NIST thermometer calibration: Temperature is a critical measurement for ensuring the safety and quality of many food products. There are a variety of commercial temperature monitoring devices available.

Whether monitoring temperatures at receiving, throughout production or final product storage and distribution, thermometer calibration is essential. The validation, verification reassessment section of the Hazard Analysis and Critical Control Point, system stated in the Code of Federal Regulations, specifies that instruments used for monitoring critical control points must be calibrated.

NIST certified thermometer

The food industry is keenly aware of the critical nature of processing temperature requirements. Instrument calibration is not only a food safety issue but also an economic consideration since the accuracy of temperature monitoring devices also affects product yields.

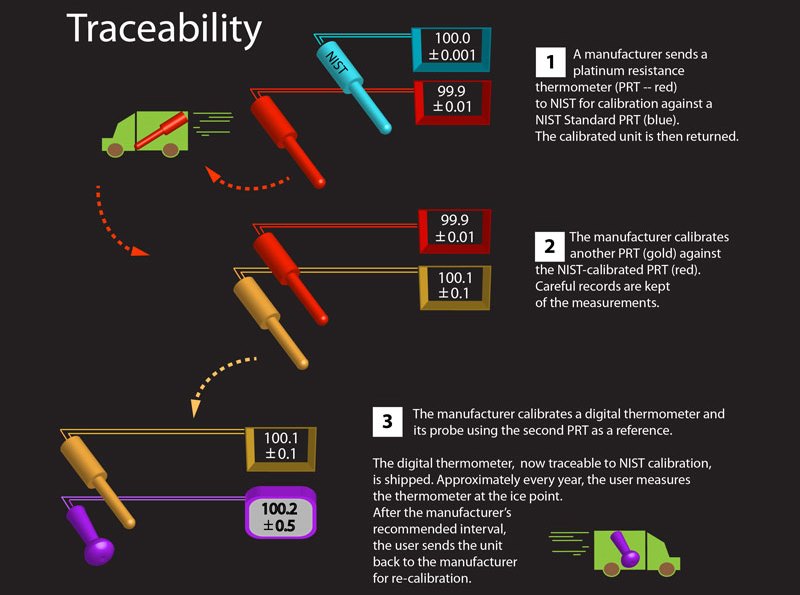

The National Institute of Standards and Technology (NIST) is an agency within the U. S. Department of Commerce which provides certification and calibration for thermometers and other precision instruments. When purchasing a thermometer check for the “NIST” label.

The NIST label indicates a certified instrument that will maintain accuracy within specified limits, for at least one year.

Each year, a NIST thermometer must be recertified to assure accuracy. This is a service usually provided by the manufacturer of the thermometer or a NIST calibration laboratory.

Calibrated thermometer with certificate of traceability

Calibration is the process of standardizing a temperature monitoring instrument to ensure that it will measure within a specific temperature range in which the instrument is designed to operate. The accuracy of a thermometer is its ability to measure temperature correctly without error.

A thermometer must be within ±2°F (±0.5°C) of the actual temperature to be considered an accurate device. A thermometer’s ability to detect subtle changes in temperature is its sensitivity. For example, a bi-metal coil thermometer can detect a 1.0-degree temperature change, while a thermistor may detect a 0.1-degree temperature change.

It is recommended that process or product temperature monitoring equipment be calibrated daily, before use. New equipment must be calibrated upon receipt and before putting it into service.

Also, thermometers that have been dropped on the floor or used frequently must be calibrated more often. Depending on the instrument and intended temperature use range, an ice water method and boiling water method, when used properly, are effective calibration methods.

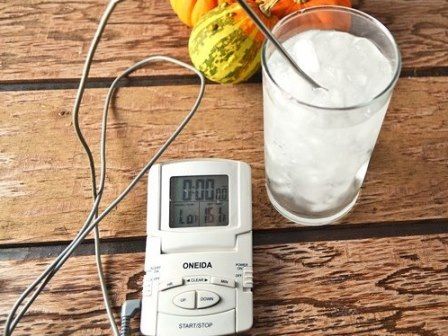

Thermometer calibration equipment

Another technique is to use sophisticated calibration equipment available from manufacturers. These units are designed to calibrate several thermometers at one time within a specific temperature range. Many of these units are able to interface with a computer to assist with record keeping. The calibration method used at your facility depends on the temperature monitoring instrument, monitoring frequency, and intended use, and whether for a product or environmental monitoring.

