Ancient Crane – medieval crane: The ancient cranes have been evolving from the load prop to perform various tasks. There are ancient documents where the use of machines similar to cranes by the Sumerians and Chaldeans is evidenced, transmitting this knowledge to the Egyptians.

Who invented the crane?

For centuries, archaeologists and historians have been baffled by how Stonehenge was built. The largest of the Sarsen stones transported to Stonehenge weighs 50 tons — which means that transportation by boat would have been impossible. Legend holds that ancient druids levitated the stones into place with their eldritch rituals.

The truth may be a bit less exciting, but just as interesting. The prevailing theory is that the stones were literally dragged using an intricate series of sledges, ropes, ramps, and levers.

The stones of the Pyramids of Giza were likely hoisted into place in a similar fashion. The “regular” slabs that tourists see on the outside surface of the pyramids are 3 tons each, but the biggest supporting slabs weigh up to 70 tons. Think that’s impressive? The Colossi of Memnon each weighed 700 tons each. By comparison, most common tower cranes today have a lifting capacity of only 12 to 20 tons, and most construction cranes go up to 300 tons.

History of cranes

For thousands of years, people have used innovative ways of lifting really heavy objects and bringing them where they’re needed. As demonstrated at Stonehenge, the Pyramids of Giza, and countless ancient sites around the world, the history of the crane is closely aligned with the history of the limits of man’s strength.

The birth of the crane is inextricably tied with the birth of the pulley — first devised by ancient Mesopotamians as early as 1500 BC for hoisting water. The first compound pulleys were created by Archimedes of Syracuse around 287 – 212 BC, which he used to lift an entire warship, along with its crew.

Ancient Egypt

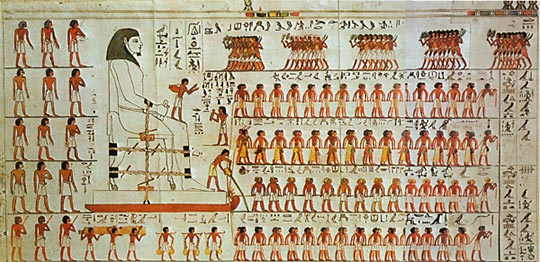

Most of the stones that make up the almost 140 Egyptian pyramids discovered have a weight of “only” 2 to 3 tons each, but all these structures (built between 2750 and 1500 BC) also have stone blocks that weigh 50 tons, a more times.

The temple of Amon-Ra in Karnak contains a labyrinth of 134 columns, of a height of 23 meters high and transversal beams that weigh 60 to 70 tons each.

The question is answered by a group of scientists from the University of Amsterdam and the Foundation for Fundamental Research on Matter (FOM), who discovered the techniques that allowed to build these monumental buildings at a time when there were no cranes.

In this painting the ingenious technique is observed. Water would have been the key element. According to the study, the ancient Egyptians moistened the sand where the wooden sleds on which the stone blocks were transported moved. The key would have been to spill the precise amount of water.

Ancient Greek inventions

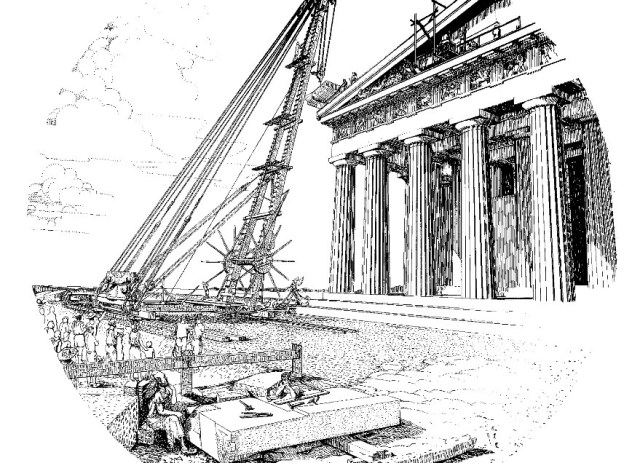

Cranes in ancient Greece: The first vestiges of the use of cranes appear in Ancient Greece around s. VI a.C. These are iron tongs marks on the stone blocks of the temples.

It is evidenced in these marks (distinctive cuts c. 515 BC) its purpose for the elevation since they are made in the center of gravity or in equidistant pairs of a point on the center of gravity of the blocks. The introduction of the winch and the pulley soon leads to an extensive replacement of ramps as the main means of vertical movement.

