’ts:

Design from the inside, out: Warehousing is all about efficient space utilization and cost-effective materials handling. These essentials must be considered first, before the building structure

- The roof is only there to keep out the weather!

- It is more economical to build upwards than outwards (per cubic meter of space)

- Think building volume, not floor area, in storage zones

- Think of the amount of activity that is to take place and ensure that adequate movement space is also provided

- Building related costs are often quite high, largely “fixed” and can literally become a “millstone around your neck” if you get your planning wrong!

Unitise and Standardise: Whether handling small parts, palletized goods, or large loads, make sure that you:

- “Unitise” goods for ease of handling and storage

- Use industry-standard pallets and containers to eliminate double-handling, minimize the risk of product damage and make the best use of space

- Minimize the number of different standard sizes and loaded weights of the unit load devices that you use in order to maximize flexibility

- Instruct your suppliers to use only those standard-sized units, in order to minimize transport and handling costs

- Work with your customers to deliver in standard unit load quantities and lot sizes, in order to minimize handling and delivery costs

Warehouse implementation plan

Plan for Good Space Utilisation: Space costs money ….. Use it wisely

- Use Pareto (A, B, C) analysis to categorize products according to their storage, handling, and throughput characteristics

- Use the available building height to maximum advantage

- Select storage systems which offer good space utilization good selectivity stock rotation

- Select handling equipment which complements the storage systems and also facilitates good space utilization (i.e. which will allow you to work with the narrowest practicable aisles)

- Remember, handling and storage equipment usually accounts for only a relatively small proportion of total warehousing costs. Investment in the right equipment can save a great deal more, both in terms of building costs, and labor costs

Warehouse material handling equipment

Plan for Efficient Materials Handling Flow

- Why meander when you can travel in straight lines?

- Through-flow or ‘U’ flow?

- Plan flow-efficient layouts in terms of:

- stock layout (by-product popularity or another appropriate grouping)

- processes, including receiving, putaway, picking, packing, and despatch

- Select appropriate types of handling equipment according to:

- the types of load to be moved

- the rates of movement

- travel distances

Plan for Productivity

warehouse racking design:

- Labor costs are usually controllable; therefore minimize them

- Benchmark your performance against “best in class”

- Focus on Order Picking – it can account for half or more of labor costs. Identify picking methods which:

- reduce picker travel distances

- maximize accuracy

- eliminates paper encourage high productivity, or

- bring the goods to the picker

- Introduce performance standards

- Monitor individual and group KPI’s and performance

- Train staff

- Reward good performance

Warehouse dimensions

Prepare the building performance specification only after planning the storage and handling systems and internal layout. (warehouse racking design )

- Key items to specify, include:

- Dimensions of the structural column grid

- Clear operating height from floor to top of the very top load

- Floor loadings, flatness, and finishes

- Loading dock arrangements

- Mezzanine floors; heights, types, and loadings

- Lighting levels, heating, and environmental needs

- Fire protection and compartmentalization

- Offices and employee amenities

warehouse best practices

Think outside the box – avoid congestion: At large D.C.’s over 60% of site area can be allocated to roadways, parking, and external activities.

Make sure that:

- The site has a secure perimeter

- Employee car parking is secure and separated from the main site

- Proper routes are defined and marked for commercial vehicles

- Adequate parking is provided for commercial vehicles and private cars

- All-access and egress is controlled, security-wise

- Pallets, cages, and waste are stored in properly designated, enclosed areas

- Pedestrian routes are safe and properly defined

- Plan to avoid congestion: Don’t over-develop the site !!

Future of warehouse

Future Proof the Design – Business is Dynamic. Future-proof your investment, in terms of:

- Process flexibility

- Process reliability

- Process resilience

- Reverse logistics

- Allowing for future changes in

- business needs

- product ranges

- stockholding policy

- customer demands

- Changes in handling and storage technology and Information Technology

- Ultimate property disposal

Warehouse racking codes

Planning your Racking & Storage:

Matching business needs with the appropriate pallet racking system is critical and entails asking the right questions as well as providing flexibility in solutions that can accommodate variables such as capital resources, anticipated growth, and variable product lines.

Choosing the right storage system involves a solution process, and that begins with considering the flow of merchandise. That will dictate your density requirements – how “tightly” the merchandise should be stored. From that key decision follows a series of specifications: the material and type of racking, pick systems, ancillary material handling, etc.

