The transport of bulk cargo or materials with volume that exceed the capacity of a container needs to be handled by special cranes, with rigging and fastening mechanisms to move within warehouses, ports or work stations.

Port cranes types

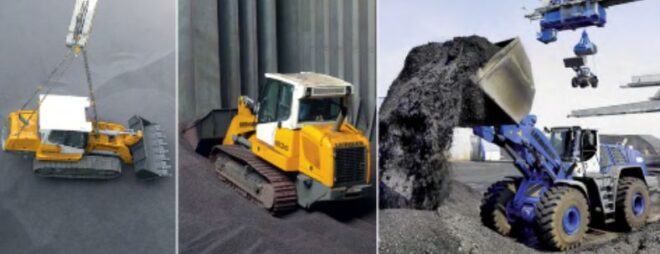

Crawler Crane

The wide range of equipment and accessories available allows them to convert them quickly and without difficulty in machines suitable for handling bulk and other cargo.

These special cranes have another advantage: reduced operating costs. For use in port facilities, a package of accessories for special cranes is supplied in order to adapt the machine to the specific loading and unloading needs of the boats in the docks.

Said package includes:

- An elevated operator’s cabin to obtain a complete view of the warehouse.

- An adapter between the lower chassis of the crane and the superstructure to raise the boom reference point. This allows a more efficient work close to the boat and guarantees that the crane can operate in a minimum range and therefore very close to its maximum load capacity.

- Multiple safety features that include protections on the access stairs, wide service walkways throughout the superstructure, more mirrors for a clean and complete view and an acoustic warning sign of translation.

- The modern Litronic® control system is included as a standard feature.

- Accurate on-line calculation of the load moment to favor the maximum use of the available load capacities.

Load Manipulator

The main characteristics of these machines are a long reach, high lifting capacity, and extraordinary stability.

- The variety of uses so different from each other requires a wide range of models. There are numerous variants of lower chassis, combinations of attached elements, work tools, and quick-change systems, as well as a large selection of equipment, which allows each machine to adapt to specific uses and requirements.

- Low fuel consumption with intelligent machine control: with the energy efficiency system, the interaction of the drive components is optimized in terms of efficiency. Thus, the LPE allows the use of the machine in the range of lower fuel consumption specified while increasing efficiency and maintaining performance.

- Power, speed, and precision: handling machines guarantee maximum productivity and performance. The excellent interaction between the engine, the hydraulic components, and the electronic ones leads to precision and precise control, all with fast and energetic movements.

- Excellent panoramic vision: the large glazed surfaces, the different lift versions of the cab and the lateral and rear monitoring systems give the operator unbeatable visibility of the work area and the environment of the machine. This perfect view reinforces operator safety and maneuvers at all times

Chainloader

Other special cranes are the loaders of chains are used in the discharges of ships as compact universal devices to distribute the load, for example, corn or sugar, inside the hull of the ship.

- Thanks to the drive on chains, the loaders of chains can fulfill his service even in the most extreme working conditions.

- Its great maneuverability is an important advantage, especially in reduced workspaces such as the deck of a boat

- The Z-arm kinematics of the lifting arm, together with the working hydraulics, enables high performance

Wheel Loaders

In ports, the wheel loaders are used to transport loads, to unload ships and to load trucks and freight trains.

- The loaders of the big range and those of the medium range are characterized by their profitability.

- With the same working conditions, they consume up to 25% less fuel.

- Even in extreme working conditions, the traction system is always hydraulically regulated.

- The mechanical service brake only acts as a support, so it remains virtually wear-free

- The traction force can be regulated gradually, which prevents the wheels from turning and, with it, the wear of them by up to 25%.

- Stereo loaders are especially powerful and safe.

- The unique steering system combines oscillating steering with the rear axle.

- This not only increases the maneuverability of the machine by 20% but also provides extraordinary stability, since the oscillating angle is only 30 ° instead of the usual 40 ° in conventional oscillating directions.

- At the same time, this makes it possible to transport large loads without having to increase the operating weight of the machine

A crane that is used for handling containers

The cranes used to handle containers are specialized cranes located in a dock, port or warehouse and used to load and unload cargo containers on board or on land.

Container cranes on land are usually equipped with a telescopic spreader to handle containers of different sizes, and the cranes for unloading containers from ships are STS cranes.

Freight Transportation

To flexibly handle individual and bulk loads, we offer a complete range of equipment and special port cranes to handle loads, as well as multiple machines specially modified for such operations such as:

- cranes on hydraulic chains

- handling machines

- hydraulic excavators

- wheel loaders

- loaders on chains

How do shipping container cranes work?

A crane is a piece of heavy machinery that is a tower or platform that is equipped with cables and pulleys. They are used to lift and lower materials. The most common use of cranes is in the construction industry, ports and airports, and heavy equipment manufacturing.

A gantry crane is a crane built atop a gantry, which is a structure used to straddle an object or workspace. The terms gantry crane and overhead crane (or bridge crane) are often used interchangeably, as both types of crane straddle their workload.

At ports that use straddle carriers, the ship-to-shore gantry cranes place containers directly on the dock. The carrier then straddles the boxes, picks them up and takes them to the yard.

The crane is operated by a specially trained crane operator from within the cabin located on the top end of the crane and suspended from the trolley. It is the operator who lifts the container from the ship or dock for unloading or loading of cargo. The modern built spreader can lift up to 4 containers together.

The most read

Container Crane

Container cranes consist of a supporting framework that can traverse the length of a quay or yard on a rail track. Instead of a hook, they are equipped with a specialized handling tool called a spreader.

Straddle Carrier

Globalization combined with the success of containerization has brought about tremendous increases in the transportation of containers across the world.