Other acceptable methods may also be used to calibrate temperature monitoring instruments.

Thermometer calibration methods

Calibration methods are presented for the following temperature monitoring instruments: bi-metal coil thermometer, thermocouple thermometer, and thermistor thermometer. Calibration of non-product contact thermometers such as Resistance Temperature Detector (RTD), oven temperature recording devices, and infrared thermometers are also described. A major consideration when using any thermometer is the consistency of the product and temperature distribution throughout the product.

For instance, to measure the internal temperature of a hamburger patty 1⁄8 inch (3 mm) thick would require using an instrument having a thin probe that can detect temperature quickly and accurately. Measuring the internal temperature of a bone-in ham could be done adequately using a thick probe having a 2- to 3-inch (5.1 to 7.6 cm) temperature sensing region. The product type or the environment to be monitored will influence the selection of the most effective temperature monitoring instrument to use.

Reference Thermometers

Laboratory and industry supply catalogs market NIST reference thermometers. Local county extension agents or high school science teachers may have these catalogs. A temperature monitoring device such as a mercury-in-glass thermometer or a thermistor can be used as a reference thermometer as long as the device is NIST certified and the annual calibration and certification are maintained through a NIST laboratory.

Bi-metal Coil Thermometer

Common types of bi-metal coil thermometers are dial and instant-read digital thermometers. Contained within the stem of the thermometer is a coil made of two different metals bonded together to a temperature indicator. This type of thermometer detects temperatures from the tip of the stem to a point 2 to 2 1⁄2 inches (5.1 to 6.4 cm) above the tip. An indentation in the stem indicates the area of the stem that is the temperature sensing region.

The temperature indicated on the dial is an average of temperatures along this region. These thermometers must be inserted 2 to 3 inches (5.1 to 7.6 cm) into the geometric center of a product.

Extreme fluctuation in temperature along the sensing region can affect the extension of the bi-metal coil, which affects thermometer accuracy. Bi-metal thermometers are sensitive to physical stress such as torque on the stem, or shock from dropping on the floor. These stresses can affect the tension of the bimetal coil, which necessitates calibration of the thermometer before reuse.

Calibration of thermometer procedure

Bi-metal coil thermometer calibration method

Calibration for use in hot processes and products (boiling water method):

The items needed for calibrating thermometers used in hot processes are:

• One pint (500 ml) PyrexTM or heat tolerant container

• Distilled water

• Heat source such as a hot plate

• NIST reference thermometer

Once these supplies are assembled, the following steps are used to calibrate bi-metal coil thermometers for use in hot processes.

Thermometer calibration procedure

- Heat distilled water to a specific reference temperature. This reference temperature can be 212°F (100°C)—described as a rolling boil at sea level altitude. The boiling point of water changes with altitude. To find the correct boiling point for your area, refer to Figure 1, Boiling point of water with relationship to altitude. An alternative reference temperature for example is the target end temperature of a product.

Specifically, if the intended use of the thermometer is to measure the final internal temperature of a cooked uncured turkey roll at the end of thermal processing, then a target temperature of 160°F (71°C) should be used for the reference temperature. - Once the distilled water has reached the reference temperature, place the thermometer to be calibrated in the hot water bath. Immerse the stem to a minimum depth of 2 1⁄2 inches (6.4 cm). Place the NIST reference thermometer in the water bath at the same time, to the same depth, as the bimetal coil thermometer. Make sure that neither thermometer comes in direct contact with the bottom of the heated container or each other.

- After one minute, compare the bi-metal coil thermometer reading to the NIST reference thermometer. Record the readings of the two instruments on a record-keeping form such as a thermometer calibration log.

Thermometer calibration guide

- Correct the indicator needle of the bi-metal coil thermometer. Adjust the spring on the coil by turning the hex nut directly behind the faceplate of the thermometer. Digital instant-read thermometers may have a calibration button to adjust the temperature reading. If the thermometer cannot be physically calibrated and the accuracy of the unit is more than ±2°F (±0.5°C) then the unit should not be used. Contact the thermometer manufacturer for further instructions.

