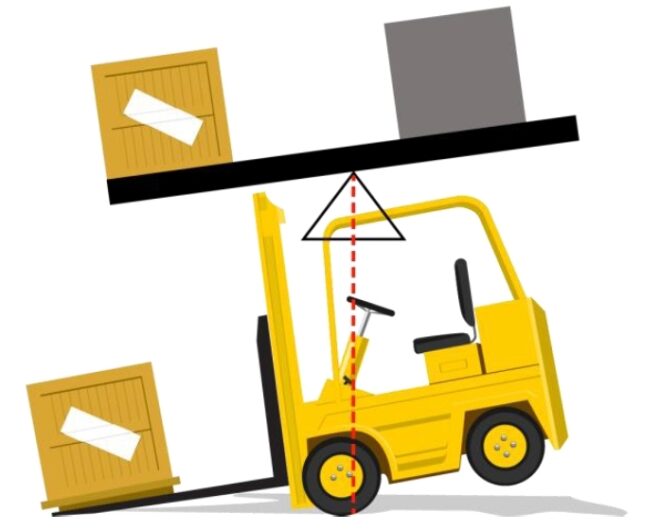

Forklift Stability Triangle: Making sure your forklift remains stable is one of the most important things you need to do while it’s in use. Unstable forklifts are the cause of many injuries and deaths each year when they fall on operators.

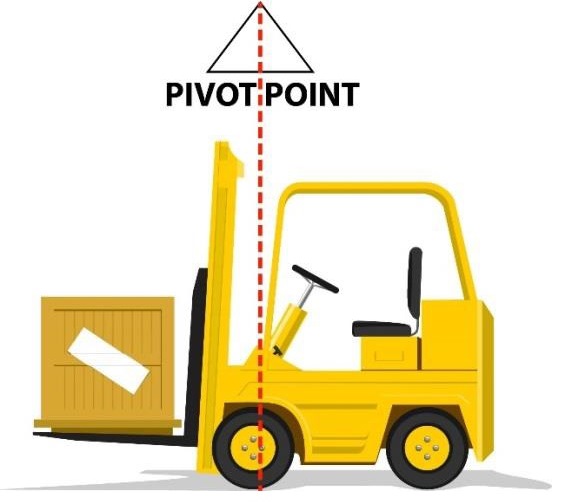

Forklift triangle of stability

Generally speaking, your forklift truck will stay stable as long as it’s properly loaded and is operated carefully by a professional driver. This is why it’s important that forklifts are not operated by anyone who doesn’t know what they’re doing and doesn’t understand what the truck can and can’t do.

Trucks themselves are very safe and secure when loaded and operated properly, and there’s no need to worry as long as you follow the appropriate rules and instructions. As a general rule, your truck’s stability will depend on its weight, height, speed, and distance. (Forklift Stability Triangle)

Average weight of a forklift

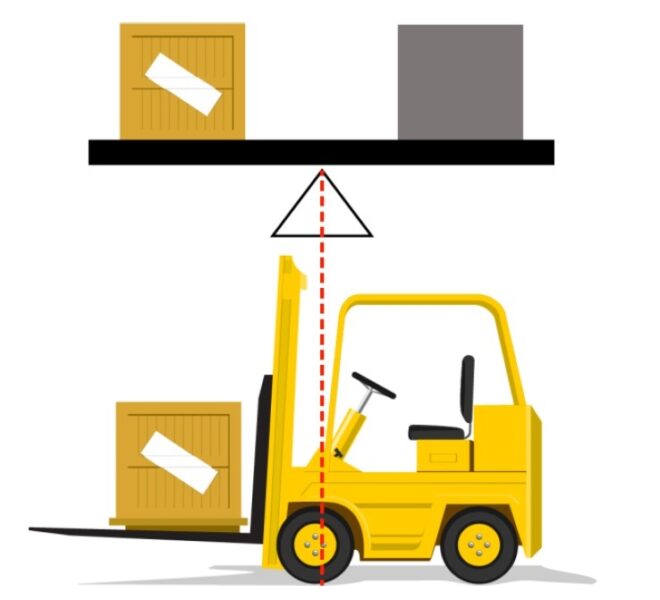

The weight of your truck is one of the main factors in determining its stability – Forklift Stability Triangle:

If you think of it as a seesaw, you will be able to understand that the back end of the truck must always be heavier than the load it carries. If the load should be the same weight or heavier than the truck itself, the truth is in danger of tipping over.

You can avoid this by always paying attention to the lifting capacity of the truck and ensuring you never exceed it. You can see the load center on the data plate which is fixed to your truck, and you can also see any differing load centers showing what you can lift and how.

