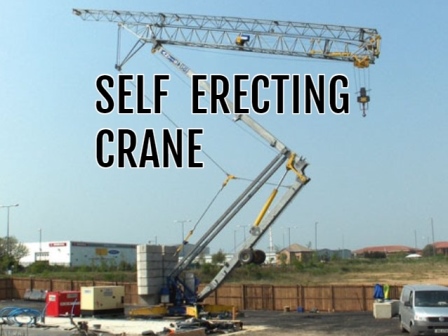

A self-erecting tower crane is compact, easy to erect and operate, and has several transport options. Wireless remote controls, quiet and efficient electric motors, state-of-the-art variable frequency motor drives, and overload protection systems are standard.

Self-erect portable tower cranes

The Self-erect portable tower cranes represent a new type of technology, which is increasingly utilized in Europe to construct and service low to mid-rise buildings.

Despite the similar name, self-erecting tower cranes are not assembled or operated as traditional high-rise tower cranes. Self-erecting tower cranes are driven to the Jobsite and can be set up in under an hour by unfolding in a controlled sequence.

They provide good reach and lifting capacity while having a small footprint, making them suited to operating within tight spaces.

The current crane regulations do not address self-erecting tower cranes. It is recommended that develop a regulatory and licensing system specific to self-erecting tower cranes. This will enable the industry to utilize the flexibility and efficiencies offered by self-erecting tower cranes while ensuring safe operation.

Self erecting tower crane specifications

Benefits of using a Self Erecting Tower Crane: (SETC)

- Self Erecting Tower Cranes (SETCs) are all operated by radio remote control, allowing the Crane Operator the flexibility to move with his load and deliver it exactly to where it is required.

- SETC will improve productivity by delivering the material exactly to point of use thus reducing additional labor costs.

- SETC occupies a small footprint and could service your site from the one location, giving you more storage space for materials.

- SETC can reduce the requirement for vehicle movements on-site and also reduce the amount of material handling on-site, thus increasing site safety whilst saving you money.

Mobile Tower Crane

Tower cranes are mounted on a mast and fixed in place. They are divided into two general categories:

- Luffing boom: A tower crane with a boom that can be raised or lowered

- Hammerhead: A tower crane with a horizontal boom equipped with a trolley that can traverse the boom.

A hammerhead tower crane as the building under construction rises, new mast sections can be added to the tower crane to increase its height, a process known as jumping. A jump can take up to a day.

Separate from the traditional types of tower cranes described above, manufacturers are introducing new technology, the self-erecting tower crane.

Despite the similar name, self-erecting tower crane is not assembled or operated as a traditional high-rise tower crane.

Self-erecting tower cranes are driven to the Jobsite and can be set up in a short amount of time by unfolding in a controlled sequence. They provide good reach and lifting capacity while having a small footprint, making them suited to operating within tight spaces. Unlike traditional tower cranes, currently available models of self-erecting tower cranes are limited in height and cannot be jumped to a newer height.

Self-erecting tower cranes are not common in the United States but are increasingly utilized in Europe to construct and service low to mid-rise buildings.

Self erecting mobile tower cranes

Self-erecting tower cranes (SETCs) have become increasingly popular on small construction sites where the size of the project does not justify the installation of a conventional top slew tower crane. The management of the installation and use of self-erecting tower cranes follows exactly the same principles as top slew tower cranes.

The details, however, vary between the two generic types and the purpose of this Best Practice Guide is to provide guidance on the safe siting, erection, use, maintenance, thorough examination, and dismantling of SETCs, together with the management and planning of these activities.

Self erecting tower

In addition to Self-erecting tower cranes -SETCs- that are towed or transported to the site on a vehicle, truck-mounted tower cranes have become popular in the UK over the past few years. These cranes, which have many of the attributes of the self-erecting tower crane, are permanently mounted on a mobile crane carrier chassis and in operational requirements fall between SETCs and conventional mobile cranes. This Best Practice Guide does not address many aspects of truck-mounted tower crane operation.

This distinct type of crane will be covered by a future Best Practice Guide SETCs are sometimes referred to as “pedestrian operated tower cranes”. This may not always be correct, as although the majority of SETCs are operated with the operator standing on the ground adjacent to the crane using remote controls, some are provided with cabs at a high level or operating stations at the base. It is also possible for some conventional top-slew tower cranes to be operated by remote controls at ground level.

Erecting a tower crane

The crane supplier/manufacturer will be able to advise on the maximum in-service and out-of-service wind conditions for the specific model of a crane to be used.

The out-of-service wind loadings will often be much greater than the in-service loads and the load-bearing capability of the ground (foundation) must be sufficient for the extra imposed loads due to the out-of-service wind. Where the SETC is to be taken down when high winds are anticipated, the operator must be made aware of any wind speed restrictions for dismantling.

There have been a number of accidents where the ground conditions were not suitable for the out-of-service loadings or SETC have been dismantled at wind speeds in excess of the manufacturer’s maximum recommended speeds.

SETC’s should be left in free slew when out of service to allow the crane to “weathervane”, to ensure that the out-of-service foundation loads are not exceeded.

