Forklift Lifting Capacity: limits and driving of loading and unloading, operator and handling in workshop, plant, counterweight, operator, transport.

- What useful load can forklifts transport?

- What minimum requirements are necessary for a forklift?

- And for the industry?

Forklifts are one of the main solutions to transport both objects and loading pallets, saving different stories high.

One of the main characteristics of this type of elevator is undoubtedly its great versatility and is that both those that are intended for cargo transport, such as those used in shops or industries to transport objects of different volumes and weights are achieved according to the needs of the client.

In this way, we can find from small lifts to large lifts with enough dimensions to transport even large volumes of cargo.

Forklift weight capacity

Forklifts have different capacity ranges for good reasons. The problem is that forklift operators sometimes mistakenly judge the load capacity of the machine.

They have seen some forklifts handle very heavy loads, so they generalize that capacity to any forklift. However, this can trigger a catastrophe.

Forklift capacity chart

Warehouse forklift types

The greatest danger to the safety of operators is the same characteristic that makes forklifts so popular.

Its ability to lift and transport almost any type of load, within its weight capacities.

But the problem is in the instability of the forklift once it has a very heavy load on board.

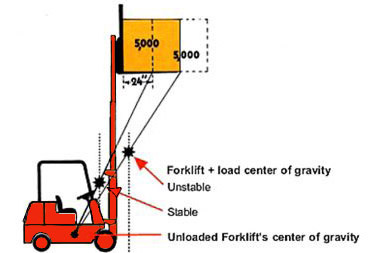

When the load exceeds the capacity of the forklift, the machine becomes quite unstable, with a variable center of gravity that, unless handled with exceptional care, can cause it to overturn and begin the problems.

Other dangerous factors are the incorrect use of restrictions to secure the load and a sudden change in speed or movement that causes the load to move, causing the forklift to lose its balance.

Of course, there are other reasons for the thousands of accidents that occur each year, but almost all forklift accidents, minor or fatal, could have been avoided if the driver had received training and had respected the safety rules understanding the relationship between the counterweight and the load weight

Forklift counterweight

The own weight of the forklift serves as a counterbalance to balance the different loads.

During the use of the forklift, the weight of the load multiplied by the distance separating it from the central support (called the inflection point) must be equal to or less than the weight of the forklift (which will act as a counterweight).

This will prevent excessive balancing, which could result in the fall of the load or the entire forklift.

Speaking more simply, the loads that a forklift transport must have less weight than the forklift itself.

The falls of loads with possible breakage of materials or injuries of the operators are the most common effect of ignorance of the load capacity of a forklift. This, of course, can be avoided with constant training for operators and employers.

You should not make the mistake of simply giving your operators the keys to the equipment and pointing out the work.

Forklift load capacity

How do I calculate the capacity of my forklift?

You can do a little research online looking for the model of our forklift.

In the specifications of the forklift, you will surely find its maximum load capacity, and if not, you will find its total weight.

- Multiplies the weight of the load by the distance that separates it from the central support.

- Always make sure that it is less than the total weight of the forklift.

- This ensures you have no problems with the load capacity of it.

Forklift safety

In all places where forklifts are used, they must exist

- Speed limits

- proper ground evaluation

- maintenance procedures to ensure safety

- guidelines on how to upload and download

- rules on how to transport materials correctly.

If all these precautions are taken into account, the chances of accidents at work and waste of materials will be minimized.

- Never carry a load that requires another employee to physically stabilize the load while moving the forklift.

- Never carry a load that exceeds the maximum capacity of the forklift.

- One sign of a heavy load is that the rear wheels rise when the load begins to rise.

- In these cases, lower the load immediately and change the lifting equipment or reduce the weight of the load.

- To maximize stability, the load must be hooked and centered on the forklift nails.

- The load should be supported against the back or vertical part of the nails.

- In addition, the length of the nails should always be of the length of the load, or greater.

- To prevent the load from tilting forward, the forklift mast must be tilted backward.

- If necessary, separate the nails before lifting the load.

- As a general rule, the wider, the better.

Forklift operator training

Tests and training to check the knowledge of the operator

- Trained operators must be able to demonstrate their ability, and their employer must test each operator with training.

- In this way, unsafe work practices are avoided.

- Employers must organize, during or after work hours, adequate training for anyone who is expected to operate or work with a forklift.

Initial training should include:

- Basic training so that the operator understands all the skills and knowledge he needs to operate the forklift safely.

- Specific job training adapted to the particular needs of the company, safety procedures and the type of work to be carried out.

- Familiarization training that must be completed at work and supervised to familiarize the apprentice with the forklift, the design of the site, among other aspects.

Forklift load center

Forklift Lifting Capacities

Load Size and Forklift Configuration

Forklift Lifting Capacity

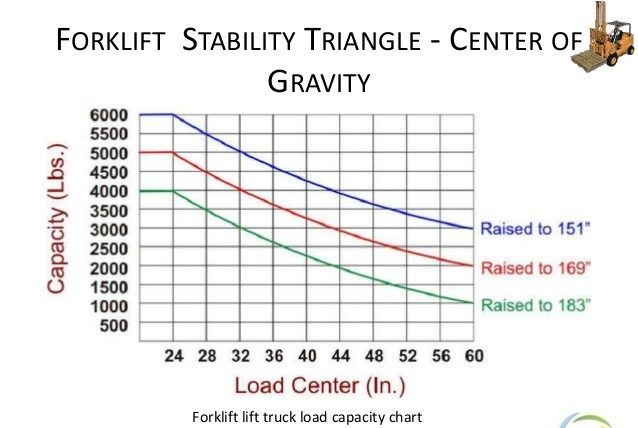

First, you have to consider the vertical and horizontal load center of the load that is being lifted, which essentially boils down to the load’s size and weight distribution. The longer, taller, and wider a load gets, the more it is going to affect a forklift’s center of gravity.