Forklift lifting height

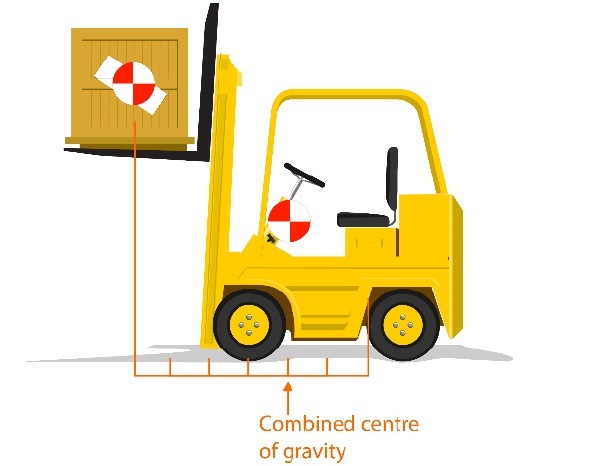

The height at which your load is raised affects the center of gravity and therefore the stability of your forklift.

Simply put, when you need to lift your load, you should move very carefully and aim to move only when you have to – mainly when loading or unloading, and not raising the load while driving.

Failure to observe this rule could lead to injury, broken goods, and other serious damage.

Forklift speed limit

No unnecessary speed should be used when operating your truck. While you need to drive efficiently, you should not be moving around at speeds which could cause your forklift to become unstable.

Speed affects the weight of your load, increasing it the faster you go. If you’re already carrying a heavy load, making it heavier will cause it to become unstable in exactly the same way as if you had overloaded it.

This can cause the truck to tip over, a danger which must be avoided.

Lateral instability forklift

Causes of truck instability –

Lateral instability forklift –

Forklift Stability Triangle:

Longitudinal (forward)

- Overloading

- Undercutting (not picking upload to the heel of forks)

- Tilting forward with the load raised

- Listing or raising the load while going downhill

- Braking too hard

- Traveling at fast or erratic speeds

Lateral (sideways)

- Turning too sharply

- Turning on slopes

- Turning sideways while lifting the load

- Driving over obstacles

- Driving over potholes

- Picking up a load while off-center

- Not using the side shift correctly

- Turning while the load is raised

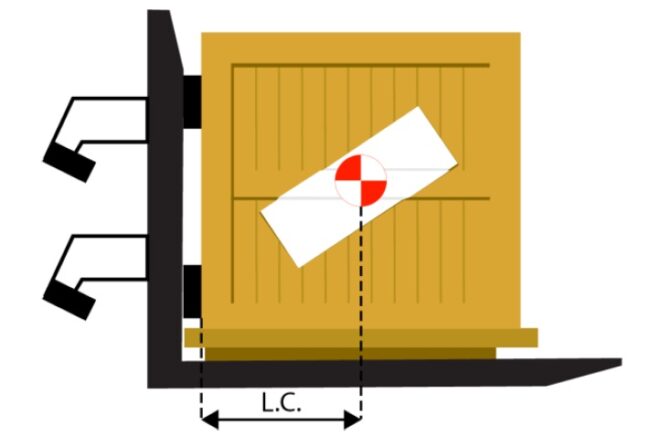

Load centre distance forklift

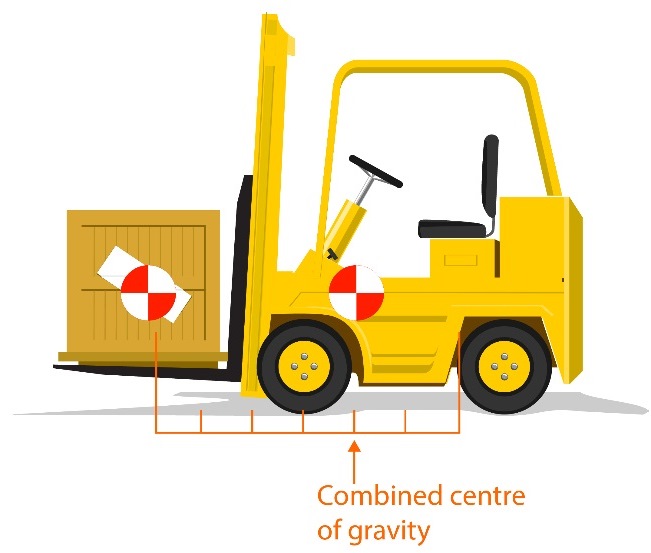

Distance (Load center) – Forklift Stability Triangle:

Distance is yet a further factor that could cause your forklift to tip over if safety rules are not properly observed.

If you bear in mind the seesaw analogy as previously mentioned, and the tipping effect it can have on your truck.

Taking a look at what happens when a load is moved away from the truck’s fulcrum (see diagram 6) you’ll see that it’s not been set by the carriage or the backrest of the truck.

You could then find the truck tipping over forwards, causing breakages and expensive damage, so always pay attention to the distance.

