-Thermometer Calibration Guide

-Temperature sensor calibration procedure

-Thermometers Calibration Procedure:

Calibrating your thermometer is quick and easy. Many analog and digital thermometers allow you to offset the temperature to adjust for the calibrated value. However, if your thermometer doesn’t offer an offset function, a piece of blue tape with the delta will work just fine.

The product type or the environment to be monitored will influence the selection of the most effective temperature monitoring instrument to use.

Thermometers calibration procedure

The thermodynamics of thermocouple temperature measurement is much different from bi-metal coil thermometers. A thermocouple measures the voltage potential difference between two dissimilar metals having different thermal conductivity, joined at one junction.

Thermocouple Thermometer

When heated, each metal releases an electrical current different from the other. The temperature reading is a function of the junction between the two metals, the composition of the metals, and the voltmeter measuring the current. Although calibration is possible there are many other facets to consider. There are electrical components in the digital display and the probe must be in good mechanical condition.

Consider using a commercial calibration service provided by the thermocouple manufacturer or from a NIST calibration laboratory. Voltage resolution, speed, and accuracy of the measurement and temperature range determine which thermocouple probe to use. Voltage resolution affects the thermocouple’s ability to detect small changes in temperature.

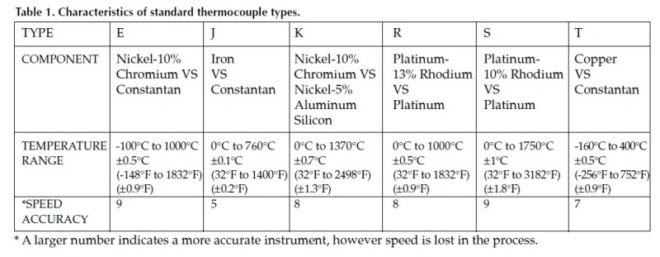

A common thermocouple type is “R,” which is a combination of platinum/13% rhodium adjacent to platinum having a temperature range from 0°C to 1000°C (32°F to 1832°F) that is accurate to within 0.5°C (0.5°F).

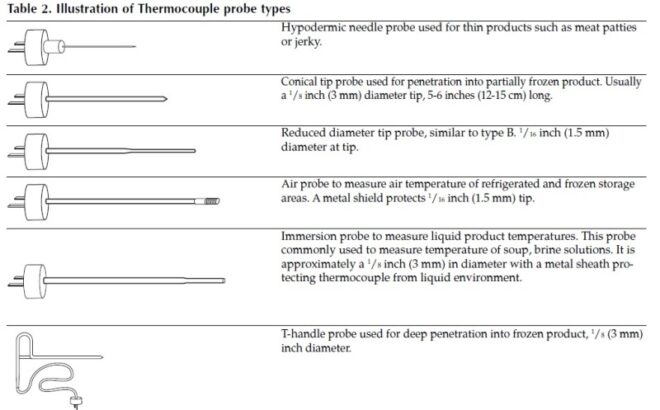

The characteristics of other standard probes are listed in Table 1. Any of the thermocouple types listed in Table 1 can be used for temperature measurement in meat and food processing environments. The most important consideration when choosing a thermocouple is selecting the appropriate probe or stainless steel sheath covering the thermocouple wire. For example, there are hypodermic probes, immersion probes, and penetrating probes, each used for a specific type of food (Table 2).

The cost of a thermocouple thermometer depends on the probe and the electronic component reading the voltage measurement.

Calibration procedure for thermocouple

Thermocouple thermometer calibration method:

The calibration methods used for bi-metal coil thermometers can be used for thermocouple thermometers. Some electronic units include a calibration mode, which does an internal circuitry calibration.

However, a thermocouple thermometer must be checked with external temperatures to ensure proper reading within a specified temperature range. As with any electronic equipment, check with the manufacturer for the proper method to calibrate the instrument.

Thermometers calibration procedure:

- Advantages of thermocouple thermometers

- Wide variety probes available over a wide temperature range

- Inexpensive

- The temperature sensed as the tip of the probe

- Disadvantages of thermocouple thermometers

- Requires internal reference

- Least stable and least sensitive

Thermistor calibration method

Thermistors are fragile and can lose calibration at extremely high temperatures. Because of the nature of the component metals, thermistors are not easy to calibrate. These instruments may have an internal calibration setting similar to a thermocouple thermometer.