- Recheck the temperature reading on the bimetal coil thermometer after making any adjustments. This is accomplished by repeating steps 1 through 3. The calibration adjustment should be noted in the thermometer calibration log.

- Once a bi-metal coil thermometer has been calibrated for high-temperature use, label the thermometer for use in this temperature range. This can be done by electroplating or etching the thermometer on the back of the faceplate with a number or letter indicating the temperature range of its intended use.

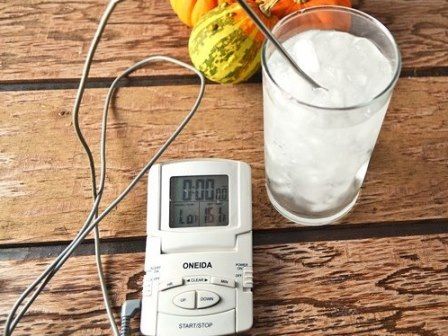

Ice point method

Thermometer calibration for use in cold process and products (ice water method)

An easy way to calibrate your thermometer is to put it in ice water and adjusting it to read

A similar calibration procedure can be used for thermometers intended to be used in cold processes and products.

Materials necessary to calibrate a thermometer for cold uses are:

• Sturdy 1 pint (500 ml) container,

• Distilled water

• Crushed ice

• NIST reference thermometer

The same NIST reference thermometer used for high temperature calibration can be used for low-temperature calibration as long as the thermometer is allowed to equilibrate to room temperature before use.

To calibrate a thermometer for low-temperature monitoring, follow these steps:

- Place crushed ice in a beaker or container, add just enough distilled water to make a uniform slush ice medium to facilitate even contact between thermometers and the slush ice bath.

- Place the NIST reference thermometer in the ice water bath. It is important to keep the tip of the thermometer immersed a minimum of 2 1⁄2 inches (6.4 cm) without touching the bottom of the container.

- The NIST reference thermometer should read 32°F (0°C) when placed in the slush ice bath. If the temperature is above 32°F (0°C), add more crushed ice to the beaker. If the reference thermometer is not equilibrating to 32°F (0°C) slush ice bath, start over with a clean beaker of crushed ice and distilled water. If this is still not working, check with the manufacturer of the NIST reference thermometer.

- Place the bi-metal coil thermometer in the ice water bath for at least one minute by immersing it to a minimum depth of 2 1⁄2 inches (6.4 cm).

- Be sure the tip does not touch the bottom of the container.

- Compare the reading of the bi-metal coil thermometer to the NIST reference thermometer.

- Adjust and recheck the bimetal coil thermometer as described for the boiling point method.

- If the thermometer cannot be physically calibrated and the accuracy of the unit is more than ±2°F (±0.5°C), then the thermometer should not be used. Contact the thermometer manufacturer for further instructions.

- Note calibration adjustment in the thermometer calibration log and label the thermometer for use in low-temperature ranges.

- This can be done by electroplating or etching the thermometer on the back of the faceplate with a number or letter indicating the temperature range of its intended use.

What is a nist thermometer?

An NIST certification can be a NIST Certificate of Calibration, meaning that the thermometer was tested to be within its stated tolerance of accuracy and if it was not, the thermometer is adjusted to be within that tolerance.

Remove the plastic lens using a small flathead screwdriver. To increase the temperature reading rotate the pointer clockwise. To decrease the temperature reading rotate the pointer counterclockwise. Repeat as many times as necessary before placing back in place.

How to calibrate a digital thermometer?

A digital thermometer should always return accurate readings. Whether you use it for measuring body temperature, atmospheric temperature, or any other relevant use.

An easy way to Calibrate your Thermometer

Now more than ever it’s important to learn how to calibrate a thermometer. Since we’re not all so lucky to own the world’s best and most accurate thermometer.

How to calibrate a digital thermometer?

A digital thermometer should always return accurate readings. Whether you use it for measuring body temperature, atmospheric temperature, or any other relevant use.

The most read

Infrared Thermometer made in USA

- What is Top 10 Thermometer Made In the USA in 2020?

- What is the best medical infrared thermometer made in the USA?

- What is the best-infrared thermometer made in the USA?