Tower Crane Rental: The economic benefits obtained at the end of a certain project are directly related to the planning and programming of costs that are made from the beginning include the rental of cranes and construction machinery.

These construction teams will ultimately determine whether there will be financial success or failure on a construction project.

Tower crane rental cost

The global tower crane rental market has witnessed an upward surge in the past few years. This is attributed to the lesser costs associated with renting such equipment when compared with purchasing new equipment.

The overall purchasing cost of tower cranes is very high. This cost increases further owing to the maintenance cost of the equipment. Such costs cannot be termed as affordable for small and medium enterprises.

Tower crane rental companies

These enterprises can rent tower cranes easily according to their budget and requirement, which reduces the overall cost of the construction project. Moreover, this also helps them save the long-term maintenance costs of the equipment. This is the reason, why most enterprises are inclined towards renting the equipment instead of purchasing them.

Moreover, governments across the globe are focusing on developing their infrastructure and expanding the real estate sector. Additionally, the increasing investments in the construction industries along with the growing remodeling and renovation projects, across the globe, resulting in the growth in the construction of high-rise building projects.

This has led to an increased demand for tower crane rental on a global scale.

Construction crane rental

One of the main points to consider in planning is the rental of cranes and the choice of machinery to use.

Specifically, when we talk about a project at a high altitude, where an important point is to adequately solve the lifting needs, we must think carefully about the machine that will best respond to the requirements.

The machines that are considered in this case are the tower cranes, of which there is a wide variety in the market, the reason why the different existing alternatives must be carefully studied.

Tower crane cost per day

How much does the rent cost per day?

If the final decision of the project management team is to use a tower crane, it is also important to bear in mind that the rental of tower cranes has the following advantages:

- Tower cranes have a distinct advantage with respect to platform lifts or crane trucks because the boom or jib rises over the construction site.

- The boom of the crane can put its weight in any part of its operating radius, without interfering with the structure on which it is balanced.

- In addition, the operator can be on the crane or remotely controlled using instrumentation located in the structure of the building, while enjoying an excellent view of the cargo and its surroundings at all times.

It is important to bear in mind that there are many types of tower cranes, which is why it is essential that the people involved in the management of the project handle accurate and accurate information on the different possibilities.

Tower crane specification

The best choice should undoubtedly be among those that result in a lower cost but that covers the maximum usable area since the price of renting tower cranes is related to its size.

It is also important to evaluate the number of tower cranes, which will be needed.

To know if more than one tower crane is necessary, the average lifting cycle must be determined, but also if the work area is quite extensive it may be necessary to have one or more tower cranes in the work.

Although the latter can also be solved by adding a rail to the crane that allows its movement, thus covering a larger area.

The programming of the work must ensure that while the crane is used in a certain area, other jobs are not interrupted.

In addition, one should think about the reprogramming of those activities, where the tower crane must be used during prolonged periods during the day, by night shifts.

How to calculate tower crane rental rates?

Tower crane installation

The factors that will ultimately determine the choice, are the lifting capacity, the reach of arrival, the height and location of the tower crane.

The tower crane can adopt different locations, among which is:

Inside a building

If the crane is to be located inside the building, temporary holes must be provided through the slab system, unless there is an elevator box located in the center, a scale box, or other opening large enough to accommodate the tower (with space). to allow oscillation.

Tower crane location

The structural engineer of the project must evaluate and approve the location of these holes.

Preferably, the holes should be made should only be made through slabs, not beams or pillars, and will probably require additional reinforcement or other structural modifications.

Unless adjacent structures make it difficult for the crane to swing freely, it should initially be erected high enough to clear the first floors, then climb the building as it rises.

The climbing is carried out by lengthening the tower or lifting the tower from its foundation and holding it on the completed floors.

The last method requires additional reinforcement of the structural system by several floors (this must be consulted with the structural engineer) but allows the floors that the tower crane has passed to be finished.

The size of the foundation must be minimal, depending on how high the crane is erected in its initial position. As the crane is lifted it can be attached to the building, to prevent its overturning.

Tower crane foundation

Care must be taken not to interfere with the foundations of the building. If this happens, the foundation of the crane should be designed by a structural civil engineer, preferably one with experience in tower cranes.

If the foundation of the crane requires piles, the design will be completed well in advance so that these piles can be installed while the person carrying out the work is still on site.