Using the method described for bi-metal coil thermometers will indicate if the instrument is operating within a specified temperature. Check with the manufacturer for proper calibration methodology for thermistors. (Thermometers calibration procedure)

- Advantages of thermistor thermometers

- Highly sensitive

- Small, thin probe available

- Responds quickly to small temperature changes

- Tip of the probe senses temperature

- Disadvantages of thermistor thermometers

- Fragile

- Limited to a few hundred-degree temperature range

- Errors due to self-heating

Thermistor Thermometer

A thermistor is a generic term for “thermally sensitive resistors.” The keyword in this phrase is sensitive. Thermistor thermometers are the most sensitive temperature measuring devices, able to detect small changes in temperature.

Transitional metal oxides are semi-conductive materials used in thermistors. Manganese and nickel, or manganese, nickel, and cobalt are the most common component metals. Thermistors can be manufactured to fit any need and can be as small as 0.07 mm in diameter.

Thermistors can be used over a wide range of temperatures without affecting accuracy.

Non-product Contact Thermometers

Thermometers used to monitor room temperature, cooler and refrigerator temperatures are essential in maintaining high-quality products.

Depending on the HACCP plan, storage room temperature may be a critical control point for the uncooked refrigerated products. Environmental conditions, especially relative humidity affect heat transfer in large coolers. This is an important consideration during the summer months. Therefore, thermometers used to monitor room temperature must be routinely checked for calibration.

Resistance Temperature Detector

A resistance temperature detector (RTD) is a thin platinum wire wrapped around a glass or ceramic rod.

Platinum wire coils can also be embedded in a ceramic matrix. A protective coating of glass or ceramic completely houses the detector. The accuracy of temperature readings for an RTD should be compared to a NIST reference thermometer at least monthly depending on use in the facility and type of device. The RTD device is stable and accurate, however, it is fragile and not easy to calibrate. Once an RTD falters it is best to replace it. Remember to keep current records of all readings when taken and note temperature differential.

- Advantages of RTD

- Stable

- Accurate

- Disadvantages of RTD

- Expensive

- Self-heating

- Difficult to calibrate

Thermometer calibration guide

Infrared Thermometer

An infrared (IR) thermometer is a device that collects radiant infrared energy emitted from an object. The detector converts the energy signal to a temperature reading. Most IR thermometers respond within 0.5 seconds and have 100 feet (30.5 m) maximum measuring distance, depending on the environmental conditions. The ability of an object to release or absorb energy is called emissivity.

IR thermometers are affected by an emissivity, which is complicated by shiny surfaces. Most IR units can be adjusted for emissivity by comparing the IR thermometer surface temperature of an object to a reference thermometer temperature reading of the same surface. The IR thermometer can then be adjusted to the reference temperature.

- Advantages of IR thermometers

- Fast, accurate

- Surface temperature measurement

- Non-destructive, non-contact measurement

- Disadvantages of IR thermometers

- Surface emissivity affects accuracy

- Environmental conditions, such as relative humidity affect the accuracy

IR thermometer calibration method

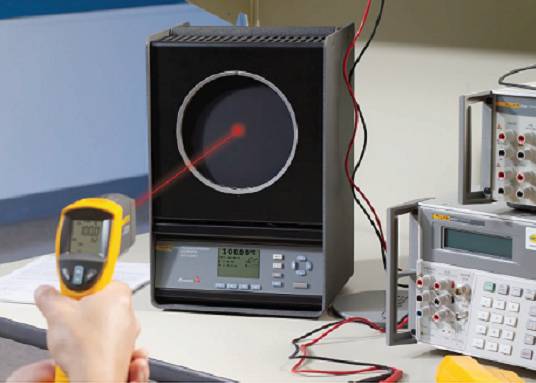

IR thermometers are calibrated using a “Blackbody,” which emits a given amount of energy at a given temperature. A blackbody calibration instrument is expensive. However, most manufacturers of NIST IR thermometers provide a calibration service for a nominal fee for yearly calibration and certification.

