What is a tower crane? – Tower cranes are widely used for lifting operations in the construction industry. Tower cranes are a common fixture at any major construction site. They are pretty hard to miss… they often rise hundreds of feet into the air and can reach out just as far. The construction crew uses the tower crane to lift steel, concrete, large tools – like acetylene torches and generators, and a wide variety of other building materials.

What are tower cranes used for?

The operating characteristics of a tower crane are largely determined by its type of mounting, type of tower and type of jib.

Static tower crane

A tower crane with a static base only occupies a limited area but is able to cover, from its fixed position, all points at which loads are to be handled within the maximum slewing radius. They can be set at varying heights up to their maximum free-standing height. They can also be extended beyond this limit by tying the crane back to the supporting structure.

Rail mounted tower crane

Rail-mounted tower cranes have a larger area of coverage as they can travel along their tracks carrying their rated loads. However, the height requirement should not exceed the free-standing height as recommended by the manufacturer.

On the other hand, the crane service would be disrupted whenever work must be done on or near the track. The advantage of mobile tower cranes lies in great inward reach without the long jib which would normally be required to reach over the top of the structure.

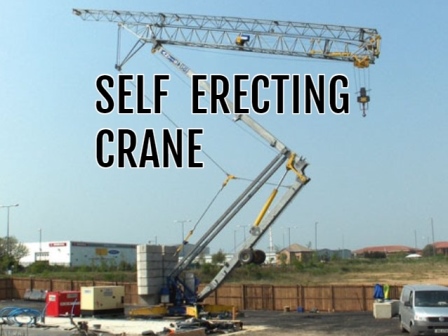

Self erecting crane

Generally, truck-mounted tower cranes are completely self-contained and can be driven along roads. They are generally capable of comparatively rapid erection and dismantling. They are however generally unable to travel in their fully erected state and cannot handle loads while traveling.

Crawling tower crane

Crawler-mounted tower cranes are required to be transported on a low-loader or towed on special road axles when traveling on public roads. Inside the workplace, some can travel over a firm, flat, level ground carrying loads up to a specified proportion of their rated loads.

They are also able to travel in a partially erected state but without load over unprepared ground provided it is within certain limits of level and compaction.

Tower crane jib

A horizontal trolley jib usually has a smaller minimum operating radius than the equivalent luffing jib and is thus able to handle loads closer to the tower of the crane. For a given height of the tower, however, a greater height of lift is available with a luffing jib, and the jib can be raised or lowered to clear obstacles. One advantage of a fixed luff jib is that its extra height at the jib head enables it to clear objects that would obstruct a horizontal trolley jib. The advantage of a rear-pivoted luffing jib is that it has a smaller minimum hook radius than an ordinary luffing jib.

Articulated jib crane

For articulated jibs, some designs are not required to weather vane. In this case, the crane is made to withstand storm winds with the jib drawn into minimum radius; there is then no need for a 360° obstruction-free slewing path. One type of this crane has a hinged jib arranged so that the outer portion remains horizontal. As the jib is folded, the outer portion rises, giving increased height and the ability to pass over obstructions.

What type of crane do I need?

The selection of a crane for any job should be made only after a thorough examination of all the factors involved. In general, it is good practice to select a machine that has a working margin in respect of the load capacity and other anticipated requirements.

The crane should have a permanent durable plate bearing the manufacturer’s name, machine model, serial number, year of manufacture and weight of the unit for identification purposes.

Every major structural, electrical and mechanical component of the machine should have a permanent durable plate or a clear indication bearing the manufacturers’ name, machine model number, serial number, year of an original sale by the manufacturer and weight of the unit.

Besides, identification numbers should be clearly marked on all basic removable components and attachments of the machine (such as counterweights, etc.) to show that they belong to that machine. It is important that these components should be used only on that machine or identical models or equipment for which they were specifically intended by the manufacturer.

What is a tower crane?

The tower crane is a fixed Crane and has to be mounted On-Site. The Tower Crane presents itself like a vertical metallic structure having a horizontal boom that can turn over an angle up to 360°.

Tower cranes are mainly fixed on construction sites. Construction sites use tower cranes from large tools such as lift steel, concrete, acetylene torch and generators, and a variety of other building materials. Tower cranes are mainly used to transport and lift capacity from one place to another.

A common “rule of thumb” is considering stopping the crane if the wind speed reaches 20 mph. Project managers and Appointed persons should reconsider lifts if the wind speed increases dangerously, even before it reaches 20 mph.

The most read

Tower Crane Equipment

A tower crane is a construction machine designed to load and unload different materials. This load is distributed through the use of a hook that remains suspended thanks to the use of a cable.

Self Erecting mobile Tower Cranes

Self-erecting tower cranes have long been commonplace in Europe. Their versatility and reliability have made them a mainstay on the European Jobsite.