Greek buildings

For the next two hundred years, the Greek buildings contemplate handling of lighter weights, because the new lifting technique allowed the loading of many smaller stones to be more practical, than a few larger stones.

In contrast to the archaic period and its tendency to increasing block sizes, Greek temples of the classical age such as the Parthenon offered an invariable amount of stone blocks that could be used to load no less than 15-20 tons.

Also, the practice of erecting large monolithic columns was abandoned practically to then use several wheels that make up the column.

Although the exact circumstances of the change of ramp to crane technology remain unclear, it has been argued that Greece’s volatile social and political conditions made it more convenient to employ small teams for construction professionals than for instruments. Great for the work of inexperienced, making the crane preferable to the Greek polis than the ramp that required a lot of work, this had been the norm in the autocratic societies of Egypt and Assyria.

The first unambiguous literary evidence to support the existence of the system composed of pulleys appears in the mechanical exercises (Mech.18, 853a32-853b13) attributed to Aristotle (384-322), but perhaps drawn up at a slightly later date.

Around the same century, the block sizes in the Greek temples began to resemble their archaic predecessors again, indicating that the most sophisticated compound pulley in the later Greek works must have been found.

Ancient Rome

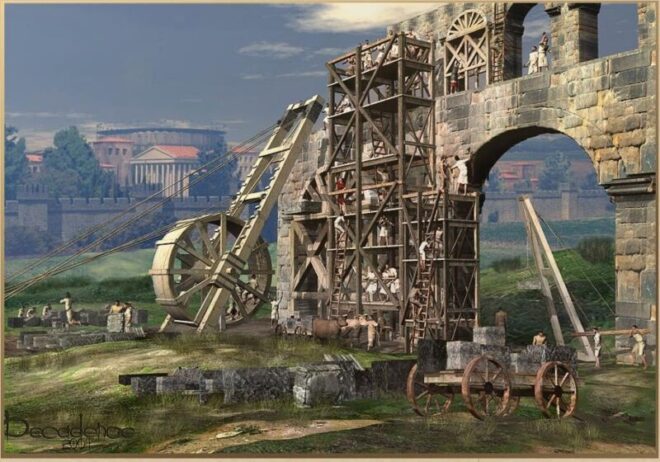

The height of the crane in ancient times came before the Roman Empire when the construction work was increased in buildings that reached enormous dimensions. The Romans adopted the Greek crane and developed it.

Trispastos

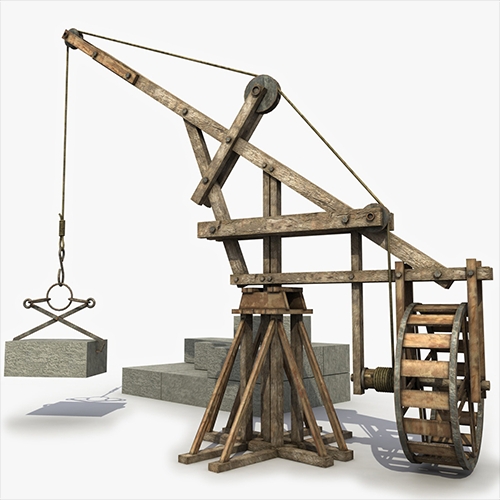

The simplest Roman crane, the Trispastos, consisted of a single beam, a winch, a rope, and a block containing three pulleys.

Having thus a mechanical advantage of 3: 1, it has been calculated that a single man who worked with the winch could lift 150 kilograms (3 pulleys × 50 kg = 150 kg), assuming that 50 kilograms represent the maximum effort a man You can exercise over a longer period.

Pulley system

Pentapastos: Heavier types of crane offered five pulleys (Pentaspastos) or, in the larger case, a system of three by five pulleys (Polyspastos) with two, three or four masts, depending on the maximum load.

Polyspastos, the cranes of Rome

The Polyspastos, when operated by four men on both sides of the winch, could lift up to 3000 kg (3 ropes × 5 pulleys × 4 men × 50 kg = 3000 kg). In case the winch was replaced by a coupling, the maximum load even doubled to 6000 kg with only half the equipment, since the coupling possesses a much larger mechanical advantage due to its larger diameter.

This meant that, with respect to the construction of the Egyptian pyramids, where about 50 men were needed to move a block of stone of 2.5 tons above the ramp (50 kg per person), the lifting capacity of the Polyspastos Roman proved to be 60 times higher (3000 kg per person).