Smokehouse thermistor probe

Smokehouse Temperature Recording Device – Batch or continuous ovens (smokehouse) use either thermocouples or RTD to monitor oven temperature during thermal processing.

The oven temperature must be continuously recorded by a chart recorder. Several electrical components involved in this process must be checked weekly and calibrated monthly by a certified technician or by the equipment manufacturer service technician. The accuracy of the probes can be checked by placing them into 140° to 180°F (60 to 82°C) hot water and comparing the temperature reading to a certified NIST reference thermometer. Record keeping is essential to track trends and any possible drift in temperature measurement.

Record Keeping

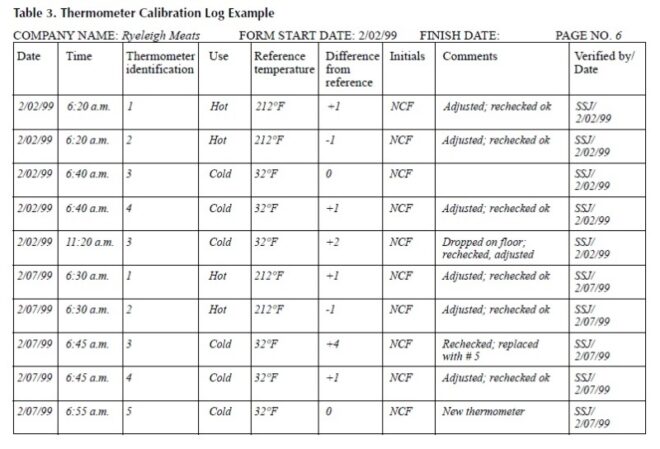

Record keeping is an essential component of any calibration program. To simplify record keeping, each thermometer should be marked with a permanent identification number or code.

At a minimum, the following information should be included in a calibration record: thermometer identification, date, time, intended use (hot/cold product or process), temperature reading difference from reference, and initials of person testing equipment.

Table 3 illustrates the use of a thermometer calibration log while a blank form is provided in Table 4. A thermometer should be replaced when a temperature difference or drift is consistently greater than ±2°F (±0.5°C). When a thermometer is replaced, a note should be made on the log and a new label assigned to the replacement thermometer.

How to calibrate a thermometer?

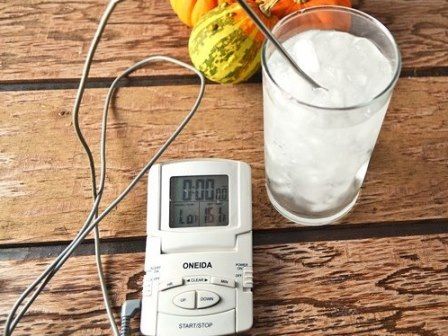

Thermometers should be calibrated regularly to make sure the readings are correct. The ice-point method is the most widely used method to calibrate a thermometer.

Fill a glass with crushed ice and add cold water until the glass is full. Insert thermometer probe in the center of the glass of ice water, not touching the thermometer to the bottom or sides of the glass. Stir slightly, then wait until the temperature indicator on the thermometer is stabilized.

The ice point method is the most widely used method to calibrate a thermometer in addition to the boiling water method.

How to calibrate a digital thermometer?

A digital thermometer should always return accurate readings. Whether you use it for measuring body temperature, atmospheric temperature, or any other relevant use.

NIST Thermometer Calibration

Temperature is a critical measurement for ensuring the safety and quality of many food products. There are a variety of commercial temperature monitoring devices available.

Infrared Thermometer Calibration

Regular thermometer calibration ensures that your device is operating at its highest possible level of accuracy.

An easy way to Calibrate your Thermometer

Now more than ever it’s important to learn how to calibrate a thermometer. Since we’re not all so lucky to own the world’s best and most accurate thermometer.

The most read

Infrared Thermometer for Office made in USA

- What are the Top 10 Thermometers Made In the USA in 2021?

- What is the best-infrared thermometer made in the USA?