Warehousing with high-density storage solutions usually has a large or complete turnover of inventories during specific intervals or seasons. Merchandise could be stored in large bays with a few access aisles to maximize floor space.

Conversely, lower density warehousing is appropriate for parts or retail distribution centers where customer orders are picked continuously to fulfill Just In Time (JIT) requirements.

Warehouse Racking Design

Storage Analysis & Planning: The data collection stage of the design process defines data requirements and results in the development of two “Planning Bases”.

- Today’s picture of flows and quantity movements.

- Tomorrow’s requirements, which may show the transitional steps at specific time-points where significant events are expected to take place e.g. new product launches or new contracts expected/lost.

In almost all circumstances it is important to gain an understanding

of the following;

- How are the goods received and in what volume? How are they expected to be received and to be stored and put away – and at what rates and volumes?

- Which product lines are expected to be held as stock – together with the physical characteristics for each stock keeping unit (SKU) passing through the warehouse?

- What volume of goods needs storing in each of the family or subgroups?

- What are the typical order profiles (analyzed by division and family groups or subgroups)? Must orders be checked and/or repacked? What are the work content and physical volume to be handled in each task area?

- Must goods be staged if they cannot be direct-loaded? What is the quantity of inbound and outbound vehicles the facility will need to provide for within the warehouse area (for undercover loading) and within the yard, including any stand trailers or containers?

- What additional yard space should be allocated to product handling equipment, such as pallets, and should these be of a consistent size for ease of operating the warehouse?

What effect do days of the week or month or other seasonal factors

have on the throughputs and inventory levels? There are two basic data collection tasks that almost always apply:

- warehouse analysis and improvement

- Movement Analysis

warehouse analysis and improvement

Storage Analysis: Defining the right balance between the conflicting objectives of efficient storage and frequent order accessories (picking slot visits) is a key part of the decision process. This balance can only be achieved after proper analysis of product lines to be stored and the rates at which they have to move through the warehouse. In this regard compilation of ranked product storage and ranked product movement rate data is invaluable.

Warehouse racking design

To demonstrate this in graphical form, the storage analysis graph in Figure 1.1 shows the number of pallets to be stored for each line. This information combined with the total quantity of pallets or units to be stored provides a very good guide in the selection of storage systems.

Movement Analysis

A movement graph, as illustrated in Figure 1.2 shows the rate at which each product line moves through the warehouse with indications of whether it moves out in pallet or carton quantities.

This provides further guidance to the selection of storage system and the most appropriate handling equipment and, in particular, the order picking system.

In a small operation, this information may be observed manually. As the size and complexity of the warehousing requirement grows, the only practical way to define requirements is to collect data in electronic form and develop a database, allowing the data to be manipulated as required. Typical measures would include number of pallets per day, (e.g. a number of picks or order lines per day), based on known ratios or validated assumptions.

Planning the building footprint and layout

Critical components of a building footprint as it relates to a pallet

racking is:

- Building column layout

- Building clear height (usable vertical space below the roof or ceiling)

- Overall square footage

- Permanent and semi-permanent obstructions (offices, sprinklers, lighting, etc.)

- The simplicity of building layout (a rectangular building is typically more conducive to efficient storage design than one that has large square footage through multiple build-outs)

- Dock door placement

- Safety requirements (egress paths, forklift aisles, etc.)

The goal of warehouse designing is to optimize warehousing operations and achieve maximum efficiency. Maximum efficiency can be reached by implementing solutions. In short, the warehouse design element aims to maximize the utility of space, equipment, and efficiency of operations.

A well-optimized layout also helps employees to ensure time-bin replenishment to make sure the warehouse has optimum space utilization, reduce storage costs, and improve employee efficiency.

Pallet/Gravity Flow: Pallet flow rack uses metal rollers and the force of gravity to feed pallets into the rack’s pick position and is used for its ability to get warehouses flowing. Like drive-in racking and other engineered systems, pallet flow works by eliminating aisles in order to maximize the available space.

The most read

Warehouse Storage Solutions

There are a number of warehouse storage solutions out there, and while a couple of these may ‘work’ for your operation, there’s likely one that is the most beneficial. Identifying and utilizing this ideal storage solution will ensure optimized density and selectivity, increasing efficiency, and ultimately profits.

Types of Racks in Warehouse

Racking is much more than just steel. Racking is the key to optimum throughput efficiency because the efficiency of the entire material flow is optimized only through the requirement-specific design of a racking system.