Infrared Thermometer Calibration: Regular IR thermometer calibration ensures that your device is operating at its highest possible level of accuracy. Infrared thermometer calibration is deceivingly complex. With multiple sources of uncertainty, a host of outside considerations, and a variety of specialized equipment required, it’s best to leave this job to the pros.

Your infrared (IR) digital thermometer is as much a safety device as it is a measurement device, as quick response times and noncontact capabilities allow you to minimize time spent around potentially dangerous equipment.

Infrared thermometer calibration equipment

What Is an Infrared Thermometer Measuring?

An infrared thermometer is a non-contact thermometer since it doesn’t touch the surface being measured. It measures thermal radiation in the infrared region of the electromagnetic spectrum beyond where the eye can see.

A common spectral band for measuring temperatures from below ambient up to 500 °C or 1000 °C. This is partly because, at room temperature, the peak energy occurs just below 10 µm.

As temperatures get higher, this peak wavelength becomes shorter. Most people have seen a “red hot” piece of metal. This is because the human eye can see this thermal radiation.

The metal is red hot because the radiation has a significant enough amount of energy in the shorter wavelengths where the human eye can see, between 0.3 and 0.7 µm. This occurs at some point above 600 °C. The Sun’s surface temperature is a temperature between 5000 and 5500 K. The peak wavelength for these temperatures is roughly 0.5µm, right in the middle of the range visible to the human eye.

infrared thermometer calibration standard

There are a number of factors that can increase uncertainty and cause errors when using infrared thermometers. An adequate uncertainty budget should help point these out. There are two which cause people more problems than others, emissivity, and size-of source.

Infrared thermometer calibration service

Preparation of Calibration procedure:

Before the calibration, the infrared thermometer should be allowed enough time to reach the temperature of the laboratory, typically 15 minutes. This is an especially important consideration when bringing a thermometer in from the outside.

For most calibrations, cleaning the infrared thermometer’s lens is not recommended. Any lens cleaning that is done should be done with the permission of the customer and according to the infrared thermometer’s manufacturer’s recommendations.

The radiation source should be set to the desired calibration temperature and should be allowed to stabilize. If the calibration is to be done with a dry gas purge, the purge shall be set up before the radiation source stabilizes.

Calibration points

- The customer should determine the calibration points used. They should be based on the customer’s wants and needs. If the customer does not know what calibration points he/she wants, the calibration laboratory may offer advice.

- If the infrared thermometer is used over a narrow range of temperatures, one calibration point may be enough. For an infrared thermometer used over a wide range of temperatures, at least three points should be used. These points should represent at least the minimum, maximum, and mid-range of the infrared thermometer’s usage range.

- The order of the calibration points may be chosen in an arbitrary fashion. However, due to the phenomenon of thermal shock, it is best practice to perform the lower temperature calibration points first and the higher calibration points last.

Reporting your results

The report of calibration is a communications tool for you and your customer. The report should be in a standardized form and meet the requirements of your laboratory’s accrediting body.

The results of the calibration should be reported. This is best represented by a table of source temperatures versus infrared thermometer readout values. An indication of PASS/FAIL may be made in this table as well. The report should include the following items:

- Title

- Unique identification of the calibrated infrared thermometer

- Record of the person who performed the calibration

- Date of calibration

- Source temperature versus infrared thermometer readout temperature

- Measuring distance

- Emissivity setting of the infrared thermometer

- The diameter of the source

- Ambient temperature

- Description of the aperture including aperture distance (if used)

- Measurement uncertainties

Other supplementary information such as a description of the calibration procedure, a list of reference instruments used, a statement regarding the traceability of the calibration, and a description of the uncertainty budget may be included in the report as well.

IR thermometer calibration

Before calibrating an infrared thermometer, the infrared thermometer should be allowed to reach room temperature. This is especially important when moving an infrared thermometer from one environment to another. Typically, 30 minutes is sufficient.

You use your IR thermometer so frequently that it’s easy to take it for granted.

The reality is that your device is only as accurate as of its last calibration, and the calibration is only as accurate as the equipment used in the process. Infrared thermometer calibration requires several specialized instruments, each of which must be professionally calibrated for a high degree of accuracy.

