Cranes lift and lower loads with a hoist that is attached to a trolley. The trolley moves back and forth along a bridge. The bridge moves along a runway.

Some cranes, such as a jib crane, don’t have a bridge but still have a hoist attached to a trolley and can move a load in a horizontal direction.

A bridge crane is defined as a crane, fixed or able to move along a track(s) having at least one primarily horizontal girder and equipped with at least one hoisting mechanism. There are four main types of overhead cranes: top running, under running, single girder, and double girder.

Hoist crane components

A variety of OEM parts and components are available for overhead cranes and hoists.

Brands of wire rope hoists, electric hoists, manual chain hoists, gantry cranes, jib cranes, work station cranes and bridge crane equipment; they have the same accessories and components.

Thousands of parts are available, including replacement hangers, motors, brake pads, hoist chain, replacement hooks, latch kits, and capacitors. Visit the specialized web pages to review hoist parts and for more information on the parts that are available.

Bridge crane components

Components can be individually designed to suit different requirements. All products and components are designed, developed and manufactured in compliance with design standards and regulations.

Overhead crane components follow the latest innovations in the field of crane construction using years of experience and knowledge from partners around the world.

Overhead crane parts and functions

- The Bridge

- End Trucks

- Girders

- Trolley Hoist

- Trolley

- Hoist

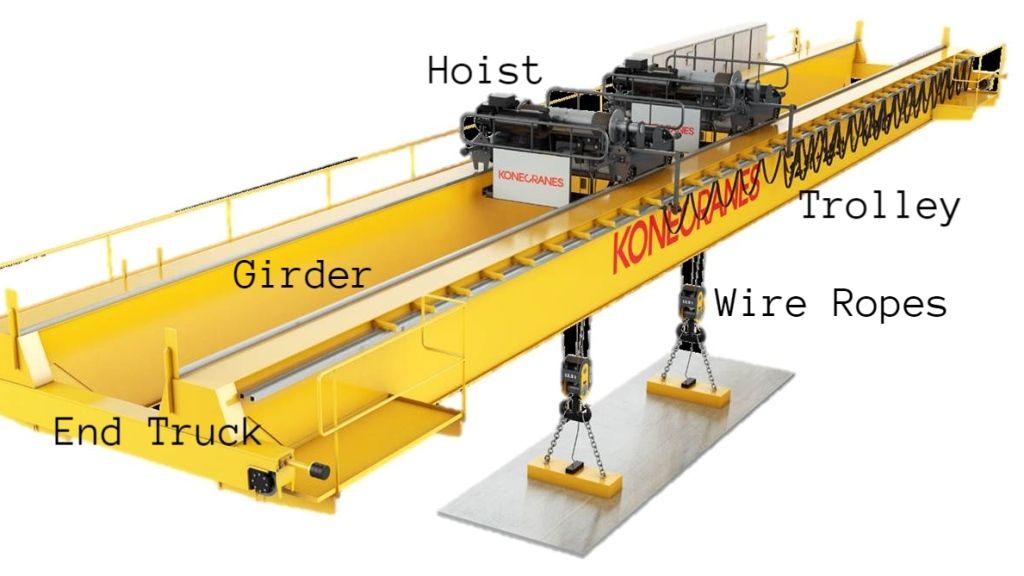

The Bridge: The bridge is made up of a single girder or a double girder with a set of carriages at both ends. The bridge spans the width of your facility and this mobile section is the main support structure of your bridge crane.

End Trucks: Bridge crane heads are positioned on both sides, where the bridge wheel assemblies are housed. This allows the entire crane to travel along the entire structure. The wheel assemblies of the bridge end run along rails that are mounted on the beams.

Girders: The crane beams are connected to the end trucks and are the structure on which the truck is supported. The girders are the horizontal beams and are considered a main element of the overhead crane system.

Trolley Hoist: This component is a combination of the hoist and the trolley frame. In double hoist applications, two hoists can be mounted on a single frame or two frames can be built, each with separate hoists.

Trolley: The bridge crane trolley rides across the span of the bridge along the girder or girders and carries the hoist.

Hoist: The hoist is designed to lift and lower the desired load and is attached to the trolley frame by a custom lifting hook to support the load. You have a choice of two chain or wire rope hoist models.

Wire rope hoists are safe, reliable, durable and designed for years of long-term use. Chain hoists, on the other hand, are designed for smaller capacity operations and are ideal for light duty requirements or new projects where price is an important factor when selecting lifting equipment.

The most Read

Overhead Crane Parts

Overhead crane equipment parts can be broken down into four main categories:

Overhead Crane Electrical Components

Traveling cranes require circuit breakers, transformers, variable frequency drives, and surge suppressors, among many other components.