A tower crane is a construction machine designed to load and unload different materials. This load is distributed through the use of a hook that remains suspended thanks to the use of a cable. This heavy machine is essential in the work of modern construction.

In addition, it performs its corresponding displacement on a car and has rotating support that is usually mounted on top of a vertical tower.

A common modern engineering technique is to fix the crane to the liftshaft site – lifting it to higher elevations as the construction progresses – and ending the well once the crane has been dismantled.

The tower crane is often secured to the ground within the structure, where the space around the building is limited.

Tower crane specifications

- The crane has a base that is attached to the bottom of said tower.

- Uploads and downloads made with great frequency

- Make many transfers between various locations.

- Where the tower crane is most used are the construction works,

- They have the ability to reach great heights.

Tower crane mast

Tower Crane Parts – The tower crane is composed of several parts that are fundamental to perform the work in the construction of a work, these parts are:

It is a metal lattice structure with a normally square section, whose main mission is to provide the tower crane with sufficient height.

Normally it is formed by lattice modules that facilitate the transport of the crane. For assembly, these modules will be joined by screws, all of which will be connected to the projected height. Its shape and dimension vary according to the necessary characteristics of weight and height.

In the upper part of the mast is the rotating area that gives the crane a 360º horizontal movement. Also depending on the model, you can have a cabin for its operation by an operator.

Tower crane counterweight

They are structures of concrete prefabricated that are placed to stabilize the weight and inertia that occurs in the arrow of the crane. They must stabilize the crane both at rest and in operation. Both these blocks and those that form the ballast must have identified their weight legibly and indelibly.

Tower crane jib

It is a metal lattice structure of a normally triangular section, whose main mission is to provide the crane with the necessary radius or range. It is also called a jib. Like the mast, it usually has a modular structure to facilitate its transport.

To move the specialized personnel during the assembly, revision and maintenance work along the arrow, there will be a longitudinal element, a safety cable, to which the safety belt carabiner can be attached.

Tower crane counter jib

The length of the counterjib oscillates between 30 and 35% of the length of the pen. At the end of the counterjib, the counterweights are placed. It is attached to the mast in the area opposite the union with the arrow.

It is formed a robust base formed by several metal profiles, forming on them a kind of catwalk to facilitate the passage of personnel from the mast to the counterweights. The sections of the profiles will depend on the counterweights that will be placed.

Central ballast

It can be formed by a buried shoe or by several pieces of prefabricated concrete at the base of the crane.

Its mission is to stabilize the crane against its own weight, the weight it can transfer and the adverse environmental conditions

Crane trolley

It consists of a car that moves along the arrow through some lanes. This movement gives the necessary maneuverability in the tower crane. It is metallic so that it supports the weight to be lifted.

Crane hook

Cables and hook: The lifting cable is one of the most delicate parts of the crane and, to give an adequate performance, it must be used and maintained correctly.

It must be perfectly tensioned and a periodic follow-up will be carried out so that, during its winding in the drum, it does not cross over, as it would cause crushing.

Tower crane motor specifications

The most generic tower crane consists of four electric motors:

- Lifting motor: allows vertical movement of the load.

- Distribution motor: gives the movement of the car along the jib.

- Motor of orientation: it allows the rotation of 360º, in the horizontal plane, of the upper structure of the crane.

- Translational motor: displacement of the crane, as a whole, on rails. To perform this movement it is necessary that the crane is at rest.

The tower of the crane can be embedded in the ground, immobilized without wheels or movable on straight or curved tracks. Assembly operations must be carried out by specialized personnel.

Likewise, the maintenance and conservation operations will be carried out in accordance with the standards given by the manufacturer.

Movable tower crane

Is one whose base is equipped with own means of translation on rails or other means and whose maximum height of assembly is such that without any additional anchoring means is stable both in service and out of service, for the solicitations to which it goes to be submitted

Fixed tower crane

Its base does not possess means of translation or, being possessed, they are not usable on the site. They are those in which the base is a foundation or any other fixed set.

