Heavy Equipment Safety Topics: Any person who operates, leased, rented, or borrowed heavy equipment (regardless of job series) must take many hours of safety training for each type of equipment before they operate the equipment. This training includes 3 hours of pre-class study, 4 hours of classroom instruction, and at minimum, 1 hour of equipment operation to demonstrate their ability to apply the safe heavy equipment operating procedures for the terrain and conditions in their area.

Heavy equipment safety training

After completing the training, the operator must demonstrate through written exams and a pass/fail instructor evaluation the following knowledge and skills:

- The Operator’s Manual

- Proper methods of fueling, maintenance, and lubrication as required by the manufacturer

- Pre-start procedures, which include proper safety checks

- Starting and warming up the machine

- Proper operational procedures, which include the use of all controls

- Demonstration of travel maneuvers necessary for the types of terrain they will encounter

- Proper hook-up of equipment and attachments that may be used with the machine

- Operation of the equipment with various attachments

- Proper shut-down procedures

- Proper transportation and load securement procedures

- Proper personal protective equipment

- Service policy as it pertains to heavy equipment

Currently, there are 11 types of equipment for which has developed a safety training program. They are:

- Motor grader,

- Self-propelled scraper pan,

- Skid steer,

- Agricultural tractor,

- Crawler dozer,

- Crawler loader,

- Wheeled loader,

- Powered industrial trucks (forklift) Classes 1-7,

- Excavator,

- Backhoe/loader, and

- Specialty tracked equipment.

Heavy equipment operator

A heavy equipment operator is An employee or volunteer who operates heavy-duty equipment and whose operator duties are specifically mentioned in his or her position description or An individual identified in a Service written agreement (e.g., Memorandum of Understanding) who operates Service heavy equipment.

Heavy Equipment Safety Topics : Is refresher training required?

Beginning in 2012, operators must take refresher training for each type of equipment they operate every 3 years. The Regional Heavy Equipment Coordinator coordinates the web-based refresher training program.

This program requires an additional component of supervised equipment operation for those employees who have not operated that type of equipment within the past 3 years and for those employees who have exhibited a deficiency in their competency to operate the equipment. The operator’s supervisor and the Regional Heavy Equipment Coordinator determine if the operator needs to successfully complete an operational requirement.

- Construction Equipment Hauling

- Construction Safety and Health

- Objectives of Construction Management

- Mining Equipment Manufacturers

Mechanical hazard

Machinery and equipment have moving parts. The action of moving parts may have sufficient force in motion to cause injury to people. When assessing machinery and equipment for possible mechanical hazards, consider:

- machinery and equipment with moving parts that can be reached by people

- machinery and equipment that can eject objects (parts, components, products or waste items) that may strike a person with sufficient force to cause harm

- machinery and equipment with moving parts that can reach people, such as booms or mechanical appendages (arms)

- mobile machinery and equipment, such as forklifts, pallet jacks, earthmoving equipment, operated in areas where people may gain access.

Types of heavy equipment

The use of heavy equipment is an important part of residential, commercial, and roadway construction and maintenance operations. A variety of heavy equipment is used in construction and maintenance.

Heavy equipment can be classified into the following categories based on the type of operation:

- excavating equipment

- lifting equipment

- loading and hauling equipment

- compaction equipment

- grading and finishing equipment

- paving and surface treatment equipment

Depending upon their versatility, heavy equipment may be used for multiple purposes. For example, backhoes are normally used for excavating but they can also load the excavated materials into trucks.

Safety tips for working around heavy equipment

Heavy equipment or earth moving machines have been recently reported due to multiple accidents and fatalities. It is a must that all operators have identifiable and verifiable training on the equipment before operating. Accidents can happen to both newly trained and seasoned veterans.

Mounting and dismounting heavy equipment

Falls and stepping on and off are some of the biggest causes of injury recorded by OSHA and other safety departments. This includes entering and exiting the cab of a machine. A good rule of thumb is to always maintain a 3 point contact when getting on or off of your equipment and never jump.

The three Point Rule requires three of four points of contact to be maintained with the vehicle at all times – two hands and one foot, or both feet and one hand. If handholds or steps are damaged, replace them, it could prevent major injury over time.

Heavy equipment seat belts

Wearing your seatbelt in heavy equipment is just as important as in a moving motor vehicle. There is no excuse but laziness for not wearing it at all times. Not only will it save your life in the case of a rollover, but it also keeps you firmly in your seat when operating on rough terrain, saving energy and reducing close calls by the end of a long day.

Workplace safety topics for meetings

Communication: Always be in constant communication with the people working around you. A two-way radio is the best form of communication if that option is not available then use hand signals from a spotter who has been properly trained. Communication with operators should be touched upon at every safety meeting and reinforced by the foreman on site.

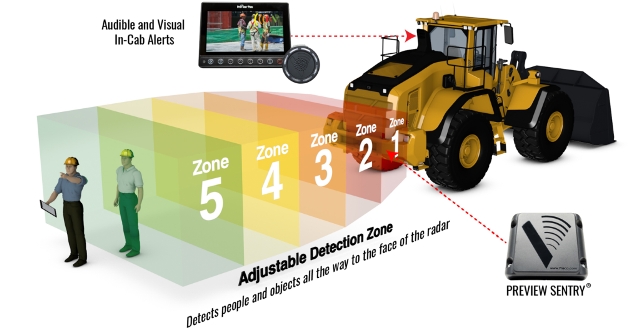

Heavy equipment blind spots

Heavy equipment operators have to be 100% sure that no one is behind them or in their blind spots when moving, even if this involves getting out of the machine and checking.

