Using infrared thermometer: Temperature is the most frequently measured physical quantity, second only to time. Temperature plays an important role as an indicator of the condition of a product or piece of machinery, both in manufacturing and in quality control. Accurate temperature monitoring improves product quality and increases productivity. Downtimes are decreased since the manufacturing processes can proceed without interruption and under optimal conditions.

Infrared technology is not a new phenomenonóit has been utilized successfully in industrial and research settings for decadesóbut new innovations have reduced costs, increased reliability, and resulted in noncontact infrared sensors offering smaller units of measurement. All of these factors have led infrared technology to become an area of interest for new kinds of applications and users.

Advantages of Using Infrared Thermometers

What are the advantages offered by noncontact temperature measurement?

- It is fast (in the ms range)ótime is saved, allowing for more measurements and accumulation of data (determination of temperature field).

- It facilitates the measurement of moving targets (conveyor processes).

- Measurements can be taken of hazardous or physically inaccessible objects (high-voltage parts, great measurement distance).

- Measurements of high temperatures (greater than 1300°C) present no problems. In similar cases, contact thermometers cannot be used, or have a limited life.

- There is no interferenceóno energy is lost from the target. For example, in the case of a poor heat conductor such as plastic or wood, measurements are extremely accurate with no distortion of measured values, as compared to measurements with contact thermometers.

- There is no risk of contamination and no mechanical effect on the surface of the object; thus wear-free. Lacquered surfaces, for example, are not scratched and soft surfaces can also be measured.

Having enumerated the advantages, there remains the question of what to keep in mind when using an IR thermometer:

- The target must be optically (infrared-optically) visible to the IR thermometer. High levels of dust or smoke make measurement less accurate. Concrete obstacles, such

as a closed metallic reaction vessel, allow for only topical measurementóthe inside of the container cannot be measured. - The optics of the sensor must be protected from dust and condensing liquids. (Manufacturers supply the necessary equipment for this.)

- Normally, only surface temperatures can be measured, with the differing emissivities of different material surfaces taken into account.

The main advantages of noncontact IR thermometry are speed, lack of interference, and the ability to measure in high-temperature ranges to 3000°C. Keep in mind that only the surface temperature can be measured.

Infrared Thermometer system

The Infrared Measuring System:

An IR thermometer can be compared to the human eye. The lens of the eye represents the optics through which the radiation (flow of photons) from the object reaches the photosensitive layer (retina) via the atmosphere. This is converted into a signal that is sent to the brain.

The Target:

Every form of matter with temperature (T) above absolute zero emits infrared radiation according to its temperature. This is called characteristic radiation. The cause of this is the internal mechanical movement of molecules. The intensity of this movement depends on the temperature of the object.

Since the molecule movement represents charge displacement, electromagnetic radiation (photon particles) is emitted. These photons move at the speed of light and behave according to the known optical principles. They can be deflected, focused with a lens, or reflected from reflective surfaces.

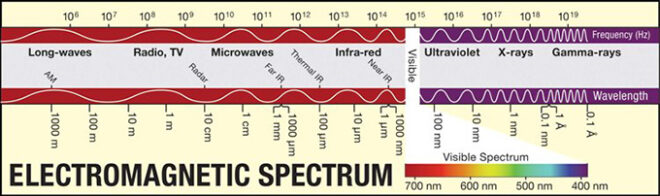

The spectrum of this radiation ranges from 0.7 to 1000 µm wavelength. For this reason, this radiation cannot normally be seen with the naked eye. This area lies within the red area of visible light and has therefore been called “infra”-red after the Latin.

What is infrared technology?

Infrared technology is increasingly present in mainstream industrial applications. Before asking ‘what is infrared technology?’, we need to clarify our understanding of infrared radiation. Visible ‘light’ accounts for a tiny amount of the radiation that exists around us, our eyes are only capable of seeing a narrow region of the electromagnetic spectrum, and we need specialist technology to see what lies beyond.

Microwaves, radio waves, ultraviolet rays, and infrared are all forms of radiation that’s invisible to us, but their presence is felt nevertheless, largely through radiated heat.

We use protective cream, for example, to protect us against the sun’s harmful UV rays, and x-rays (high energy, short wavelength radiation) are used extensively to penetrate our skin and reveal fractures in bone in a way that’s not possible by visible light.

Infrared, meaning ‘below red’, is radiation similar to visible light, but with a slightly longer wavelength.

It has less energy than red light – which is the lowest energy light the human eye can perceive. Whilst visible light is emitted by objects at a very high temperature, infrared energy is emitted by all objects at room temperature and below. Now, all objects have the ability to absorb and emit radiated heat, but at different values.

Dull and dark objects such as concrete and rubber, for example, will retain and emit more heat under identical conditions than reflective objects like steel. But generally, the hotter the object, the greater the amount of infrared energy is emitted. The human body emits a vast amount of heat that’s difficult to perceive without specialist infrared technology.

What is infrared technology used for?

Let’s consider measuring this emitted heat…

By using sophisticated technology, we can detect emitted infrared energy. Taking the human body as an example, infrared thermal image cameras can detect our infrared heat signature in total darkness.

You may have seen an image taken by a police helicopter camera of suspects on the run at night, showing the hottest areas as bright white, typically being car tyres, street lighting, or human skin.

Thermal imaging systems not only let you see in the dark, but they also enhance your ability to detect excessive or inadequate temperatures of critical objects, assess energy loss and protect the environment, and evaluate building diagnostics.

They are an invaluable, affordable tool for businesses specialising in transportation, construction, environmental monitoring, electrical installation, and security.

An alternative to the infrared thermal image camera is the infrared thermometer. These thermometers use sophisticated optics to measure radiated heat.

Often being equipped with a laser, they are designed for instant non-contact temperature measurements of inaccessible, hygienic, or hard-to-reach flat surface areas, such as air conditioning systems, industrial machinery, automotive spot checks, and food preparation surfaces.

Infrared thermometers safety tips

Carefully read the instructions that come with the thermometer. Before and after each use, clean the tip of the thermometer following the instructions for your particular thermometer. If you plan to use a digital thermometer to take a rectal temperature, get another digital thermometer for oral use. Label each thermometer, and don’t use the same thermometer in both places.

For safety — and to make sure the thermometer stays in place — never leave your child unattended while you’re taking his or her temperature.

Yes, you can use a general-purpose medical infrared thermometer to measure human-forehead temperature. Also, you must lower your expectations if you want accurate reading because it doesn’t generally happen with these thermometers.

Your child has a fever if he or she: Has a rectal, ear, or temporal artery temperature of 100.4 F (38 C) or higher. Has an oral temperature of 100 F (37.8 C) or higher. Has an armpit temperature of 99 F (37.2 C) or higher.

The most read

Infrared Thermometer made in USA

- What is Top 10 Thermometer Made In the USA in 2020?

- What is the best medical infrared thermometer made in the USA?

- What is the best-infrared thermometer made in the USA?

Industrial Digital Thermometer

Industrial thermometers are used for temperature measurement in many industrial applications. They are generally more durable than laboratory thermometers.