Overhead Crane Lights: The crane spotlights are for companies that have fixed overhead cranes. It is the only light of its kind in the industry. Cranes operate in close proximity to people and in-plant vehicles and can pose a real danger to them if they get too close or if they are unaware of the crane’s presence.

Overhead Crane Lights:

Have you ever walked through a facility when suddenly a maintenance cart approached from behind without you being aware of it? Have you ever stepped around a blind corner and been startled by a piece of mobile equipment moving toward you?

Crane warning light

Everyone is busy these days, often multi-tasking and being in a hurry, which can distract an employee from serious hazards such as mobile equipment traffic.

Audible alarms are great but often serve as a general warning of equipment in the area.

If you also consider how loud a steel mill can be, along with the continuous use of mobile equipment or overhead crane sirens throughout a workday, you can understand how workers may become immune to these audible alarms.

To increase pedestrians’ awareness of mobile equipment movement, warning spotlights are being manufactured that will broadcast a spot on the floor 15 to 20 feet from the equipment to forewarn pedestrians of their approach.

In these years, began installing blue spotlights on an overhead crane and other mobile equipment operating within the mill to increase pedestrian awareness.

The lights do not take the place of audible alarms, but they provide an additional visual warning that is very direct with respect to the proximity of the hazard.

Overhead crane warning lights

Overhead Crane Lights: The front light is continuously on when the overhead crane is running, and the rear light is wired to activate when the equipment is placed in reverse. Recognizing the increased safety awareness and potential market, manufacturers are now creating various lights that can project a line on the floor to warn pedestrians of the dangerous area surrounding mobile equipment (i.e., forklifts, rotating equipment).

The positive employee feedback regarding the awareness of mobile equipment via the blue lights recently installed made us wonder if such a concept could be implemented on all overhead cranes.

Overhead crane audible alarm

Although a well-known rule of looking up and locating cranes while walking through a steel mill exists, an employee focused on a task or deep in thought may not be aware of the overhead crane siren.

The audible alarm serves more as a general caution to employees in the area but requires employees to identify the hazard and assess if its proximity is in their immediate danger zone or not.

The movement of light from an overhead crane will provide an actual and definitive warning to affected employees, those in the immediate area.

Also, unlike audible warning sirens, which are dependent on the crane operator to activate, the spotlights are automatically on when the equipment is energized, thus reducing human error.

Overhead crane safety warning light

Unlike the blue lights on forklifts where the beam is projected 15 feet, producing a consistent and visible blue spot on the ground, It should be recognized that the variable heights of overhead cranes may be more difficult to find the right LED light to produce a large, bright spot on the floor.

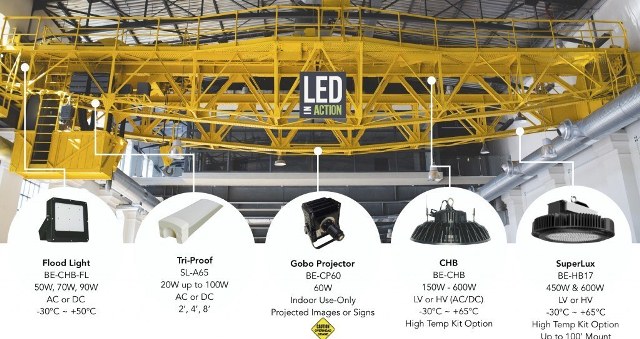

The options for overhead crane warning lights were investigated and it was discovered that this concept is still quite new, but manufacturers are designing and developing LED lights to be used in overhead cranes to warn pedestrians about the movement of the crane.

LED overhead crane lights

Overhead Crane Lights: The first LED lights trialed on overhead cranes were those used on mobile equipment — the 4 LED blue spotlight. The blue spotlight was installed on the bridge of an overhead crane at 65 feet and it created a 6-foot x 6-foot blue spot on the floor.

After installing the blue light on the crane we realized it would be best for the lights on overhead cranes to be different than the color of the lights used on the mobile equipment so that workers could distinguish between the two.

The only other color available in a focused beam spotlight was red. We purchased a red 4 LED spotlight from the same manufacturer as the mobile equipment light we already found success with and installed it on the same overhead crane at 65 feet.

Overhead crane safety lights

The crane’s area of operation was well-lit, with halogen lights and natural sunlight coming from overhead doors. However, this particular red light produced a soft red color spot, which was more difficult to see on the floor and tended to fade when exposed to full natural sunlight.

To overcome the height of our taller cranes (100 feet plus) and produce a stronger spotlight on the ground, we purchased red and blue 24 LED lights designed to be used on overhead cranes as warning lights.

These lights performed well from 100 feet, producing a bright 7-foot x 7-foot spot on the ground, but again, there was some fading of both the blue and red colors in areas illuminated by natural sunlight. ( Overhead Crane Lights )

Light duty overhead crane

After trialing a green light on a crane, we received quick feedback from our employees that they felt visibility was greater with the red light versus the green light. Considering the performance of the different colored lights and our employees’ feedback, It has been decided that the red light is better for the needs of industrial facilities.

Each installation interested in this technology, has to experiment with different types of colored lights in its facilities, to determine which light is best for your needs.

The overhead crane lights have been a positive complement to the audible warning siren. Should employees become distracted or complacent to the audible warnings of overhead cranes, a moving light on the floor will grab their attention and prevent them from unknowingly walking under a suspended load.

The lights will be angled out from the bridge of a crane to warn workers of an approaching crane, with adjustable distances selected based on the area.

Overhead crane warning systems

Another option we may consider is installing lights on the trolley projecting straight down from the four corners of the trolley, thus creating a danger zone around a suspended load.

Installing the lights on the trolley can also be beneficial to crane operators while they are picking up or setting a load down, as they do not have to take their eyes off the crane block or load to know the trolley is centered over the load.

Your effort to provide more awareness about the movement of the overhead crane will result in fewer opportunities for employees to be in the wrong place at the wrong time, minimizing the potential of an avoidable accident. ( Overhead Crane Lights )

How do security lights work in cranes?

Overhead warning lights also make positioning the crane hook and moving objects easier for crane operators, who can use the light as a point of reference for their hook position. Install the lens cover to switch the light beam from a dot to a line. Mounting brackets are adjustable so placement of the warning light is simple and easy. This single overhead warning light projects one dot or line.

Overhead Crane Lights

Lights ensure the safety of pedestrians by projecting safety lines on the floor. Those lines (displayed in a chosen color) inform all employees nearby about the moving load. When used by the crane operator they help the operator position the crane precisely.

The installation process of all lamps is equally straightforward. All you need to do is mount the lamp directly on the crane. The included adjustable mounting bracket up and down, makes it easy to position the lamp precisely where you want it.

Discover their main benefits:

-Versatility: the lamp is available in two colors (red, and blue) and can be used both indoors and outdoor. Thanks to that it’s easy to adjust it to your company’s requirements.

-Convenience: the use of lamps makes the work of crane operators much easier and safer and provides them higher control over the load.

-Efficiency: the lamp is an ideal solution especially for crowded areas in any workplace, increasing the safety of your employees around cranes and loading areas.

Project lines or points of light from an elevator on the floor to help prevent injuries to workers caused by crane hooks and suspended loads. Each light has 24 LEDs that emit a light beam on the floor to warn that there is an aerial crane hook in the area.

The most read

Overhead Cranes

What are the parts of an overhead crane? What is the purpose of an overhead crane? How much does an overhead crane cost?

Overhead Crane Risk Assessment

What happens when there are structural defects in an overhead crane?

Overhead Crane Safety Program

Safety for the Good Operation of the Overhead Crane.