Roman Architecture

However, Roman buildings offer numerous blocks of stone much heavier than those.

Led by the Polyspastos indicate that the total lifting capacity of the Romans went much further than that of any single crane.

In the temple of Jupiter in Baalbek, the blocks weigh up to 60 t each, and the cornices of the corner block even over 100 t, all raised to a height of 19 m above the ground.

In Rome, the capital block of the Trajana column weighs 53.3 tons and rises to a height of 34 meters.

It is assumed that the Roman engineers achieved the elevation of these extraordinary weights by two means:

- First, as suggested by Heron, a lift tower was installed, four masts were arranged in the form of a quadrilateral with parallel sides, not unlike a tower, but with the column in the middle of the structure.

- Second, a multiplicity of winches was placed on the ground around the tower, for, although it has a ratio of lower leverage than the couplings, the winches could be installed in higher numbers and performance by more men (and by animals).

This use of multiple winches was also described by Ammianus Marcellinus (17.4.15) with respect to the elevation of the Lateranense obelisk in the Maximus circus. The maximum lifting capacity of a single winch can be established by the number of iron holes in the monolith.

In the case of the Baalbek architrave blocks, which weigh between 55 and 60t, eight holes suggest a weight of 7.5 t for the iron of the packings, which is by the winch.

The elevation of such heavyweights in a concerted action required a large amount of coordination among the working groups that applied force to the winches.

Medieval crane

The coupling crane was reintroduced on a large scale after the technology had fallen into disuse in Western Europe after the fall of the Western Roman Empire.

The closest reference to a link reappears in the literature archived in France around 1225, followed by a painting illuminated in a manuscript probably also of French origin dated 1240.

Marine crane

In navigation, the closest applications of the port cranes are documented for Utrecht in 1244, Antwerp in 1263, Bruges in 1288 and Hamburg in 1291, while in England the link is not recorded before 1331.

Generally, vertical transport was safer and cheaper made by cranes than by other methods common to the time.

The areas of ports, mines, and, particularly, the building where the crane of couplings played an important role in the construction of the tall Gothic cathedrals.

However, the archived and illustrated sources of the time suggest that the machines were reintroduced as couplings or trolleys so that they did not totally substitute the most labor-intensive methods such as ladders, troughs, and stretchers.

Something that is important to mention is that the old and new machinery continued to coexist in the sites of the medieval works and in the ports.

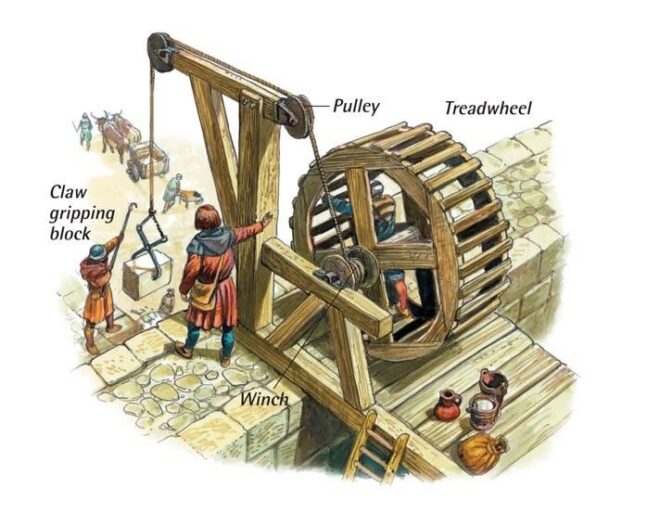

Crane Wheel

A wheel crane (Latin: Magna rota) is a wooden, human-powered crane. It was used mainly during the time of the Romans and the Middle Ages in the construction of castles and cathedrals.

The often heavy loads were elevated while an individual walked inside a cage-like wooden wheel. The rope connected to a pulley is wound on a spindle by the rotation of the wheel, thus allowing the device to lower or lower the platform with the load to be moved.

Old wooden crane

The Crane of Gdansk (Poland), a symbol of the city, was the largest crane in Europe in medieval times. The first mention of a wooden crane in this place is 1367.

In 1442 it was burned and from 1442 to 1444 the crane that is currently known was built in the Puerta del Espíritu Santo.

The door was one of the entrances to the citadel, and its brick towers were used to load and unload the merchandise of the ships.

In the middle of the two towers was placed the elevator with its wooden mechanism. The first crane lifted the goods up to 11 meters.

