Tower Crane Hand Signals: Cranes have been in operation for more than 2,000 years, having been invented by the ancient Greeks. Today, there are a wide variety of cranes found at construction sites, such as truck-mounted cranes, rough terrain cranes and crawler cranes equipped with tracks.

The basic components of mobile cranes include a movable boom attached to a platform. The boom can be raised or lowered, as well as rotated to move a load horizontally. There are also cranes with telescoping booms. A spool with steel cables extends to the end of the boom and attaches to the load. A powerful motor provides the force to move the boom and raise or lower the load.

Most cranes also have heavy counterweights to help offset the weight of the load. Many cranes have outriggers to increase stability and help ensure that they remain level during operation.

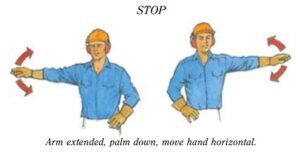

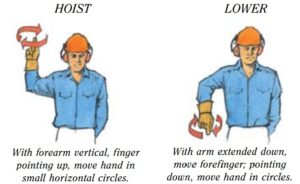

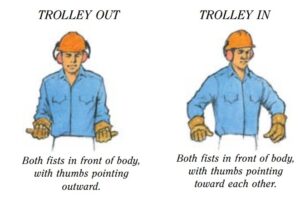

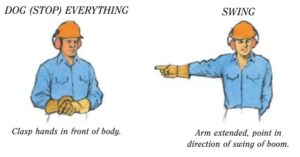

Crane operator hand signals

Using standard hand signals is the most widely used manner of signaling a crane operator. A hand signal chart can usually be found on the side of the crane or it should be conspicuously posted in the vicinity of where hoisting operations are being conducted.

Under the current OSHA crane standard there are only select instances when a signalperson is not required and for all those other times; having a top-flight signalperson should be a priority.

Every successful lifting operation is the result of planning and teamwork. The definition of teamwork is “a united effort by all to achieve the ultimate goal”. All lifting operations must be undertaken by a trained and competent team using a safe system of work established prior to the start of any lifting operation.

You as the tower crane operator play a vital role in the team and the aim of this guide is to give you essential practical advice to help you carry out this role successfully.

Should you have any doubts or questions regarding the information you must take this up with your employer before proceeding with lifting operations.

Hand signals in crane operation

Hand signals for tower crane:

Tower cranes are also widely used. The jibs on most tower cranes are secured in a horizontal position and rotate on their pedestal.

The load can be raised or lowered, and travel horizontally along the length of the jibs.

Tower Crane Limitations:

It is important to be aware of crane limitations, such as their load limits. The further the load is moved from the center of the crane, the less weight the crane can lift. For example, extending a telescopic boom reduces its lifting capacity. Also, lowering the boom decreases the crane’s load limit, because the load moves further away from the crane.

When a crane picks a load, the boom often deflects downwards. This is called boom deflection. This can present two hazards. It lowers the cranes lifting capacity by causing the load to be further from the crane. It can also cause the load to swing as it lifts off.

Tower crane signals

Crane Hand Signals:

Standardized hand signals are commonly used by the crane signal person. The signal person is the only one who should give signals to the operator. The only exception is if other personnel see a hazard, they can use the emergency stop signal. When the signal person gives directions to the operator, they must be from the operator’s perspective.

Tower crane voice signals

As with hand signals, voice communication between the signal person and the operator should be continuously maintained during crane movements. Directions should be given from the direct perspective of the operator.

Each voice signal must contain the following three elements, given in the following order: function (such as hoist, boom, etc.), direction; distance and/or speed; function, stop command. The operator, signal person and lift director (if there is one), must be able to effectively communicate in the language used.

Tower crane radio signals

Voice Signal Communication

In situations where hand signals are not appropriate, voice signals are an option. Portable radios are often used. They should be tested before crane operations begin and they should use a dedicated channel. The crane operator must use a hands-free device. Verbal signals should be short and clear. They should include three key elements, spoken in this order:

- The function and direction

- The distance and/or speed

- Function stop

The function names should be the same as the hand signals described earlier. Here are some examples of proper voice signals:

- Boom up. Slowly. Slowly. Boom stop.

- Lower load. 10 feet. 5 feet. 2 feet. Lower stop.

The function, such as Boom, Lower, Swing and Travel are spoken first, followed by the direction or speed. The signal to stop always has the function first, followed by a stop.

