Risk Assessment for Lifting by Crane – Lifting operations risk assessment:

While the information in hazard identification, risk assessment, and risk control measures are not exhaustive, the manual provides practical guidance for the safe operation of the crane, provided that the crane is used in accordance with the designers/manufacturer’s recommendation for which the crane is designed and manufactured.

Lifting operations risk assessment

Risk Assessment for Lifting by Crane:

This report identifies all the pre-operational, operational and post-operational hazards and associated risk controls for all cranes in commercial service at the time of writing. In addition, hazards associated with attachments are also included together with the recommended risk controls.

This section lists the potential hazards and risks control precautions that should be observed when operating or maintaining cranes.

The points raised here must be fully understood and observed to work safely. Read and understand the operation and maintenance manuals.

Further precautions may be necessary due to the attachments in use or the site conditions. The user should continually re-evaluate the site conditions as the working environment has a major influence on the risk associated with the use of Pick & Carry cranes.

Risk Assessment for Lifting by Crane

- GENERAL HAZARDS

- RISK CONTROLS & GENERAL PRECAUTIONS

- Unintended movement of the crane due to clothing getting caught or tangled in control levers and mechanical parts.

- When driving or operating the machine, do not wear clothing with dangling parts, which might catch on control levers or mechanical parts. Wear appropriate personal protective equipment as necessary.

- Unintended movement of the crane from operating wrong controls or errors in judgment.

- Do not operate the crane when you are excessively fatigued or unwell.

- Read the Operators Manual & Risk Assessment (“this manual”) thoroughly, familiarizing yourself with all controls before you start operating the crane.

- Follow instructions and warnings in this manual and on plates and stickers mounted on the machine.

- If there is something you do not understand, have it explained to you. If the manual is lost, or a warning label is illegible, replace it.

- Fire and emergency response.

- Carry a fire extinguisher and first aid kit in the crane.

- Learn how to use the fire extinguisher before an actual emergency situation arises.

- Fire from handling chemicals.

- Do not smoke or use fire near fuel, oil, antifreeze, batteries or other chemicals, which could ignite.

- Extinguish all fires and potential sources of ignition when handling these flammable materials.

- Before refueling the crane, switch off the engine and check that there are no fires or potential sources of ignition nearby.

- After refueling securely fasten all fuel and oil caps and wipe off any spillage.

- Refuel and change the oil in a well-ventilated work area.

Risk assessment crane lifting operation

Risk Assessment for Lifting by Crane:

- GENERAL HAZARDS WORKING PROCEDURES

- RISK CONTROLS & GENERAL PRECAUTIONS

- Unfamiliarity with site conditions or scope of work

- Plan for the crane operations as early as possible. Planning should involve inspection of the site, consultation with all persons involved in the work such as the principal contractor, crane hirer, energy suppliers, employer, dogman, spotter, site foreman and crane operator.

- Not observing instructions on warning labels could cause operation beyond the limitation of the crane.

- Observe all instructions on the warning labels. Ensure that all warning labels are clean and legible. If the warning labels are damaged or illegible replace them.

- Collision with people or objects in the work area.

- Before starting work, check the work area for the presence of roads, overhead powerlines, nearby structures, other cranes, aerial hazards and other obstructions.

- Isolate the work area by using witches’ hats, temporary barriers or fencing.

- People, vehicles, etc. should be prohibited from entering the isolated area.

- Consult the principal contractor, site supervisor, the other crane operators and everyone involved with the work and prepare a safety plan for the job.

- Always be aware of your surroundings and the hazards while you work.

Mobile crane risk assessment example

- Collision with other cranes and structures.

- When operating a crane, consider hazards such as overhead powerlines, nearby structures, other cranes, high obstructions and other mobile equipment within the crane working area.

- During articulating or reversing

- When you need to articulate or reverse in areas of restricted visibility, place a guide or use a spotter and follow their instructions.

- From dirty windows and mirrors

- Keep the cab windows, mirrors, wipers and working lamps clean.

- From poor lighting.

- When working in areas with poor lighting switch on the lights. If required use additional illumination (mobile lighting can be hired from equipment hire places).

- From adverse weather conditions.

- When visibility is bad due to fog, snow, rain, or other adverse weather conditions stop work and do not start again until conditions have improved.

Safe work procedure for lifting operation using mobile crane

- Collision with people or other vehicles when working on public roads

- When working on public roads, position a guide and erect fences, witches hats, etc. Observe all the traffic rules and safety regulations and laws of the Country or State where the crane is being used.

- Collision with objects and people working in the work area.

- Discuss your requirements with the site supervisor. If you consider that the people and equipment in the area have to be removed before you operate the crane, discuss it with the site supervisor so the necessary arrangements can be made.

- Electrocution from live overhead conductors. If you are working close to power cables you can also receive a shock even if the crane does not physically contact the cables.

- Take the following precautions when working near power cables.