The Approved Code of Practice to LOLER says that “Where lifting equipment, and/or its load, may be affected by the high wind the equipment should be fitted with appropriate devices so as to detect dangerous situations and allow measures to be taken to cease using the equipment”. Consequently, all SETCs should be fitted with an anemometer (many new cranes are now supplied with an anemometer as a standard fitting). A record of wind speed monitoring should be kept and electronic wind recording systems are now available for this task.

All operating personnel should be aware of wind speed action levels for the particular crane in use. It is important to note that the maximum wind speed at which the jib of an SETC can be safely folded back is often lower than the maximum in-service wind speed. Ignoring this has led to a number of accidents.

Self erecting crane hire

The area in which a self-erecting tower crane -SETC- is to be sited must be carefully assessed to ensure that it is suitable before the crane is taken to the site and put into service. During this assessment, the following points should be considered.

Tower crane clearance requirements

The area chosen must be of sufficient size to enable the SETC to be maneuvered into position, set up, operated, and dismantled, with sufficient clearances between the crane and surrounding structures, as detailed in the manufacture’s operation and instruction manual. This is to ensure that trapping points are not created and that damage does not occur to either the crane or the surrounding structures (including the building under construction).

Tower crane installation

Insufficient consideration and assessment of ground conditions have been found to be a major cause of accidents with self-erecting tower crane -SETC-.

All SETCs rely for their stability on the ability of the ground on which they are standing to safely absorb the loads imposed by the crane. Most SETC manufacturers supply information on the loads imposed by the crane on the ground in the various operating and set-up configurations of the crane.

These generally consist of :

- Maximum vertical load per stabilizer

- Maximum horizontal reactions

- Dimensions of the stabilizer support plate (pad)

- Ground-level pressure under the stabilizer support plate

Ground conditions in the construction

An assessment of the ability of the ground to accept these loads should be made by a competent person.

This assessment may indicate that the ground has the insufficient bearing capacity to accept the loads imposed by the crane, in which case additional measures will need to be taken before the crane can be set up. These may include using timber sleepers, proprietary mats or concrete pads to spread the applied load to an acceptable bearing pressure.

In extreme circumstances, piled foundations may be required. Wherever a concrete pad, steel grillage or piled foundation is constructed to accept the loads from an SETC, the contractor constructing the foundation should complete a foundation completion form to certify that the foundation has been correctly designed and constructed before the erection of the crane starts.

Where timber is to be used it is important that the timber sections employed are of sufficient dimensions and strength to transmit the applied loads to the ground and that the timbers are pinned together to form a grillage. The use of individual loose timbers has been found to be a major cause of accidents.

When siting the crane, consideration should be given to the length of time that the crane will be erected in one position and the likely deterioration of the supporting ground or foundation over time (e.g. timber rotting, undermining by water or frost, drying out, adjacent excavations).

Tower cranes and trespass to airspace

If the siting of the crane will result in oversailing of an adjacent property, not in control of the Principal Contractor, oversailing rights must be obtained in advance by the Principal Contractor (hirer).

Consideration needs to be given to inadvertent oversailing whilst the crane is left, when not in use, in free slew. Should the crane need to be guyed, tethered, or the slew locked, when out of service this must be considered at the initial planning stage and foundation loads for the specific configuration obtained from the manufacturer.

This information must be provided to the hirer and included in both the erection and use method statements. Cranes should not be left in a part erected condition overnight ( i.e. jib partially folded back) unless allowed for in the manufacturer’s manual or without prior written approval from the crane manufacturer.

Tower crane air rights

A self-erecting tower crane was erected on a site adjacent to a row of occupied houses. Over the first weekend, the occupants of the houses became alarmed when the crane, which had been left in free slew, moved over their houses. Their concern was heightened by the presence of a generator slung from the hook. A complaint to the Health and Safety Executive resulted in a prohibition notice being served on the construction company.

Where the crane’s jib and/or mast is to be folded to avoid oversailing when out of service the operator must be competent to carry out this procedure. The maintenance schedule for the crane will need to be adjusted accordingly.

What is a self erecting tower crane?

A Self Erecting Tower Crane (SETC) is a Tower Crane that can be easily inserted on a site with restricted space in a short period of time. These cranes operate from a fixed position and must be safely placed on-site by qualified field engineers familiar with the mechanisms that they are using.

Hans Liebherr helped develop the mobile tower crane in the late 1940s with the help of a team of design engineers.

They invented the very first mobile tower crane, which was, as its name would suggest, a crane that construction companies could move around while still enjoying the benefits of the tower crane.

Tower cranes are widely used for lifting operations in the construction industry. Statistics show that tower cranes contribute to quite a number of serious accidents. Property damage and bodily injuries can be avoided if they are properly used.

This crane safety checklist covers:

-Checking and inspecting the area of operation

-Checking for visible damages including wire ropes, crane hook, outriggers. etc.

-Checking the machine condition such as control, brakes, warning signs and more

-Checking for adequate housekeeping and other machinery house inspection

The most read

Self erecting tower crane specifications

Tower Crane and Construction: installation, how to build a tower crane, tower crane assembly procedure, tower crane dismantling method statement.

Self Erecting Crane Rental

- How much does it cost to hire a tower crane?

- How much does a self-erecting crane operator make?

Erecting a Tower Crane

Self Erecting tower cranes are changing the nature of residential home building projects across North America.

Mobile Tower Crane

It is the combination of a self-propelled tower crane and a mobile crane.