A surge tank in hydro-power plants can provide a fundamental feature for the hydraulic design of hydropower projects.

Mainly, they can mitigate the effects of overpressure or water hammer and allow the turbine gates to close faster, reducing generator Overspeed after load shedding.

However, in normal operation, they also have the potential to be detrimental to the control systems of hydroelectric projects.

In reaction to hydraulic turbines, there are several ways to mitigate the magnitude of overpressure or water hammer situations.

For example, fast-acting pressure relief valves such as ring valves have been used.

In addition to the fast-closing of the gates, the magnitude of the pressure is a function of the length of the waterline. In short, the faster the closure and the longer the duct, the greater the overpressure.

Hydro Turbine generator

Water lines to drive turbines are generally not subject to the need for water hammer protection.

This is because they are typically designed with jet deflectors that are weighted to drop between the water jet and the runner buckets, allowing the nozzle valve to close slowly without creating undue pressure or allowing significant Overspeed of the nozzle. the turbine-generator.

Surge tanks (video) are the most common means of protection against excessive water hammer pressure.

These are vertical columns of water with the surface of the water exposed to the atmosphere. They are generally used in the penstock upstream of the turbine, but as close to the turbine as circumstances allow.

If the top of the tank is closed to the atmosphere to create a compensation chamber, these are called accumulators, but they are rarely used in hydroelectric power designs.

How does a surge tank work?

Surge tanks have the advantage of having no moving parts and therefore provide passive protection that is always ready to go.

In fact, they act in two different passive ways. When a positive pressure wave reaches the tank surface, it is reflected back down the duct as a negative wave.

This cancels out the next positive pressure wave to come. Similarly, the surge tank water surface reflects a smaller negative wave downstream, but enough to cancel part of the peak of the next positive pressure wave.

At the same time, part of the flow velocity that is reduced by the reduced opening between the bypass gates is diverted to the surge tank and does not contribute to the overpressure.

This causes the elevation of the water surface in the surge tank to increase dramatically.

However, this increase is not only due to the deviation, but part is due to the recovery of the velocity and the head loss in the pipe.

Once these hydraulic oscillations have been instituted in the surge tank, they can continue until they are dampened by hydraulic losses inside and outside the tank.

Water turbine generator

Hydroelectric power is a relatively new invention, but the mechanical energy of water has been used for more than two millennia. The invention of the wheel was soon followed by the invention of the waterwheel, a device that uses the downward movement of streams, rivers, and other bodies of water to mechanically power another device.

The oldest known version of the water wheel comes from Mesopotamia in the mid-4th century BC. C., a horizontal contraption similar to a propeller that was used to turn millstones to grind flour.

The basic waterwheel mechanism spread throughout much of the Old World (Eurasia and Africa) and took several different forms, but the core concept remained the same. As the watermill was further refined, its energy efficiency increased.

Understanding hydraulics was essential to the development of modern hydroelectricity because when the electrical generator was developed in the late 19th century, it could be combined with hydraulics to generate hydroelectricity.

The earliest hydraulic turbines had a vertical axis and used hydrostatic pressure to expel water from a nozzle, creating a rotational force. In many ways, it served as a prototype for modern hydraulic turbines.

The Industrial Revolution accelerated the evolution toward hydroelectric power as water mills gradually became water turbines.

Generator in hydro power plant

In the mid-19th century, turbine research led to energy efficiencies of over 75% (compared to early waterwheels, which were only 20% efficient). In 1850 the design of the water turbine was improved and achieved an efficiency of 90%.

Its high-efficiency turbines could match the unique flow conditions of individual water bodies. To this day, it remains the most widely used working turbine.

In 1832 the first electric generator was developed. Although the device, called a Faraday disk, was actually inefficient as a generator, it marked an important step in the development of electrical power. The concept behind electrical generators underwent experimentation, adjustment, and refinement throughout the 19th century, culminating in the invention of the modern DC dynamo.

Towards the end of the 19th century, hydroelectric power emerged as the preferred source of electrical power in the US, as the country had many rivers and hydroelectricity was cheap and reliable.

The rest of the world soon caught up, and by 1900, hundreds of small hydroelectric plants were in an operation spread across Europe, Asia, Australia, and South America.

Surge Tank in Hydroelectric Power Plant

A surge tank is a water storage device that is used in a hydroelectric power plant, to cushion the variation of excess pressure.

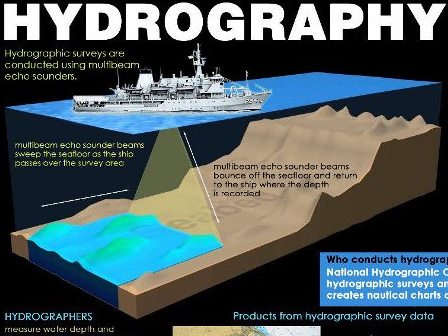

Bathymetric Survey

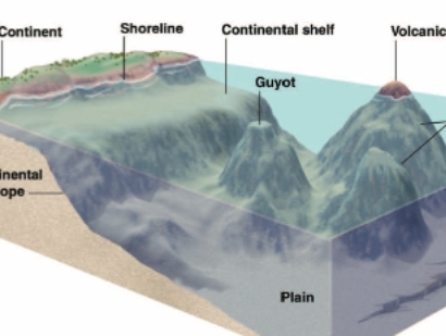

The variation in relief constitutes the morphology of the ocean floor. Charting of the ocean is very important for many reasons.

Underwater Topography Maps

Detailed depth contours provide the size, shape, and distribution of underwater features. The map serves as a tool for performing scientific, engineering, marine geophysical, and environmental studies.

Topographic Survey Cost

As a home or property owner, you may need to inspect your land. What is the cost of the topographic survey?