A crane attached to the building requires, while lifting, foundation design for its weight and its highest final position as well as for its initial period when it is positioned free and subject to overturning.

In all cases, the foundation will be concreted with welded anchors to the first section of the trunk of the tower to ensure that it is completely vertical.

In addition, protection should be provided to the base of the crane tower to prevent any chance of something hitting them.

Outside the building

If the tower crane is to be located outside the building, it must be close enough, so that its structure is tied to the construction every two or three floors.

Technical specifications: The crane can be erected high enough to clear the first floors and then climb the building as it rises.

Mooring with the building prevents the use of self-deflecting wall moldings or flying deck moldings in the mooring positions, as well as delaying the final closure of the area immediately in front of the crane tower until the crane is removed.

Contractors and engineers should exercise care in selecting the location to minimize the amount of work very close that could be delayed.

The position of the crane outside the building should avoid disturbing the existence of underground elements unless the plans say that they must be relocated.

The blueprints of the project must be studied for the projected worksite, such as public utility lines, and swimming pools to avoid a situation in which the foundation must be removed after the dismantling of the crane.

Foundation Crane Tower: The foundation of the tower crane in these cases is generally large (2-3 m2 and 1.7 m deep), requiring a design for its lifting and additional installation of larger anchors in the concrete.

Completely outside the building

This requires a crane whose boom length is greater than other options. Foundations must be designed for maximum final solicitation even when initially erected at a minimum height, the foundation must be equipped with escalation links.

The positioning should minimize or eliminate the possibility of blocking the wheel slab moldings.

Cranes on rails

A tower crane on rails allows covering a larger area. The crane must rest on a special car, wide enough and with a counterweight to prevent a rollover, and be equipped with bogies and motors to move.

Foundation: The placement of the rails must be based on concrete or compact gravel designed by a structural engineer and that reflects the ability to support the ground.

The rails can be curved according to the recommendation of the crane manufacturer.

A crane mounted in this way can use electricity from a variety of sources via cable, or it can supply its own power with a generator mounted on the rail.

Recommendations: The first installation of the crane at its maximum height without the use of winds, can save time in the long run, although initially, it positions its operator away from work.

Since each climbing takes several hours, this work can prevent a sequence of the floor by floor with its realization.

Night construction work

Performing this operation during the night shift, where local regulations and working conditions permit, can take the crane to the necessary height without interfering with daily activities.

Where two or more tower cranes are used, they can be positioned so that their booms can swing over a common area.

These arrangements require great care so that the cranes below can swing 360 degrees without hitting each other.

The length of the load cable for the crane must be adapted to reach from its maximum height to the lowest point, in which it will receive loads, in addition to the number of wraps needed in the drum.

As part of the decision, when using a tower crane, a plan is needed for the lifting of the crane, for its dismantling, and for its removal.

The access of lifting equipment must be evaluated and chosen carefully.

It is often necessary to reinforce the pavement of the street, secure the excavations to support the lifting equipment, and also obtain special permits.

Tower crane brand

The tower cranes with which we work are mainly:

- Linden- Comansa

- JASO

- Liebherr

- Potain

- BPR Cadillon

- Richier

They usually operate by entering into a lease agreement, which stipulates the general conditions of the process between the parties.

These conditions are fundamentally oriented to define the way in which collection will be made for the use of equipment, almost always establishing a basic lease.

That corresponds to a monthly charge considering the use of the equipment for a certain number of hours (usually 200 monthly hours).

It also defines what corresponds to the hourly rates: for the equipment, the rate results from dividing the basic monthly rent by the agreed number of hours.

Now for the operator, this rate corresponds to the value resulting from dividing the operator’s basic monthly rate by the agreed number of hours, in both cases the hourly rate is wound by hours.

If the equipment is used for a longer time than the agreed hours, an additional charge is made, corresponding to the value resulting from multiplying the number of hours in excess by the hourly rate.

Similarly, if the operator is used for a longer time than agreed, an additional charge will be made, which will be determined by multiplying the number of hours in excess by the operator’s hourly rate, recharging it by 50%.

Other conditions refer to charges that are made for operations such as assembly, disassembly, placement of bracings, in extraordinary working hours, here a surcharge is generally made of 50 % on the normal rate.