Forklift Stability Triangle – If your truck tips:

Should your truck tip at all, you must follow the right safety procedures. This means staying in the truck, holding on tight, bracing your feet and leaning away from the point of impact. Trying to jump out of the truck could cause you to be put in even greater danger.

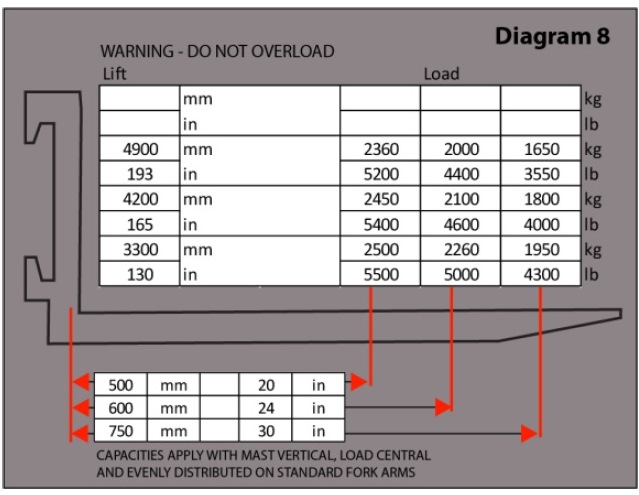

Forklift data plate explained

Load center – Forklift Stability Triangle:

Always check your data plate for the information about the distance from the heel to the back of the forks outwards to the center of gravity.

You can also see on some forklifts how much you can lift and at what load centers.

Remember that the weight of the load indicated on the truck’s capacity plate is MAXIMUM. It must NEVER be exceeded and in some applications the actual load handled should be considerably less.

Forklift on road requirements

The following are some general rules you should always follow in order to safely operate a forklift.

- Only operate vehicles you are trained and authorized to operate

- Read the manufacturer’s instructions thoroughly before you attempt to operate any vehicle

- Carry out thorough and proper safety checks every time you use the vehicle

- If you feel tired or unwell, or you have been drinking or taking medication, do not drive any vehicle

- If you need glasses to drive, make sure you don’t operate a vehicle without them

- Wear hard hats and any other appropriate safety equipment you need

- Always wear a seat belt

- Familiarise yourself with the signs and road markings wherever you’re working

- Note any height restrictions for your vehicle in the place you’re working

- Give clear and timely signals to other people working in your area

- Observe other people’s signals too

- Check your way is clear before you move off

Forklift rules and regulations

- Drive on the left wherever you can, unless it’s safer to drive in the middle for better visibility

- Slow down at junctions or crossings and sound your horn several times

- Take care to avoid pedestrians no matter who has right of way

- Drive at an appropriate speed and with due caution

- Make sure nobody is underneath your forks at any time

- Do not allow anyone to mount your forks at any time

- Take care to look out for any objects in your way

- Keep a safe distance from any other vehicles

- In case of a tall load blocking your view, drive backward while looking where you’re going

- If a load is in danger of collapsing, leave and tell a supervisor before trying to de-stack it

- Always keep your head and limbs inside the truck when driving

- Drive at a safe speed ensuring you have time for emergency stops if needed

- Observe ground surfaces to check whether they may be unsuitable for your truck

- Drive with loads as close to the ground as possible

- If you’re not carrying a load, raise your forks clear of the ground while driving

Forklift operator key responsibilities

- If driving outside without a load, always tilt your forks back

- Tilt your forks back when carrying a load

- If you can’t see properly when going up a slope, ask for assistance

- When going downhill without a load, the forks should face down

- Carry the load facing upwards if you need to go up a slope. When no load is carried, the forks should be downhill.

- Tilt the forks backward and raise them above the ground when on a slope

- Stick to a safe speed when on a slope

- Never turn when on a slope

- Drive at a 45-degree angle across bumps, railway lines, sleeping policemen, etc.

- Never stack while on a slope

- Never leave a forklift unattended on a slope

- If you need to leave a forklift on a slope in an emergency, the wheels should be wedged securely

- Always check the load weight, weight limit, and load center before picking up a load

- If you’re in danger of exceeding any limits, reduce the weight or get a forklift with a larger weight capacity

- Enter the load from the wide side wherever possible

- Insert and space the forks properly for the particular load width and type

- Take extra care if the tips of the forks

The load size, position, and weight distribution critically affect the forklift’s capacity and the stability of the truck. Consider the following factors before engaging a load:

-Weight, Size, and Position

-Safe Load Capacity

-Maximum Load Moment

-Balance

-Stability.

The most read

Forklift Brands

FORKLIFT BRANDS: Which forklift brand is best? top: Caterpillar, Toyota, Volvo, Hyundai, forklift brands and models, top 10 forklift brands, list

Stand-up Forklift

Stand-up forklifts (also known as stand-on and electric riders) are designed for applications where the operator must get on and off the lift truck frequently. They are more maneuverable and need less space to operate than sit-down forklifts.