In the seventeenth century, the upper crane was built that lifted the goods up to 27 meters. In the nineteenth century, it ceased to be the freight crane of the port and was used to fix the masts of the ships.

Later it would be used to extract the stern of the motorboats and repair the rudders. In 1858 the last master who controlled the crane died and a shoe factory, a hairdressing salon, and other local companies were installed there.

During World War II, the wooden area burned as well as 60% of the towers.

From 1955 to 1962 it was rebuilt following the original plans and became dependent on the Central Maritime Museum along with the ship Soldek, the first ship built in Poland in the Gdansk shipyard in 1948.

Medieval crane Gdansk

Medieval crane of Poland: It has been used to celebrate the Red Bull Cliff Diving competition. The mechanism that allowed to unload merchandise, especially wheat and beer, works through the motive power of the feet of the workers.

It consists of two drums of two meters in diameter where the operators were introduced. These workers walked on some boards or steps that made the drum rotate.

The rotating drum raised or lowered the pulley. Thanks to this mechanism, four workers could lift two tons. At present, you can visit the inside of the “crane”, as they call it in Gdansk.

On this visit, you can see the interior of the mechanism as well as the reconstruction of a house of accounts of a merchant, the tax office of the port taxes and the house of a bourgeois. It also explains the life of stevedores, transporters, merchants, employers, candle makers, rope makers, etc …

Treadwheel crane

Styled like colossal human hamster wheels, these cranes allowed huge loads to be hoisted with ease.

The treadwheel crane was a wooden, human-powered lifting and lowering device invented in Ancient Rome. It was used in construction and industry for lifting all manner of materials and produce.

Its creation was a revelation at the time, granting a single person the ability to lift roughly 3,000 kilograms (6,600 pounds) of weight, rather than a completely manual 50 kilograms (110 pounds). As such, while it could take 50 workers to haul a 2.5-ton block of stone during the construction of Egypt’s pyramids, by using a treadwheel crane, the equivalent load could be lifted in Roman construction projects by just three.

Key to this was the huge mechanical advantage granted by the large-diameter treadwheel; it acted as a force amplifier, with the low force input of the treadwheel workers increased dramatically at the output end.

A typical system placed two peddlers side by side in a large, tracked wooden wheel, itself turning around a central shaft. As the wheel was set in motion by the pacing of the workers, it would rotate the central shaft, which in turn would draw in or let out a connected pulley.

The pulley extended out along the crane’s lifting bar and then down to the floor, where objects could be either loaded or unloaded.

Despite its fairly crude design, the treadwheel crane remained in widespread use right up to the end of the 18th century.

Hydraulic crane

Ancient irrigation systems, like the aqueducts developed by the Romans, relied on simple hydraulic technology, like siphoning and hushing in hydraulic mining.

But it was not until the 15th century that Blaise Pascal studied fluid hydrodynamics and hydrostatics, ushering in a new understanding of hydraulic principles like fluid density, pressure, and incompressibility.

A crane is a mechanical lifting device equipped with a winder, wire ropes and sheaves that can be used both to lift and lower materials and to move them horizontally. It uses one or more simple machines to create mechanical advantage and thus move loads beyond the normal capability of a human.

The crane for lifting heavy loads was invented by the Ancient Greeks in the late 6th century BC. The archaeological record shows that no later than c. 515 BC distinctive cuttings for both lifting tongs and lewis irons begin to appear on stone blocks of Greek temples.

Liebherr Mobile Crane

Category: Mobile

Lifting Capacity: 1,200 metric tons

-The Liebherr LTM 11200-9.1, built by the German company Liebherr Group, is the most powerful mobile crane ever built.

-It also has the longest telescopic boom in the world, which extends fully to 100 meters.

-It’s set on a double cab truck and can lift 1200 metric tons – that’s nearly 700 automobiles.

-That’s real pound-for-pound power for its category, but ultimately not the strongest crane in the world when compared to stationary cranes.

The most read

What is a crane?

Who invented the crane? What are cranes used for? How does a crane work?

Crane Manufacturers

Crane Manufacturers: Cranes brands, the recognized brands in the world of Liebherr, Caterpillar, Hiab, Palfinger, Terex, Komatsu construction cranes

Tower Crane Equipment

A tower crane is a construction machine designed to load and unload different materials. This load is distributed through the use of a hook that remains suspended thanks to the use of a cable.