If vision is limited, have a spotter stand in a safe, visible position to guide and direct you. Inform those working around you for the day of your blind spots and require them to make eye contact with you before coming into the equipment’s vicinity. High visibility vests are mandatory on all sites.

Heavy equipment inspection checklist

Equipment should be inspected at least once daily before operating. This involves walking around with a pre-developed checklist of components to check for good working order.

Hydraulic hoses, undercarriage, oil levels, stress points, etc. are all areas that need to be inspected and reported to the maintenance/safety department before machine start-up. Using a cloud-based mobile device to complete a task such as this can greatly improve communication and response time between operator and mechanic.

Heavy equipment load securement

Load Limits: Be aware of the load limits of varying equipment when operating different machines throughout the day. Depending on the equipment set-up and size the load limits can change drastically.

When lifting objects with a machine make sure loads are secure with the proper rigging attachments, and always inspect to ensure they are in good working condition. As with most equipment operations, confirm all workers are at a safe distance when lifting and moving loads.

Heavy equipment hazards

Overhead and Underground Hazards: Before work starts on any jobsite, all over-head obstructions such as power lines and low clearance should be identified and flagged. Underground utilities such as water, sewer, gas, and electrical need to be located by the appropriate department and marked with color-coded paint. Play it safe when getting close to the underground utility and hand dig to uncover. When leaving dugout holes that workers or the public can fall in to, be sure to set up barriers and snow fencing.

Heavy-duty truck ramps

Loading/Unloading Equipment: Always be sure to be on level ground when loading or unloading your equipment. It greatly reduces the risk of rollovers or sliding off the low-bed ramps. If you are unloading on a busy jobsite or high traffic area, make sure people are clear of the unloading area and use a spotter to guide you.

Job hazard analysis heavy equipment operator

Heavy Equipment Hazards: The use of heavy equipment on a Jobsite is vital and necessary to the overall success of the construction project. However, unauthorized or unwise use of heavy equipment can result in personal injury, loss of life, or severe loss to materials needed to complete the project. Today we will discuss some key points to keep in mind when working around heavy equipment.

- Poor Repair or Service: Poor repair or service of the equipment is a common hazard. Poor repair may include repairing by an unauthorized person. Such repairs or servicing of equipment may jeopardize the safety of operators and others due to the mechanical failure of heavy equipment.

- Obstructed View While Backing: Due to the size of heavy equipment, equipment operators have obstructed the view and blind spots while backing. Dirty or broken windows may also block an operator’s view of people or objects posing potential hazards.

- Striking People and Collision with Other Equipment: Heavy equipment usually operates in close proximity to other heavy equipment and on-foot workers. The path of the equipment within the workspace constantly changes. The interactions between the heavy equipment and on-foot workers are not always coordinated.

- Caught Between Equipment and Objects: Many incidents have occurred in work areas where on-foot workers are caught between heavy equipment and other fixed objects or crushed between the equipment. This happens more often when the turning radius for the equipment or trucks is not wide enough at the entry and exit points of the workspace within the work zone.

Heavy equipment driver

- Riders Falling Off Equipment or Buckets: Although not permitted, the casual riding of the equipment by workers (other than the operators) has been the cause of many construction workplace accidents.

- Overturning of Equipment: Overturning of equipment can occur when the load on the equipment is more than the capacity of the equipment. Overturning also occurs when one side of the equipment is on unstable or loose ground or in a depressed area.

- Driving at Excessive Speeds: Heavy equipment is not designed for excessive speeds. However, if they are not loaded, the operators may have a tendency to drive at higher than normal speeds causing hazards to on foot workers and others on site.

- Unexpected Electrical Shock: Heavy equipment can come in contact with overhead and underground power lines that cause electrical shock or electrocution.

- Failure of Lifting Mechanisms/Operational Failures: Such failures can occur in lifting equipment either due to the mechanical failure or lack of proper knowledge of the lifting mechanism.

- Injuries to Operators Due to Ingress/Egress Difficulties: Poor ergonomic design and improper ingress and egress practices (e.g. jumping out of the cab instead of coming down slowly) can cause injuries to equipment operators.

- Runaway Machines: Runaway occurs when the wheels are not blocked upon parking or when operators are not able to control the equipment. Parking along a steep surface without proper blocks on the downgrade side of wheels will most likely cause such a hazard.

- Overhead Obstructions: Being struck by limbs of trees or other overhead obstructions, and moving equipment can occur when the operators are unaware of the limbs of trees or other fixed overhead objects. Another cause of such hazard can be due to the poor judgment of operators on the horizontal and vertical clearances.

Heavy Equipment Safety topics

Whether it’s a tractor, bulldozer, forklift, excavator, paver, milling machine, etc., working around heavy equipment adds a new level of danger to workers. Statistics show that approximately 75% of all “struck by” and “run over” fatalities in the construction industry involve the use of heavy equipment.

This is the most important rule: Work at a safe distance from all power lines. The Occupational Safety and Health Administration (OSHA) requires that equipment be kept at least 10 feet away from power lines from 0-50 kV.

Safety Equipment, as implied by its name, includes the gadgets that are used (worn, used, suspended, etc.) for the protection of life and to avoid injuries or casualties.

A Toolbox Talk is an informal safety meeting that focuses on safety topics related to the specific job, such as workplace hazards and safe work practices. Meetings are normally short in duration and are generally conducted at the job site prior to the commencement of a job or work shift.

The most read

Job safety analysis for loading and unloading

The risk of damage is an inherent part of most industries and initiatives. We can not get rid of danger completely however we can reduce the risk and control it utilizing normal procedures and good work practices.

Heavy Equipment Transport

Unlike shipping standard freight, heavy equipment transport requires special handling, oversize load permits, and special freight carriers.