Tower crane anti-collision system: In worksite, multiple tower cranes are now working within one building or one construction site. The collision between the tower cranes, nearby structures, trees, or other towers often happens, which in turn damages the crane/other structures, resulting in heavy losses, sometimes stalling the project.

Anti collision system for cranes

After a year-long market study, it has been seen that most of the tower cranes do not have anti-collision systems. Even the Safe Load Indicator (SLI) is not installed. Some tower cranes have safe load indicators but are unable to link with the anti-collision systems.

Multiple monitors/displays in the operator’s cabin also confuse the operator and lead to accidents. Frequent power failure at construction sites adds problems like improper shutdown, data corruption, non-detection of radio signals, restart, etc.

Anti collision device for cranes

After studying all these problems, an anti-collision system has been developed with built-in SLI and wind velocity control that gives tremendous safety for any make/model tower cranes.

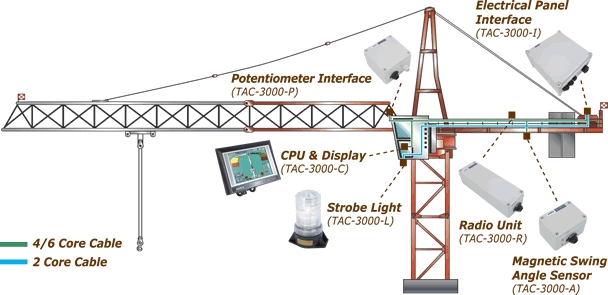

These anti-collision devices (ACD) come with a ground monitoring system through which one can monitor the functions of all tower cranes as well as upload data changes (like height increasing, protect some zones, etc) without stopping the cranes.

A single display shows the anti-collision functions, as well as the SLI, functions like load, radius, hook height, slewing angle and wind velocity to the operator without any confusion. This system integrates with the tower crane panels and will take care of the cut-off, alarm and display automatically without changing any OEM set-up.

This system is developed with a microprocessor, with battery backup so any power failure at the site does not affect the functioning. The communications are made through radio controls with non-licensed frequencies.

Working principle of anti-collision device

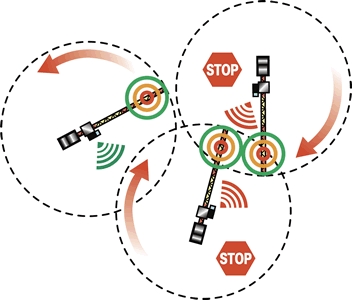

The Anti Crane Collision Switch is designed to avoid the collision of two adjacent cranes in the same bay running on the same rails. This system, when installed on the two adjacent cranes, will avoid the collision of two cranes. The system works on the principle of retro-reflective infrared waves. It consists of an emitter and sensor module and a special reflector.

The emitter emits the infrared waves in the direction of the reflector. The reflector reflects these infrared waves back to the sensor. The sensor senses the presence of these reflected infrared waves and activates an alarm signal and stops/reduces the speed of the crane. Thus if the two cranes are away from each other then the reflected waves will not reach the sensor and the crane operate normally.

The distance between the reflector and the sensor to detect the presence of infrared waves can be adjusted with the help of the potentiometer provided on the system. The maximum distances between the two crane to generate the alarm signal can be a maximum of 10 meters. The anti-collision system is specially designed for the Crane application and is suitable for continuous duty.

Anti collision sensor for cranes

Anti Collision and zone protection device can be easily installed with any make or model tower crane. The same device can also be used as a safe load indicator.

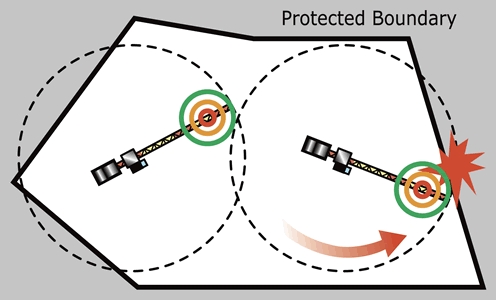

This system provides a clear visual position to the crane operator about all the installed cranes, structures, towers, and even trees as programmed around it by which the collision/accidents will be avoided.

The system includes a high-performance microprocessor, Software, wireless radio communication system and sensors to deliver accurate communication, data analysis, control, braking and data storage features. Touch Screen Monitor makes the installation and site setup simple.

Tower crane anti-collision system

It should come as no surprise to anyone in this industry that the second most common type of serious tower-crane incident reported in the last decade relates to contact with overhead power lines.

Unwanted contacts – between two cranes or between tower cranes and power lines.

While none of these reported incidents resulted in injury or death, several caused temporary power outages for thousands of nearby businesses and homes, many resulted in lost time or materials and damage to costly machinery, and all had the potential for serious injury, death, or catastrophic equipment failure.

As per the regulatory requirement, tower cranes and ancillary equipment involved in the incidents all had to be inspected, repaired if necessary and re-certified for use.

This statistic has helped guide the crane inspection team in developing its three-year Tower Crane Strategy, one element of which is a focus on raising awareness of the value of digital zoning and anti-collision devices.

Slew-limiting technologies have advanced steadily over the last 20 years. Sensors, interfaces and the software used to analyze the data have become very reliable, making the benefits for safe and efficient operation indisputable.

The collision of tower cranes may occur when two or more cranes over-sail with each other, any crane over-sail to the site’s boundary or to a prohibited zone. An example of a collision is the crane’s hoisting hook block & cable collides with the main jib.

This system, when installed on the two adjacent cranes, will avoid the collision of two cranes. The system works on the principle of retro-reflective infrared waves. It consists of an emitter and sensor module and a special reflector.

The most read

Crane Hand Signal Chart

What are the proper hand signals for cranes?

Tower Crane Controls

Due to the nonlinear nature of the rotating crane motion, controlling these oscillations is a complex task. Additionally, the lack of sensors on many cranes that are in use today requires extra effort to design effective control strategies.

Tower Crane Hand Signals

Every successful lifting operation is the result of planning and teamwork. The definition of teamwork is “a united effort by all to achieve the ultimate goal”.