Tower crane hire prices

Customer responsibility: It also defines what will be the client’s responsibility and cost, such as:

- Fabrication of bracing struts

- Use of auxiliary support equipment for loading

- Download, assembly, disassembly or other operation.

- Protection of electric cables.

- Supply and installation of rails for mobile cranes.

- Have the permits and insurance of work required during the lease period and according to the requirements of the Works Directorate of the corresponding municipality.

- Construction of the support foundations required for the assembly of the equipment.

It also establishes how the maintenance will be carried out by the company that is providing the leasing service, duly agreeing to the dates and times of the maintenance.

Construction Industry

Today tower cranes are a powerful tool in the construction industry, in medium and high-rise construction, as well as in any other activity where they can be used.

Thanks to them it is possible to transport all types of loads within a work, in a fast, safe and simple way.

There are several types of tower cranes. Each variety was developed to respond efficiently to the different working conditions that are presented in the works.

The classification that is made is based mainly on differences in terms of the form of support, a form of assembly, and the tower crane boom length.

Accident prevention

The high cost, risks of serious accidents, and high impact on the productivity of a work where a tower crane is used; they force to strictly comply with the safety measures that are recommended in the stages of the transfer of the parts, assembly, operation, and disassembly of the tower crane.

Special care must be taken in carrying out the maintenance of the crane; an inspection program and a very rigid preventive maintenance plan must be implemented.

This will allow the tower crane to remain in perfect conditions of operation and safety.

Crane operator

The personnel in contact with a tower crane must have basic knowledge about it, in terms of operation, operation and safety measures to be adopted in each case.

People who work directly with the tower crane, both in the installation, maintenance, and operation, must be specially qualified people.

The operator of a tower crane must meet certain physical and psychological requirements that enable it to perform a correct job.

It is also important to mention the work of the signalman, who often also guides the operator in certain conditions of poor vision.

It must carry out the strobing or slinging operations of the loads to be hoisted, which is why it must have adequate preparation for the importance of the handling of the loads.

Tower crane rental rates

Evolution is a process to which the tower cranes are not oblivious. Every day we work on finding the best solution for each new need, either by creating new models or improving existing ones.

Using new materials or incorporating new components, applying for all this, the highest technology available in the market.

The process of selecting the type of tower crane, which will be used in a specific project, must be carried out in a responsible manner by a team that manages adequate information on the different possibilities.

The final decision must correspond to that tower crane, which best suits the needs in terms of lifting capacity, reach, height, and location of the work, and that above all represents a good investment.

How much does it cost to rent a tower crane?

The typical fee for installation and disassembly runs around $60,000. This price includes shipping the crane to the site, renting the mobile crane used to assemble the tower crane, the cost of the crew that handles the assembly, etc.

In 2018, the Bureau of Labor Statistics indicated that the average, annual crane operator salary was $55,750. Experienced crane operators that are working on large-scale projects may make as much as $84,250.

Most operators learn primarily through on-the-job training rather than formal education. Other important skills for heavy machinery operators include alertness, hand-eye coordination, attention to detail, and the ability to follow instructions closely.

To apply for a New York Crane Operators certification, applicants must have at least three years of experience within the five years prior to submitting the application under the supervision of a licensed Crane Operator.

Candidates for tower crane operator certification must pass both a written and a practical exam; after which they will be certified for a five-year period. All exams must be completed within 12 months. The Tower Crane written exam consists of a single examination in Tower Crane operation.

The average pay for a Crane Operator is $24.50 per hour.

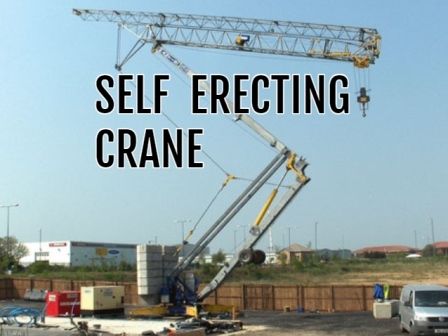

Self Erecting Crane Rental

Self-erecting tower cranes have long been commonplace in Europe. Their versatility and reliability have made them a mainstay on the European Jobsite.

How much does a Tower Crane cost to Rent?

Is tower crane rental profitable?

The most read

How much do Tower Cranes Cost?

The cost of a tower crane can vary widely depending on several factors, including the type, size, and brand of the crane.