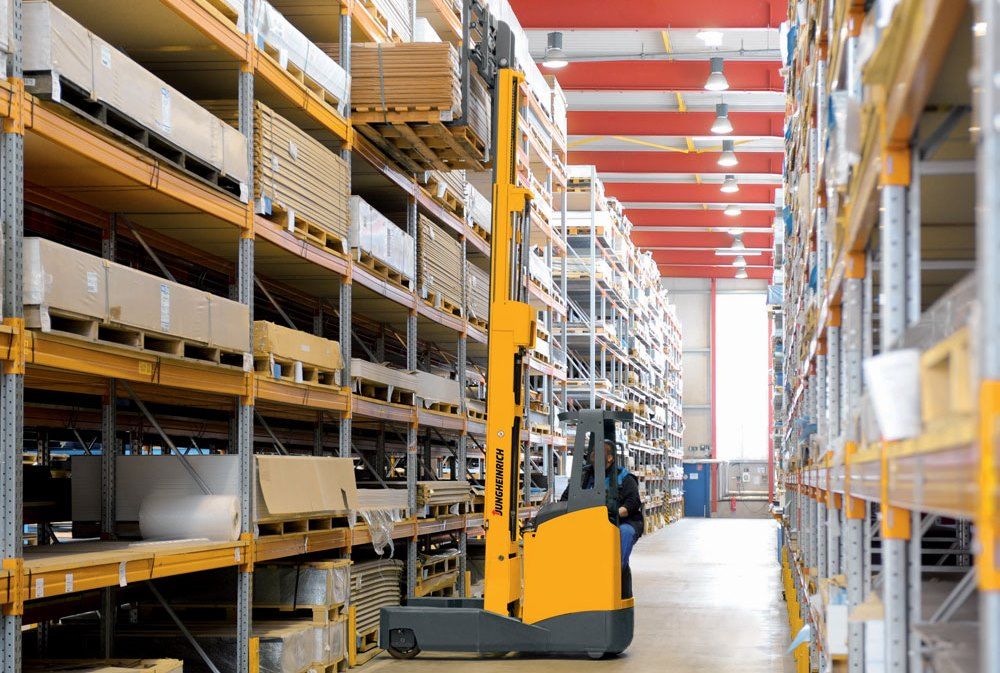

A reach truck is designed to reach extreme heights. They are best suited for narrow aisles lined with tall shelving and are traditionally found in indoor work environments.

They are very maneuverable and can be extended beyond their stabilizing legs to obtain products that are difficult to access. Additionally, most reach trucks have a tilt mechanism that allows better visibility for operators.

What is the difference between forklift and reach truck?

A reach truck is a smaller vehicle than a forklift, allowing it to remain much more agile.

It has a slimmer chassis and holds loads closer to its wheelbase, allowing it to perform well in warehouses with narrow aisles and tighter spaces.

Instead of a counterweight, a reach truck has two outer stabilizing legs that distribute the weight of the load.

What is the difference between forklift and reach truck?

Understanding the difference between a forklift and a reach truck is important, whether you’re planning to lift lightly or begin your operator training.

Not many people know this, but forklifts are a general term for a variety of lifting and loading vehicles that are made for specific jobs. Each type of forklift has a specific method of operation.

Two of the main types of forklifts include: counterbalanced forklifts and reach trucks

Our goal here is to help you better understand these two forklifts so that you can choose the right one for the job at hand.

What is reach truck?

Reach trucks are forklifts used in narrow aisle applications such as warehouses.

They are designed to have two outer legs that help distribute the load and a single set of wheels at the rear. The wheels are located under the operator, helping to create a tighter turning radius.

This allows operators to navigate smaller spaces and still be able to reach higher racks.

Making your aisles taller and narrower is a good way to create more space when your warehouse gets tight, but it can also make navigation and material handling difficult.

Reach trucks can be used in any warehouse, allowing operators to easily enter and exit narrow aisles and reach significant heights, all while maintaining lifting capacity. Reach trucks enable unmatched confidence in challenging warehouse environments.

Although some models allow a forward stance, the operator generally sits on the side, allowing for maximum comfort and maneuverability.

Reach trucks include several features to improve operator visibility.

The cab can be tilted to help the driver have a better view or have an open protective roof.

Many reach trucks come with a camera, allowing the operator to see what is happening overhead on a video screen.

Reach truck capacity

Reach trucks can generally handle less capacity than a traditional counterbalanced forklift.

Besides working in tight spaces, the other advantage of a reach truck is its maximum height.

With maximum lift heights on some models extending above 40 feet, reach trucks allow your business to scale your storage vertically.

In addition, since all forklifts have a multi-capacity electric battery, they are quiet and emit no emissions, making them even more suitable for indoor work environments.

Stability triangle forklift

One of the main differences between a counterbalance forklift and a reach truck is the method used to stabilize their loads.

As the name suggests counterbalance forklifts are designed with a larger counterweight in the rear of the unit.

This weight directly offsets the weight of the load being carried out front on the tynes thus greatly reducing the likelihood that the unit will tip over when operating.

Reach trucks do not have an external counterbalance weight instead they rely on two features to stabilize their loads, stabilizing legs extend out and to the side of the tynes combined with the weight of the unit’s battery to keep the unit stable reducing the risk of it tipping over.

Counterbalance forklifts and reach trucks have been specifically designed to carry out different tasks.

The ability to design counterbalance forklifts with larger counterweights in the rear allows them to lift and move heavier weights than reach forklifts.

How to operate reach truck?

Stand-up forklifts (also known as stand-on and electric riders) are designed for applications where the operator must get on and off the lift truck frequently. They are more maneuverable and need less space to operate than sit-down forklifts.

Reach truck Controls diagram

Reach trucks are capable of maneuvering in small spaces and lifting objects into high-up, hard-to-reach places.

Forklift and Reach trucks

In a forklift, the main characteristic is its price, maintenance, and spare parts. The capacity of these machines to support weight simplifies the movement, transfer, and order of the merchandise.