- Contact the managing company in advance and arrange for electricity to be switched off (if possible), or arrange for cables to be fitted with protective devices.

- Keep a safe distance between the machine and the power cables. Consult the electricity authorities on the location and voltage of cables on the site and the minimum isolation distance.

- Use a spotter and follow their instructions.

Mobile crane lifting hazards in the workplace

- Inadvertent operation of the cranes due to poor housekeeping.

- Keep the area of the operator’s cabin and seat clean and tidy. Do not leave parts, tools or other objects in the area of the operator’s seat. These can cause unexpected accidents while you are working.

- Stress and tiredness from poor sitting position and posture.

- Adjust the operator’s seat so that you can sit comfortably with good posture, and all control levers are within easy reach without having to lean or strain your body. Check that you can reach the foot pedals comfortably with your back resting against the back of the seat.

- Accidental operation of the cranes if operated by more than one operator. Passengers may collide with obstructions or be thrown off the machine, or they may cause a hazard by obstructing the operator’s field of view

- Before and during work, nobody other than the operator should sit in the operator’s seat or climb onto the crane

Types of hazards in the workplace

- Slips, trips, and falls when getting on or off the plant.

- Take the following precautions when you get in and off the crane:

- Check that all guards and covers on the machine are fastened correctly. Tighten any loose bolts or repair any damage.

- Wipe off any mud, oil or snow on the steps before you start work.

- Do not jump onto or off the machine.

- Do not hold onto the seat, control box, control levers or anything other than the hand grips provided when you get on or off the machine.

- Do not get on and off the machine while it is moving.

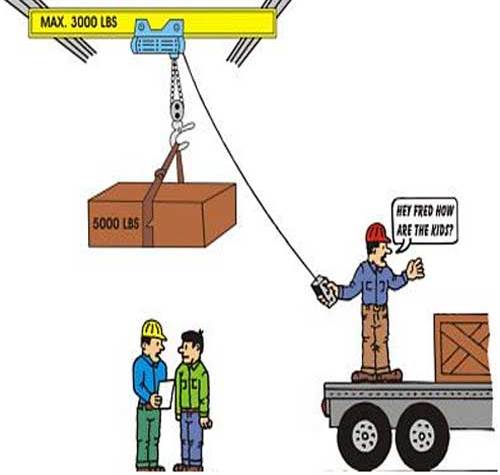

- Dropping of load

- Check safety devices. Pick & Carry cranes are fitted with various safety devices which should be checked before starting work.

- Crane overload or tip over in adverse working configuration.

- Check the operation of the crane computer / Load Moment Indicator (“LMI”) according to the pre-operational check procedure described in the Operators Manual (this manual should be kept in the crane cabin).

- Failure of controls and/or mechanical parts of the crane.

- Before operating the crane check the machine according to the pre-operational checking procedure detailed in this manual. Check the operation of the control levers while the crane is not carrying any load. Allow the crane to warm up before carrying a full load

- Falling objects (during erecting and dismantling activities) could damage property and present a risk of injury to workers and members of the public.

- Erect and maintain effective barricades around the mobile crane. Only allow persons who are directly involved Pick & Carry crane operations inside the area. Schedule the erecting and dismantling of the crane to occur when the movement of other persons and mobile plant at the workplace is at a minimum

PDF and ebooks for lifting operations risk assessment

The book provides readers with a toolbox of techniques that can be used to aid them in analyzing conceptual designs, completed designs, procedures, and operational risk.

It leads readers through a risk assessment and shows them the proper tools to be used at various steps in the process.

It is an important book for professionals that make risk-based decisions for their companies in various industries, including the insurance industry, loss control, forensics, all domains of safety, engineering and technical fields, management science, and decision analysis.

It is also an excellent standalone textbook for a risk assessment or a risk management course.

What are the hazards in crane lifting?

The three most common hazards involving overhead cranes include electrical hazards, overloading, and materials falling/slipping from overhead hoists.

The crane safety checklist covers: Verify visible damage, including cables, crane hooks, stabilizers. etc. Verification of the state of the machine, such as control, brakes, warning signs and more.

The distance is measured from the center pin of the crane to the center of the load. Example: You need to lift a load of 15 tons (30,000 pounds) a distance of 25 feet.

Poor or no maintenance or machines may be used improperly through inexperience or lack of training. Parts of the equipment may fail and loads may drop. Before you start using any equipment you need to think about what risks may occur and how these can be managed.

The most read

Crane Risk Assessment

This General Guide provides information on how to manage the risks of cranes at a workplace.

Heavy Duty equipment

The construction machines are those that allow performing different works in the field of land adaptation.

Heavy Equipment Safety Topics

Any person who operates, leases, rented, or borrowed heavy equipment must take many hours of safety training for each type of equipment.

Job safety analysis for loading and unloading

We can not get rid of danger completely however we can reduce the risk and control it by utilizing normal procedures and good work practices.