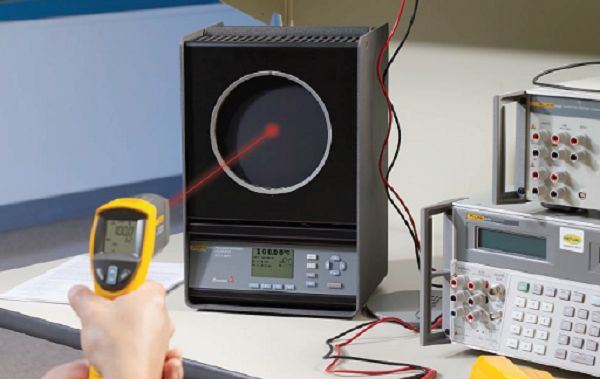

- Thermal Radiation Source: This device provides the heat that will be used to calibrate the infrared thermometer, and is itself calibrated to a specific set of standards. Temperature readings are taken at a set of specific points dictated by a governing body or your own specifications

- Transfer Standard: This instrument is used to calibrate the heat source, and must be traceable to BIPM through NIST or another national metrological governing body

- Ambient Temperature Thermometer: The temperature of the room in which the calibration takes place is an important factor in accounting for uncertainty, so the ambient temperature thermometer must itself be highly accurate if the resulting IR calibration is to be accurate

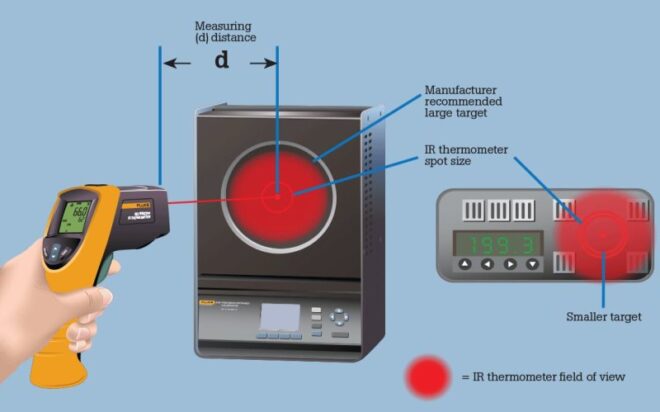

- Mount: There are several options for mounting the IR thermometer during calibration, but it is critical that the thermometer maintain a constant location in all three dimensions ‚ any movement in any direction alters the spot-to-distance (S:D) ratio, which is another important part of the calibration calculations

- Distance Measurement: The distance between the IR thermometer and the heat source is one-half of the S:D ratio, and must be measured by a precisely calibrated device if the IR calibration itself is to be accurate

The infrared thermometer calibration procedure

The basic infrared thermometer procedure for a calibration point should include the following steps:

- If a purge device is used, set up the purge.

- Allow the thermal radiation source to stabilize at its set-point

- If available, set the infrared thermometer’s reflected temperature setting to the reflected temperature.

- Set the infrared thermometer’s emissivity to the emissivity of the thermal radiation source.

- Set the measuring distance of the infrared thermometer.

- Align the infrared thermometer so that it is centered on the thermal radiation source.

- Perform the measurement.

- Repeat these steps for repeatability if needed.

There are a few notes and exceptions to consider when performing these steps. First, most infrared thermometers do not have a reflected temperature setting. Instead, the reflected temperature is detected within the instrument.

Second, some infrared thermometers do not have an adjustable emissivity setting. In these cases, if the emissivity setting of the infrared thermometer does not match the emissivity of the thermal radiation source, mathematical corrections may be made.

When using a handheld infrared thermometer, it is typical to initiate a measurement by pulling a trigger. The trigger should be held a significant amount of time longer than the infrared thermometer’s specified response time.

Finally, the number of set points measured should be driven by the customer. If the infrared thermometer is only used over a narrow temperature range, one or two points may be sufficient. If the infrared thermometer is used over a wide range, three or more points may be necessary. This should be driven by the customer. However, the calibration laboratory should be ready to offer advice.

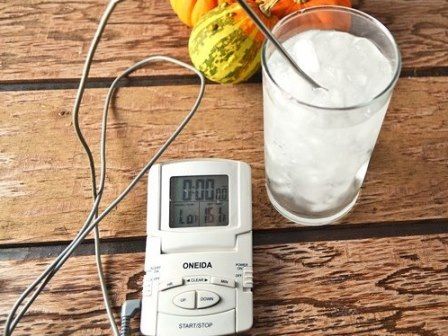

yes, infrared thermometers cannot typically be calibrated at home, but they are known for their low drift. If the results of your ice bath test are within your unit’s manufacturer’s listed specifications, you are good to go.

Calibration is important because it helps ensure accurate measurements, and accurate measurements are critical to the quality and safety of products and services. After the initial calibration, a technology check should be done every 12 months, while the unit calibration should be done every 2 years.

The most read

How to calibrate a digital thermometer?

A digital thermometer should always return accurate readings. Whether you use it for measuring body temperature, atmospheric temperature, or any other relevant use.

Temperature Calibration Equipment

Temperature calibration equipment offers superior performance in terms of accuracy, stability, and uniformity.

An easy way to Calibrate your Thermometer

Now more than ever it’s important to learn how to calibrate a thermometer. Since we’re not all so lucky to own the world’s best and most accurate thermometer.

Infrared Thermometer made in the USA

What are the Top 10 Thermometers Made In the USA in 2020? What is the best-infrared thermometer made in the USA?

Most Accurate Thermometer

Thermometers are indispensable today.