Mobile tower crane

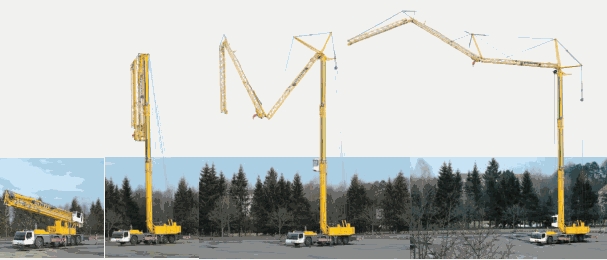

Removable single-body tower crane: Temporary installation designed for frequent assemblies, disassemblies, and transfers.

Self erecting tower crane

Tower crane whose tower is constituted by a single block and that does not require additional structural elements for its installation. It can be provided with wheels to facilitate its movement.

Climbing tower crane

The climbing tower crane is an auxiliary means for lifting loads.

It is installed on the structure of work under construction and moves from bottom to top by its own means; to the rhythm and as the construction progresses.

crane operator

Tower crane operators use tower cranes to lift, move, position and place materials and equipment.

They calculate the lifting capacity of the crane and determine the weight of the load, participate in the configuration and disassembly of the crane and place and stabilize the crane before lifting.

They also perform regular inspections, and minor repairs and equipment maintenance

Tasks and work tasks for: “Crane and tower operator”.

- Determine the load weights and compare them with the lifting capacities to avoid overloads.

- directs direct aides dedicated to the placement of blocking and stabilization under the cranes.

- Load and unload the packages from the trucks and move the containers to the storage containers.

- Move the levers, press the pedals and turn the dials to operate electromagnets or other mobile equipment to lift, move and place loads.

- Review daily work and delivery schedules to determine orders, delivery sequences, and special loading instructions.

- Weigh the packages, using floor scales and record the weights for the company records.

- It cleans, lubricates and maintains mechanisms such as cables, pulleys, and gripping devices, making the necessary repairs.

- It directs the truck drivers who drive the vehicles back to the loading bays and secures the loads for delivery.

- Inspect and adjust the mechanisms of the crane and lifting accessories to avoid breakdowns and damage.

- Inspect the cargo packing to verify that it complies with the regulations and customer requirements.

- Inspect the cables and gripping devices for wear, and install or replace the cables as necessary.

operator crane tower

How much can a tower crane lift?

The maximum load that the crane can lift is 18 metric tons, but the crane cannot lift that much weight if the load is positioned at the end of the jib. The closer the load is positioned to the mast, the more weight the crane can lift safely. The 300 tonne-meter rating tells you the relationship.

Tower crane mast

Tower crane jib

Tower crane counter jib

Tower crane counterweight

Central ballast

Crane trolley

Crane hook

Motor crane

The base is bolted to a large concrete pad that supports the crane. The base connects to the mast (or tower), which gives the tower crane its height. Attached to the top of the mast is the slewing unit, the gear, and motor, that allows the crane to rotate.

The biggest difference between mobile cranes and tower or fixed cranes is their mobility. As their names suggest, fixed cranes are fixed to a single spot once they have been set up. Whereas, mobile cranes can be moved as needed. The mobility of a mobile crane holds many advantages for any construction site.

When high-rise structures are being constructed temporary cranes are erected which quickly pose a hazard to airborne traffic.

Tower cranes are widely used for lifting operations in the construction industry. Statistics show that tower cranes contribute to quite a number of serious accidents. Property damage and bodily injuries can be avoided if they are properly used.

The most read

Types of Tower Cranes

Types and designs of cranes for construction and industry: Flat Top, Hammerhead, Luffing crane, self-erecting, etc.

Tower Crane Specifications

The study of the tower crane will include knowing the structures that make it up, as well as knowing the elements that are part of this and that will allow the crane to perform the tasks for which it has been designed.