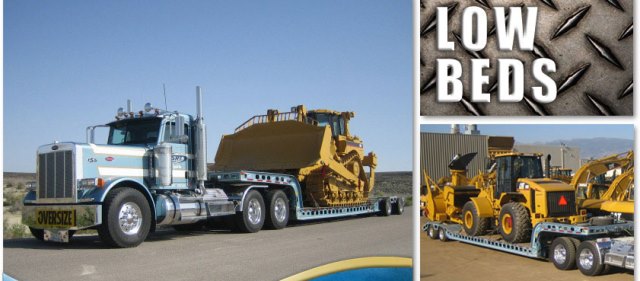

Construction Equipment Hauling: What kind of trailer should I use? Safety is the most important element in transporting construction equipment. To make sure the equipment and the driver are safe, you want to be sure you use the best trailer for the job. The capacity of the trailer is the first thing to consider, followed by state regulations and laws. Construction equipment hauling companies use the following types of trailers:

- Flatbed Trailers

- Removable Gooseneck Trailers

- Double Drop Trailers

- Specialized trailers

- Lowboy Trailers

- Step Deck Trailers

- Hotshot Trailers

- Extendable Trailers

Best trailer for hauling heavy equipment

Types of trailers for hauling heavy equipment

The most common hauling equipment used for any construction work are the 5- and 20-ton dump trucks, both of which are organic to most engineer units. Equipment trailers are used to transport heavy construction equipment not designed for cross-country travel. They are also used to haul long, oversize items and packaged items.

Dump Trucks

The 5-ton family of medium tactical vehicles and the 20-ton dump trucks can be used for a variety of purposes. This manual, however, discusses dump trucks used primarily for hauling, dumping, and spreading earth, rock, or processed aggregates.

Capacity

The capacity of hauling equipment is expressed in one of three ways:

Gravimetrically by the weight of the load it will carry (in tons), by its struck rear-dump body volume (in cubic yards), or by its heaped rear-dump body capacity (in cubic yards). The hauling capacity of Army dump trucks is normally expressed gravimetrically: 5-ton and 20-ton.

Conversely, the capacity of loading equipment is normally expressed in cubic yards. The unit weight of the various materials to be transported may vary from as little as 1,700 pounds per LCY for dry clay, to 3,500 pounds per LCY for trap rock. Always make sure that the volumetric load does not exceed the gravimetric capacity of the truck.

Loading

For maximum efficiency, fill trucks as close to their rated hauling capacity as practical. Adjust the load size if haul roads are in poor condition or if the trucks must traverse steep grades. Overloading will cause higher fuel consumption, reduced tire life, and increased mechanical failures.

Use spotting markers when trucks are hauling from a hopper, a grizzly ramp, or a stockpile. Spotting markers are also beneficial when excavators (such as a dragline, a clamshell, a loader, a backhoe, or a hoe) are used to load hauling equipment. They facilitate prompt and accurate vehicle spotting which improves loading efficiency.

Spot trucks as close to the bank as possible when loading with an excavator. Ensure that the trucks are within the working radius of the dragline, the clamshell, or the hoe bucket. When using a loader, position the truck and loader so that the two machines form a V. This arrangement will reduce the loader cycle time.

Maintaining Proper Speed

10-6. Haul at the highest safe speed and in the proper gear, without speeding. Speeding is unsafe and hard on equipment. When several trucks are hauling, it is essential to maintain the proper speed to prevent hauling delays or bottlenecks at the loading and dumping sites. Use separate haul roads to and from the dumpsite, if possible. Keep haul roads well maintained, with a minimum grade. Use one-way traffic patterns to increase efficiency.

Dumping (Unloading)

Always use spotters to control dumping operations. When dumping material that requires spreading, move the truck forward slowly while dumping the load. This makes spreading easier. Establish alternative dumping locations to maintain truck spacing when poor footing or difficult spotting slows the dumping operation.

Preventive Maintenance

Keep truck bodies clean and in good condition. Accumulations of rust, dirt, dried concrete, or bituminous materials hamper production. Consider the time spent cleaning and oiling dump bodies, particularly for asphalt or concrete hauling, when computing transportation requirements.

- Clean truck bodies thoroughly at the end of the day. When used to haul wet concrete mix, spray the dump beds with water before loading and clean them thoroughly as soon as practical after dumping.

