Temperature calibration equipment offers superior performance in terms of accuracy, stability, and uniformity. You can find temperature calibrators built specifically for industrial process environments.

Temperature is the most commonly measured parameter in commercial and industrial settings.

Maintaining the accuracy of temperature sensors, probes and transmitters requires periodic calibration using a dry block, blackbody source, liquid bath, fixed-point cell, multifunction calibrator, or other temperature calibrators.

There are specific benefits for each of these types of calibrators and each can offer precision calibrations to traceable standards.

What is a temperature calibrator?

Typically, a temperature calibrator is a device that can simulate temperature sensors or a device that sources temperature as a point of reference at a known level of uncertainty or accuracy that is compared to temperature readings of a temperature measuring device, such as a thermometer, of unknown accuracy.

Temperature calibration methods

A temperature calibrator can have different interpretations depending on the use.

One person’s app changes the way they would define a temperature calibrator. When some people think of a temperature calibrator, they are thinking of a handheld device that electronically simulates temperature sensors as if they were at a particular use temperature.

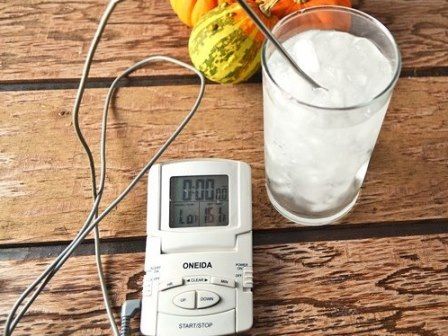

Others define a temperature calibrator as a heat source such as an ice bath or oven that has a calibrated display.

And another group of people will say that a temperature calibrator is a system of devices that are used to simulate or generate temperature.

Temperature calibration equipment

Regardless of the different ways people think of a temperature calibrator, the principle is the same, a temperature calibrator is an instrument used to determine if a temperature device is performing within specified limits of uncertainty or accuracy.

Common devices that are often referred to as a temperature calibrator include:

- Temperature simulator

- Temperature heat source

- Temperature indicator

- Temperature calibration system

- Thermometer Calibrator

- Thermocouple furnace

- Dry block calibrator

- Dry well calibrator

- Metrology well

- Temperature bath

- Infrared calibrator

- Temperature standard

- Fixed-point cell

- Temperature oven

Temperature calibration procedure

All temperature calibrators go through three results:

- Source temperature

- Temperature reading

- Temperature report

Source temperature

Two common ways to source temperature include simulation and producing physical heat.

- Simulated temperature: Temperature calibrators that use simulation are usually portable devices whose internal electronics can generate different levels of voltage or resistance to simulate temperature.

The voltage output signal represents a thermocouple at temperature and the resistance output signal is represented by a thermistor.

The simulator allows the user to choose which of the sensor types to simulate and at what temperature to simulate the sensor in operation.

Therefore, a simulator is used to verify that the reading from a sensor, such as a temperature transmitter or the oven display, correctly measures and displays the electrical output of a temperature sensor.

- Physical heat: Temperature calibrators that produce physical heat include dry block ovens, infrared radiation calibrators, temperature chambers, ovens, and temperature calibration baths.

These calibrators often have built-in sensors to measure and display the temperature of the calibrator.

However, when high precision or low uncertainty is required, it is common to insert a more accurate sensor, called an external reference probe.

Temperature reading

There are a few common ways that temperature calibrators read and report temperatures.

A common way is that the device that generates the temperature has an input to measure the sensor.

The temperature calibrator display shows its own temperature and the temperature of the device under test.

Another common way is to insert a sensor into the calibrator and the sensor remains connected to the display, transmitter, or reader that measures the sensor.

The displayed calibrator temperature is then compared to the display.

Temperature report

or greater precision and ease of use, some temperature calibrators are equipped with an interface that allows the user to connect a digital reference thermometer system that measures the temperature calibrator more accurately and can automatically communicate with the calibrator, to establish temperature points.

Portable temperature calibration equipment

Ensuring process temperature accuracy involves calibrating not only the system’s electronic temperature signals, but also the very temperature sensors that initiate those signals.

Portable temperature calibrators generate and measure temperature, power transmitters, and store data.

Temperature calibration equipment covers temperatures from -45 ° C to 1200 ° C and includes handheld, portable and benchtop calibrators.

Infrared thermometer calibrators and reference measurement thermometers ensure that all the necessary tools are available to you.

Portable temperature sensor simulators are smaller, easier to transport, and can often be battery powered. They are used for field work to test temperature sensor circuits such as transmitter systems, oven displays, and PLC systems and are generally optimized for this type of work.

There are more powerful versions than portable simulators. They have more software options and features designed for factory process calibration needs. Some of these can run automated test sequences, record results, control other test and calibration instruments, and connect to data systems commonly used in factories and industrial process control.

why equipment need calibration?

Calibration defines the precision and quality of the measurements recorded using a piece of equipment.

Over time, results and accuracy tend to “drift,” especially when technologies are used or parameters such as temperature and humidity are measured.

To have confidence in the results being measured, there is a constant need to maintain the calibration of the equipment throughout its useful life to obtain reliable, accurate and repeatable measurements.

The goal of calibration is to minimize any measurement uncertainty by ensuring the accuracy of the test equipment. Calibration quantifies and controls errors or uncertainties within the measurement processes to an acceptable level.

Why devices need calibration?

All devices used for critical process measurements should be periodically checked to verify that they continue to provide the required accuracy.

When adjustment is possible, a device that measures outside the expected limits should return to an acceptable level of performance, but in the case of non-adjustable equipment, the deviation or performance of the measurement should be recorded and a decision made as to whether. still fit for purpose.

A temperature calibrator is typically a product that includes a heat source or cooling, that can be controlled to the desired temperature.

To calibrate a temperature sensor, it must be inserted into a known temperature. Sensors are calibrated either by using temperature dry blocks for industrial fields or liquid baths in a laboratory.

Components, such as electronics, used in an instrument may be affected by changes in operating temperature. If an instrument is calibrated at one temperature and then operated at a significantly different temperature, the temperature-induced error can also degrade the results’ accuracy.

Infrared Thermometer Calibration

Regular thermometer calibration ensures that your device is operating at its highest possible level of accuracy.

How to calibrate a digital thermometer?

A digital thermometer should always return accurate readings. Whether you use it for measuring body temperature, atmospheric temperature, or any other relevant use.

An easy way to Calibrate your Thermometer

Now more than ever it’s important to learn how to calibrate a thermometer. Since we’re not all so lucky to own the world’s best and most accurate thermometer.

NIST Thermometer Calibration

Temperature is a critical measurement for ensuring the safety and quality of many food products. There are a variety of commercial temperature monitoring devices available.

Portable Temperature Calibration Equipment

Typically, a temperature calibrator is a portable device that can simulate temperature sensors.