The capacity rating plate on the forklift truck must be corrected when attachments are installed. This is called derating the lifting capacity. This is a rules and regulations mandate.

Looking for the Formula to rate the capacity on Forklifts.

Forklift lifting capacity

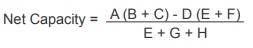

The calculation formula is provided below. It is the forklift owner’s responsibility to contact their forklift truck manufacturer/distributor with this information to obtain a new capacity rating on the forklift’s nameplate.

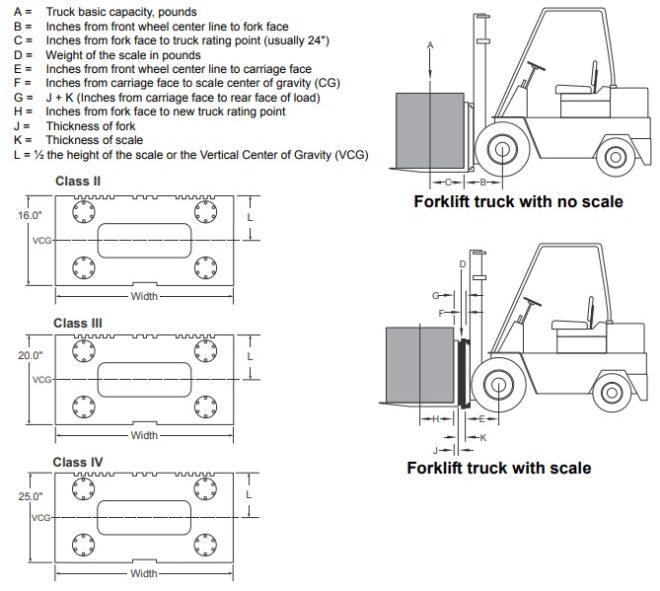

- The FLSC forklift scale comes in an ITA Class II (16” high, 5,000 lb/2,500 kg) model.

- The QTLTSC forklift truck scale comes in ITA Class II (16” high, 5,000 lb/2,500 kg) and

- ITA Class III (20” high, 5,000 lb/2,500 kg and 10,000 lb/5,000 kg) and

- Class IV (25” high, 10,000 lb and 16,000 lb) models.

Each class comes in several widths for cleat type carriages. Measure the height and width of the forklift truck carriage. Select from the tables in this document, the appropriate width that best meets the dimensions of the forklift truck carriage.

Use the weights, dimensions and the following formula to calculate the net lifting capacity of your forklift truck with a scale attached. Refer to the illustrations.

Forklift lifting capacity calculator

The calculator that is used to decide on forklift load capacity was designed with the average individual in mind. The reason for this is easy and this is because the addition of attachments to a forklift carriage creates an entirely new dynamic to the stability of the lift and will change the carrying capacity. There is actually a very complicated interrelationship going on with a multitude of forklift parameters which is often too detailed for the average person to comprehend.

Deciding on forklift load capacity is critical because there are several issues that can impact residual capacity. Included among these are forklift model, tires, mast, carriage, side-shift distance, rotational torque, horizontal load center, vertical load center, attachment specifications, fork specifications, many others, which the calculator takes into deliberation.

Rated capacity forklift

Specifications are affected by the condition of the vehicle and how it is equipped, as well as the nature and condition of the operating area. Inform your dealer of the nature and condition of the intended operating area when purchasing your Truck.

Care must be exercised when handling elevated loads. When the carriage and/or load is elevated, truck stability is reduced. It is

important that the mast tilt in either direction is kept to a minimum when loads are elevated.

Operators must be trained and must read, understand and follow the instructions contained in the Operating Manual. All values are nominal values and they are subject to tolerances. For further information, please contact the manufacturer.

- Weights are based on the following specifications: Complete truck with cab, pneumatic tires, mast, carriage, and forks.

- Unladen with new tires

- Bottom of forks n +/- 3% tolerance depend on tire inflated pressure or tire brand.

- Full suspension seat in the depressed position.

- Add 50 mm with load backrest

- Optional equipment

- Stacking aisle width is based on the VDI standard calculation as shown on the illustration. The British Industrial Truck Association recommends the addition of 100 mm to the total clearance (dimension a) for extra operating margin at the rear of the truck.

- Distance center truck to the centre of the internal turning radius.

- Travel speed laden/unladen limited at 25 km/h as factory default.

- Gradeability figures are provided for comparison of tractive performance but are not intended to endorse the operation of the vehicle on the stated inclines. Follow instructions in the operating manual regarding the operation on inclines.

- Engine data based on low mount exhaust.

- Data available on request, as values are dependent on application.

Forklift load centre calculator

Safely operating a powered industrial truck, or forklift requires the driver to be cognizant of how much weight is loaded on the forks.

Each machine has a load capacity rating that limits the amount of weight the forklift can carry, which often changes depending on the size, shape, and position of the load on the forks. However, these measurements can be made in the field through simple calculations.

Calculate forklift capacity height

Consider the size, shape, position and weight distribution of the load to determine if the machine can make the lift. Forklift manufacturers frequently calculate load capacity by measuring with an evenly distributed, square object at a 24-inch horizontal distance from the mast.

However, the majority of loads are not palletized squares or cubes, and the size or shape of the load may reduce the capacity. If the machine becomes overloaded, it could tip over, raise the rear wheels and affect steering control or cause the load to fall off the forks, resulting in property damage, injury or even death.

Prevent exceeding the machine’s load capacity by always reading the instructions on the forklift data plate or nameplate. Minimize the load distance from the front wheels to the load center by placing the load close to the front wheels.

The U.S. Department of Labor’s Occupational Safety and Health Administration (OSHA) also recommends arranging the heaviest part of the load closest to the mast.

It is easily calculated by measuring the load to be carried, and dividing by two (providing the load is evenly distributed, and positioned to butt up to the forklift backrest). You will often see a forklift truck’s nominal capacity quoted in a form such as 2,000kg @ 500mm load center.

The load center is the distance from the face of the forks to the load’s center of gravity. Many forklifts are rated using a 24-inch load center, which means that the load’s center of gravity must be 24 inches or less from the face of the forks.

The most read

Forklift Safety Procedures

Forklifts are extremely useful workplace vehicles, as long as they are used safely and appropriately by operators who are appropriately trained and competent to use them.

How to operate a stand-up forklift?

Two main ways of operating a forklift exist. Operating while sitting down, and operating while standing up.