- Coat the walls and sides of truck bodies with diesel fuel or oil to prevent bituminous materials (plant-mix asphalt) from sticking

Heavy equipment hauling

Heavy Equipment Trailer Rental

Use equipment trailers to transport heavy construction equipment such as cranes, dozers, or any equipment not designed for long-distance movement by their own power. Also use the trailers to haul long items such as pipes or lumber, or packaged items such as landing mats or bagged cement.

Loading

For maximum efficiency, load trailers are as close to their rated load capacity as possible. When loading, always place a spotter on the trailer to direct the equipment operator and keep the machine centered on the ramps and trailer.

With rear-loading trailers, use low slopes or constructed dirt ramps when possible. Some trailers have loading ramps for loading from level ground.

When using loading ramps to load a bulldozer, run the machine slowly up the ramps (with the blade raised) and when balanced, slow or stop, then lower the blade and let the front of the blades tracks sit smoothly on the trailer bed.

Then move the excavator slowly towards the trailer. Some low bed trailers are designed for front-loading.

In areas that restrict rear loading, load the trailer from the side. Be careful not to damage the trailer bed.

Note: Refer to the unit’s SOP or to the appropriate technical manual for proper techniques for loading and securing equipment.

Positioning and Securing

After positioning the equipment on the trailer bed, block and chock it and chain it to the trailer. Properly distribute the weight of large equipment on the trailer. Trailers have their load-weight centering position marked.

Unloading

Unload heavy equipment slowly to prevent damage to the trailer or the equipment. Always use ramps to load and unload.

Heavy equipment hauling companies

Preparing for heavy haul transport:

To be ready at pick up, speak to your transporter beforehand and make sure they have all the necessary permits for transport. Also, ask them how you can help prepare your equipment for transport.

They will give you tips based on their experience and your specified shipment. For example, your transporter may advise you to bubble wrap fragile levers within the cab of a tractor or secure the doors of a crane shut with zip-ties. Talk with your provider ahead of time to work out any necessary permits.

Construction equipment transport

There are a few steps you can take to prepare your equipment for shipping:

Consult the manufacturer’s manual, it is the first step to preparing your machinery. You can have the manual yourself, or you can look it up on the manufacturer’s website. This manual may recommend that you take certain actions, such as disconnecting batteries, draining fluids from the engine, or securing loose parts.

Obtain the necessary permits: There are specific guidelines for securing and transporting heavy equipment.

Oversized and overweight cargo will require special permits to be transported by road.

Remember that large equipment loaded on a trailer may be too tall to drive under power lines and bridges, or to travel on certain roadways.

You must work with the carrier prior to the pickup date to obtain these permits, avoiding delays or legal complications.

Cover vulnerable parts – Remember that your equipment will likely be transported outdoors and therefore exposed to the elements.

Cover any part that is vulnerable to rain and wind. In the winter months, be prepared for damage to tanks and lines due to cold and freezing temperatures.

You may also need to protect your computer from heat. Consulting your owner’s manual should provide guidance on protection.

Be prepared to pick up and drop off: You will need an open area at the pick-up and drop-off points to load and unload your equipment. Necessary equipment for loading and unloading, such as loading docks, ramps, or cranes, can also be added.

Construction Equipment Hauling

The cost to transport heavy equipment varies greatly based on the equipment being transported. The cost to ship heavy equipment longer distances, over 500 miles, averages $1.75 per mile, while shorter distance shipments average $5.00 per mile

There are several different types of hauling equipment that can be used for building and construction. Some of the most typical types include cranes, bulldozers, forklifts, dump trucks, and excavators, as well as many others.

Heavy haulers pay an average of $80,000 or more in 2018. They earn their pay in extra responsibility and work. You usually can’t go into hauling heavy equipment right out of trucking school.

In the U.S. a superload is a truck tractor with an attached trailer that has an over-dimensional or overweight object (the load) on it that exceeds the ordinary permit limits commonly associated with oversize or overweight loads.

The most read

Heavy Equipment Transport

Unlike shipping standard freight, heavy equipment transport requires special handling, oversize load permits, and special freight carriers.

Heavy Equipment Movers

If you’re looking at moving some heavy equipment, it’s important to work with a skilled professional who’s capable of taking that job on, as it requires a lot of knowledge to get the task done safely.

Heavy Equipment Hauling

Consider carefully all your options for hauling your construction equipment.

Heavy Equipment Rental

Rental is a prominent and growing model in the construction business. The development of the rental industry in new markets requires a certain level of trust in a country and in society.