Since the load center also depends on the load’s weight distribution, an unevenly distributed load can also reduce the overall lifting capacity of the forklift.

Second, you have to consider the truck’s capabilities for lift, tilt, and load manipulation. Forklifts are plated as standard for the worst-case scenario, which includes all of these factors.

The ability to move the load further away from the forklift’s center of gravity by lifting, tilting, or performing a function as a side shift can all affect a forklift’s maximum capacity.

Forklift wheels

Speaking of attachments, there are more factors than just load manipulation that can affect capacity. An attachment’s effective thickness tells you how much further the load is pushed out from the truck’s fork face due to the attachment’s size. Its weight also plays a significant role as that increased weight out on the carriage reduces the load weight that the truck is capable of supporting.

- Different tire types and tread widths also play a significant role. A cushion tire versus a solid or air-filled pneumatic tire, for example, can have an effect on capacity.

- Wide tread and dual tire configurations can also increase a truck’s overall capacity due to the wider stance increasing the size of the forklift’s stability triangle.

Battery weight on an electric truck can also have an impact, which is one reason why using a battery that meets the truck’s minimum battery weight requirements is crucial to safe operation.

Forklift lifting capacity calculator

One thing to also keep in mind is that the forks, each attachment, mast, and carriage all have their own individual rated capacities. The capacity listed on your data plate cannot exceed the maximum capacity of any load-bearing component.

For example, if you have a 10,000 lb. capacity forklift with an attachment that is only capable of handling 5,000 lbs., your maximum rated capacity for the combination of these two is 5,000 lbs., which is what will be listed on your data plate.

It is important to remember that both ANSI and OSHA require data plates for each attachment and written approval from the forklift manufacturer for any modifications or alterations that may affect the capacity, stability, or safe operation of the forklift.

There are two different ways for a manufacturer to calculate capacity.

- The first is a tilt table test, which requires a forklift to be chained down to a tilt table and tested per the requirements.

- The second is for manufacturers to calculate the forklift’s capacity based on factors like the ones mentioned above.

Tested capacities are typically higher than calculated ones due to the conservative nature of the calculation, but this is not always the case.

Forklift data plate

he factors listed above are but a few of the primary factors that will be used to calculate a forklift’s rated capacity.

Ultimately, it’s best for you to work with your local authorized dealer when it comes to properly configure your forklift for your application and load handling needs.

This is especially important during the purchasing process, but also in regard to any modifications, you may make to your forklift after receiving it, including any attachments that you plan to use on the forklift or those acquired later on.

For more information regarding forklift modifications and best practices, be sure to read this piece on forklift field modifications.

Forklift questions

This forklift can carry 4,000 pounds at a 24 inches load center, but only 2,666 pounds at a 36 inches load center. Requirements and Recommended Practices: Estimate the safe load capacity with oversized loads.

It is easily calculated by measuring the load to be carried, and dividing by two (providing the load is evenly distributed, and positioned to butt up to the forklift backrest). You will often see a forklift truck’s nominal capacity quoted in a form such as 2,000kg @ 500mm load center.

-Industrial Reach Forklift Trucks.

-Industrial Counterbalance Forklifts.

-Rough Terrain Forklifts.

-Industrial Side Loader Forklifts.

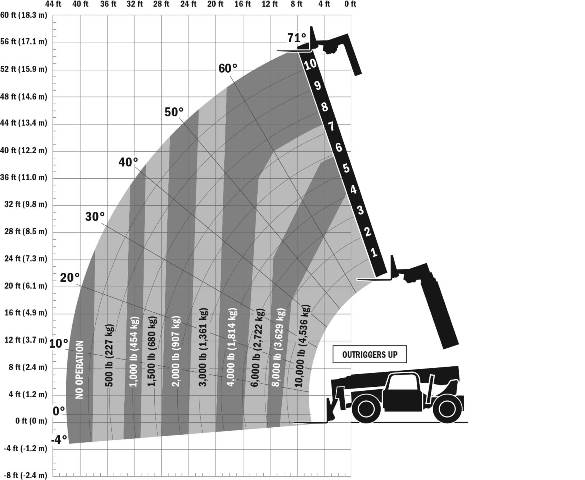

-Telescopic Handler Forklifts.

-Pedestrian Operated Pallet Trucks

A brand new, standard capacity electric warehouse forklift might cost approximately $15,000-$25,000 or more in addition to around $2,500 to $5,000 for a battery and charger. A comparable internal combustion forklift costs around $15,000-$30,000 and up.

As a general rule, forklifts have an economic life of approximately 10,000 to 12,000 hours. Again, this varies based on maintenance practices, operating conditions and the type of equipment used. In order to run an efficient and productive operation, the timely replacement of machinery is crucial.

The most read

Warehouse Lifting Equipment

What is a forklift? classes, types, how they work, parts, manual, electric, models, brands, industrial or electric.

How much does a forklift weigh?

How much does a forklift weigh? Is it important to know the weight of your forklift?

Forklift Size and Weight

Finding out the weight of a forklift is necessary to ensure the safety of your workers and your warehouse.

How heavy is a forklift?

Compare a forklift to a car and you’ll see that forklifts are unique vehicles with special challenges.