Construction hand signals

Construction site hand signals –

Non-standard and New Signals:

A situation may arise where standard signals don’t communicate all the information the operator needs lift. In that case, a new, non-standard signal may be used, as long as it is clearly understood by the operator, signal person and lift director.

General Safety Considerations:

An overview of basic safety precautions is described.

- Typical PPE will likely include hard hats, safety glasses, gloves, high visibility vests, and work boots.

- Before the lift begins, check that the load hook is centered over the load and that the rigging gear is properly set. Also, check that the load stays centered during the lift.

- Watch for power lines to be sure the boom or load doesn’t get too close.

- Watch the boom deflection closely to make sure it doesn’t exceed the load radius.

- Make sure other personnel stay out of the crane operating area and always keep yourself and others from under a suspended load.

- The rotation of the cab and counterweights presents a hazard. Stay well away from its rotation zone.

- Avoid using your hands to control a load. Use a tag line so you can stay a safe distance from the load.

- When an operator is moving a load horizontally, it may swing if the boom stops suddenly. Stay well away from swinging loads.

- Also, pay close attention to weather conditions.

- Lightning and strong side winds can produce serious hazards.

- The steel boom can act as a lightning rod and the wind pushing on the load and boom can make cranes unstable.

Hand signal for crane operation and their meaning

High Wind Conditions and Taking the Tower Crane Out of Service:

It is important that you monitor the wind speed constantly using the anemometer display in the cab. This will give you early warning of rising wind speeds and enable you to take action to take the tower crane out of service and descend the tower whilst it is still safe to do so. If the wind is gusting around the limiting wind speed it may be appropriate, following consultation with your supervisor, to remain in the cab whilst establishing if the wind speed is rising or falling.

Crane safety hand signals

Crane safety hand signals: You should report the wind speed to your supervisor on-site on a regular basis. Where the wind speed is rising this will allow the site plenty of opportunities to plan concrete deliveries etc, before the crane has to be taken out of service.

The anemometer or other windspeed indicators must be included in the daily pre-use checks.

Putting the crane in the out-of-service condition generally includes ensuring that the jib is free to “weather vane” when out of service so that the minimum wind area is presented to the prevailing wind.

On luffing jib tower cranes it is also important that the jib is left at the correct out of service radius (specified by the crane manufacturer, which is not always the minimum radius. This will ensure that there is sufficient wind area to enable the crane to “weather vane”.

When taking the crane out of service on multi crane sites you must ensure that the crane in free slew will not enter the area of other cranes that are still operating.

Tower cranes must not be left out of service with a load on the hook and the hook must always be fully raised.

Tower Crane Hand Signals

A hand signal chart can usually be found on the side of the crane or it should be conspicuously posted in the vicinity of where hoisting operations are being conducted.

During crane operation, only one person can give signals, unless it’s for an emergency stop – then anyone on the job site can give the signal. Once the qualified signal person is identified, the signal person and the crane operator must identify each other prior to giving any signals.

Anyone who becomes aware of a safety problem must alert the operator or signal person by giving the stop or emergency stop signal.

The most read

Crane Hand Signal Chart

What are the proper hand signals for cranes?

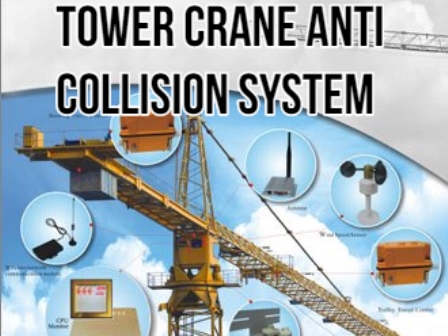

Tower Crane anti-collision System

In the worksite, multiple tower cranes are now working within one building or one construction site. The collision between the tower cranes, sometimes stalling the project..

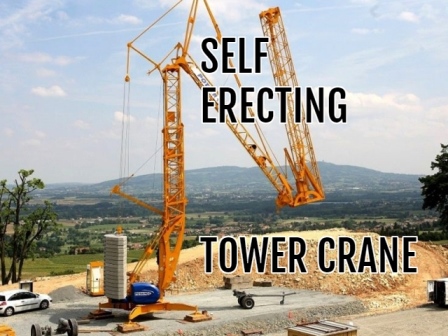

Self Erecting Tower Crane

A self-erecting tower crane is compact, easy to erect and operate, and have several transport options. Wireless remote controls, quiet and efficient electric motors, state-of-the-art variable frequency motor drives and overload protection systems are standard.